Application of a black phosphorus carbon nanotube composite as a non-contact electrostatic response actuator

A carbon nanotube and composite material technology, applied in electrostatic motors, electrostatic generators/motors, generators/motors, etc., can solve the problem of difficult acquisition of stimulus sources, achieve diverse forms of motion, increase interlayer electron conduction, The effect of increasing the layer width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

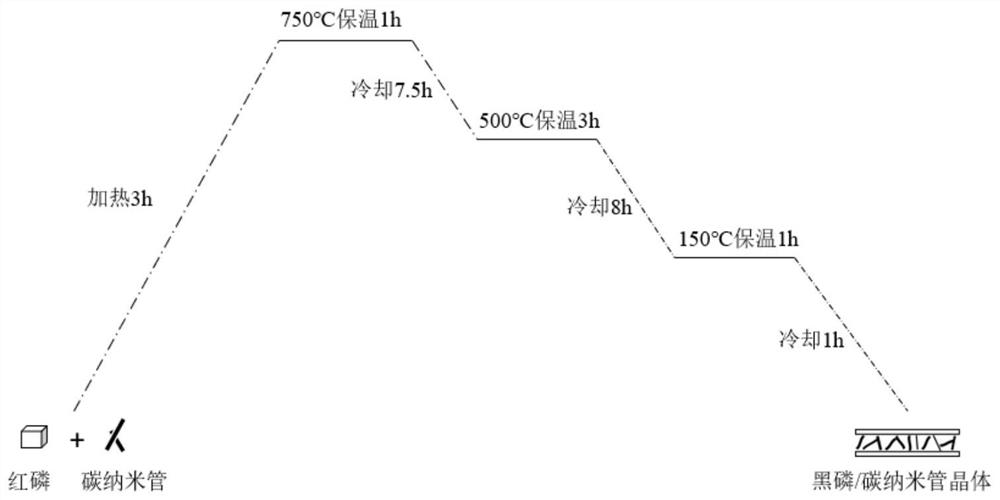

[0046] The preparation method of black phosphorus carbon nanotube composite material, the preparation flow chart is as follows figure 2 shown.

[0047](1) Pack 500mg of red phosphorus, 5mg of carbon nanotubes and 30mg of tin and tin tetraiodide in a vacuum quartz tube for vapor phase conversion growth. First, heat the furnace tube to 750°C within 3 hours and keep it at this temperature 1 hour; in the second step, cool the furnace tube to 500°C within 7.5 hours and keep it warm for 3 hours. The 3rd step, furnace tube is cooled to 150 ℃ and is incubated 1 hour in 8 hours, furnace tube is cooled to room temperature at last, makes black phosphorus carbon nanotube crystal; Wherein the mass ratio of tin and tin tetraiodide is 2: 1;

[0048] (2) Disperse 100 mg of black phosphorus carbon nanotube crystals in 100 mL of acetonitrile, add 240 mg of 4-nitrobenzenediazo, and keep for 30 minutes. Then, the mixture was filtered and washed with acetonitrile to obtain passivated black pho...

Embodiment 2

[0055] Preparation method of black phosphorus carbon nanotube composite material

[0056] (1) Pack 500mg of red phosphorus, 5mg of carbon nanotubes and 30mg of tin and tin tetraiodide in a vacuum quartz tube for vapor phase conversion growth. First, heat the furnace tube to 750°C within 3 hours and keep it at this temperature 1 hour; in the second step, cool the furnace tube to 500°C within 7.5 hours and keep it warm for 3 hours. The 3rd step, furnace tube is cooled to 150 ℃ and is incubated 1 hour in 8 hours, furnace tube is cooled to room temperature at last, makes black phosphorus carbon nanotube crystal; Wherein the mass ratio of tin and tin tetraiodide is 2: 1;

[0057] (2) Disperse 100 mg of black phosphorus carbon nanotube crystals in 100 mL of acetonitrile, add 240 mg of 4-nitrobenzenediazo, and keep for 30 minutes. Then, the mixture was filtered and washed with acetonitrile to obtain passivated black phosphorus carbon nanotube crystals;

[0058] (3) Disperse the pa...

Embodiment 3

[0064] The difference between this embodiment and Embodiment 1 is that the mass ratio of black phosphorus to carbon nanotubes is adjusted to 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com