A bus duct with high comprehensive protection level

A technology of protection level and busway, which is applied in the field of busway, can solve the problems of unable to guarantee normal and stable power transmission, poor fire resistance of refractory materials, deformation of refractory busway, etc., to improve comprehensive fire protection performance, enhance sealing performance and fire protection Effects of performance, protective insulation and fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

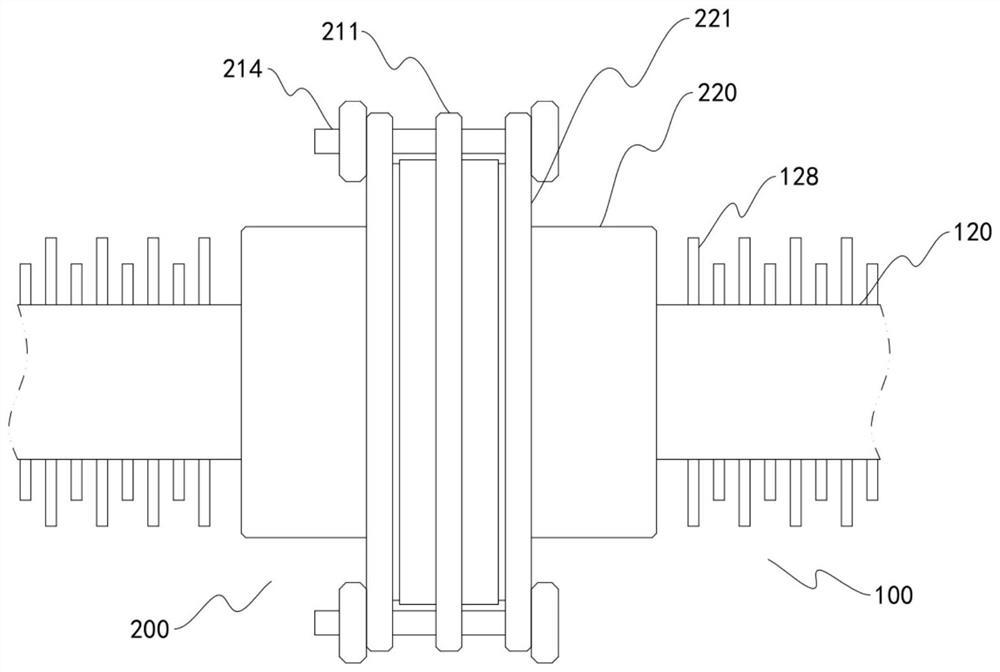

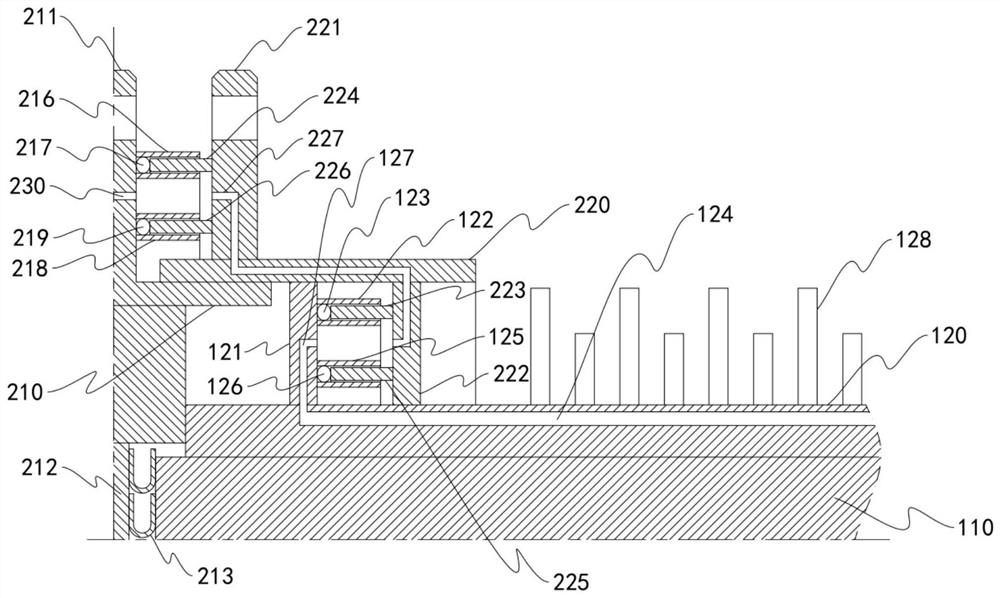

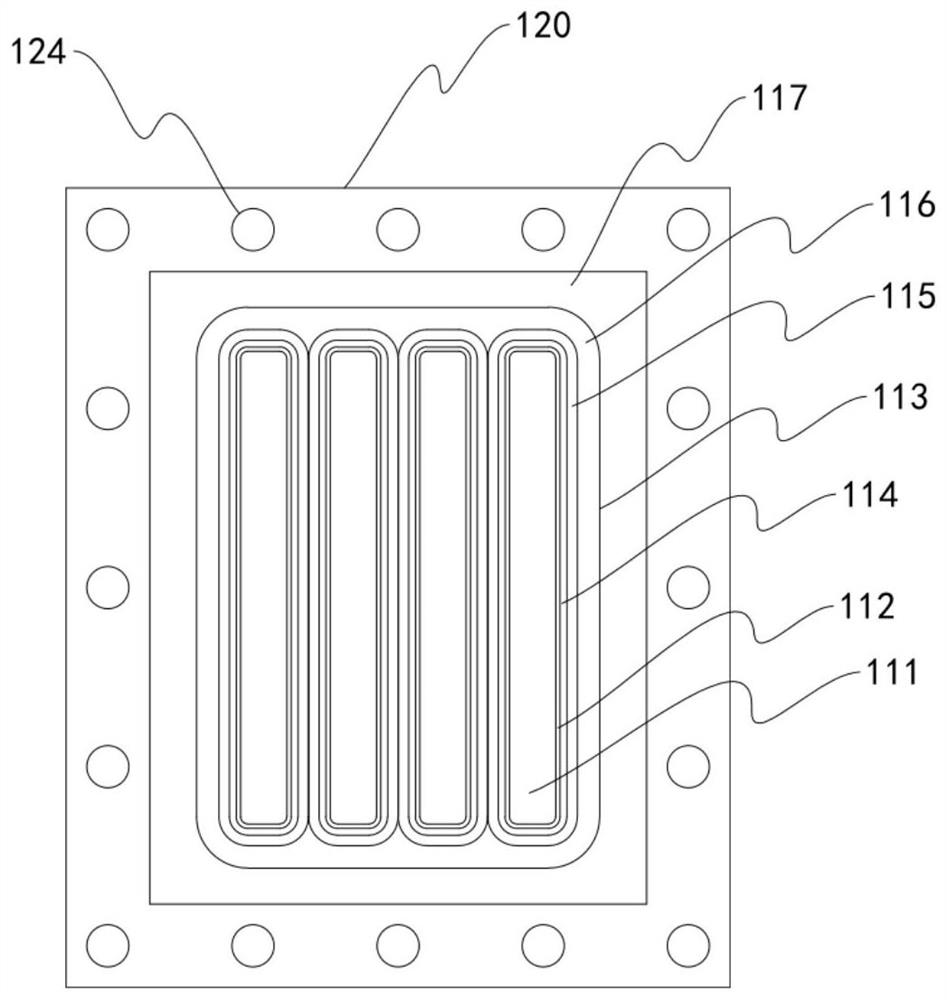

[0027] Such as Figure 1-4 As shown, a bus duct with a high comprehensive protection level includes a bus duct body 100 and a connector 200. The bus duct body 100 includes a bus bar 110 and a metal shell 120 arranged outside the bus bar 110. The bus bar The outer surface of 110 is provided with an insulating protective layer 112, the outer surface of the insulating protective layer 112 is provided with a mineral refractory layer 113, and the outer surface of the mineral refractory layer 113 and the inner wall of the metal shell 120 are provided with A ceramic silicone rubber waterproof and moisture-proof layer 117, the connector 200 includes a rectangular metal pipe body with openings at both ends, and the metal pipe body includes a middle pipe body 210 and end pipe bodies 220 symmetrically arranged at both ends of the middle pipe body 210, One end of the two end pipe bodies 220 is respectively slidably sleeved on the periphery of both ends of the middle pipe body 210, and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com