Ethylene/alpha-olefin copolymer and preparation method therefor

A technology of olefin copolymer and olefin comonomer, which is applied in the field of ethylene/α-olefin copolymer and its preparation, can solve the problems of uneven molecular weight dispersion state, unstable physical properties, rough extrusion appearance, etc., and achieve excellent impact Effects of strength and mechanical properties, improved reaction efficiency, excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] Meanwhile, the ethylene / α-olefin copolymer having the above physical properties can be produced by a production method comprising injecting hydrogen at 45 to 100 cc / min in the presence of a catalyst composition comprising a transition metal compound of the following formula 1 to polymerize ethylene and alpha-olefin-based monomers. Accordingly, another aspect of the present invention provides a method for preparing an ethylene / α-olefin copolymer.

[0080] [Formula 1]

[0081]

[0082] In formula 1, R 1 is hydrogen; alkyl of 1 to 20 carbon atoms; cycloalkyl of 3 to 20 carbon atoms; alkenyl of 2 to 20 carbon atoms; alkoxy of 1 to 20 carbon atoms; atoms; arylalkoxy of 7 to 20 carbon atoms; alkylaryl of 7 to 20 carbon atoms; or arylalkyl of 7 to 20 carbon atoms,

[0083] R 2a to R 2e each independently hydrogen; halogen; alkyl of 1 to 20 carbon atoms; cycloalkyl of 3 to 20 carbon atoms; alkenyl of 2 to 20 carbon atoms; alkoxy of 1 to 20 carbon atoms; or an aryl grou...

Embodiment 1

[0169] Into a 1.5 L autoclave continuous process reactor was charged hexane solvent (5.0 kg / h) and 1-octene (1.00 kg / h) and the top of the reactor was preheated to a temperature of 150°C. At the same time, inject triisobutylaluminum compound (0.05mmol / min), the transition metal compound (1a) (0.40μmol / min) prepared in the synthesis example as a catalyst, and dimethylanilinium tetrakis (penta Fluorophenyl) borate accelerator (1.20 μmol / min). Then, ethylene (0.87kg / h) and hydrogen (50cc / min) were injected into the autoclave reactor, and the copolymerization reaction was continuously performed for 60 minutes or more while maintaining a pressure of 89 bar and a polymerization temperature of 125°C to prepare a copolymer .

[0170] Then, the remaining ethylene gas was vented, and the copolymer-containing solution thus obtained was dried in a vacuum oven for more than 12 hours. The physical properties of the copolymer thus obtained were measured.

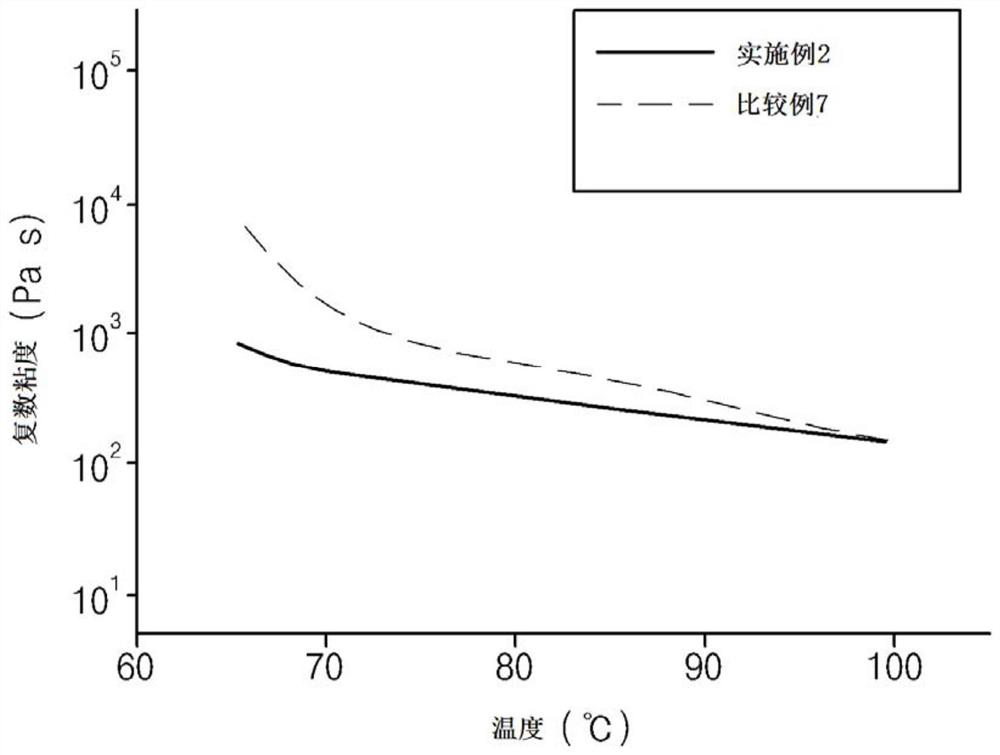

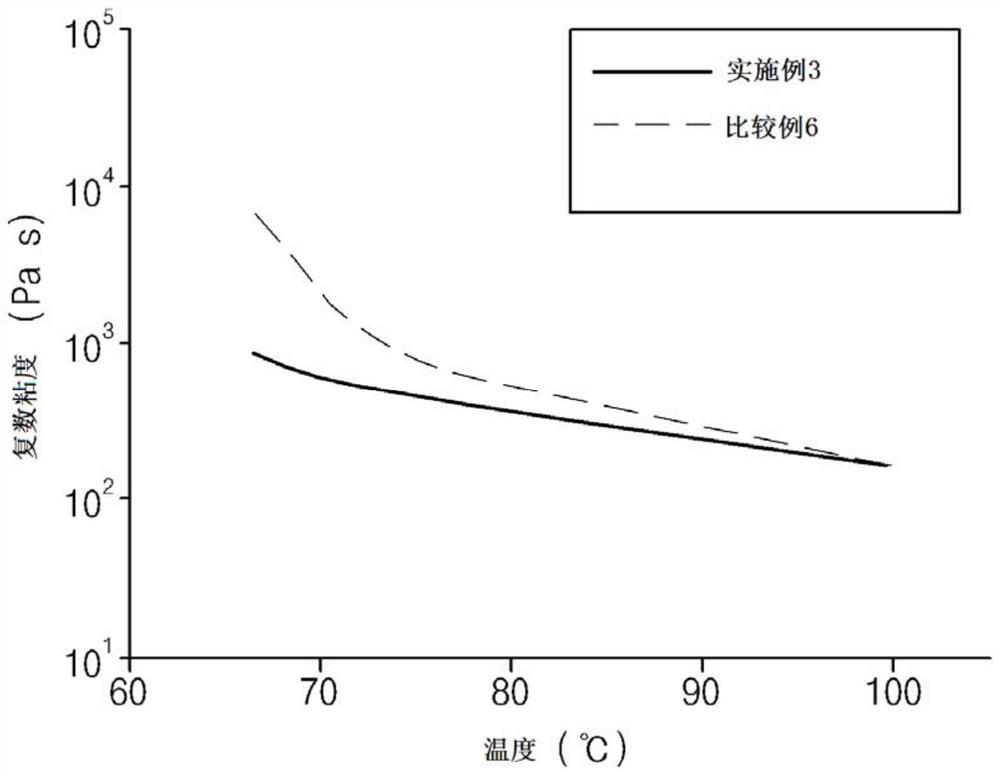

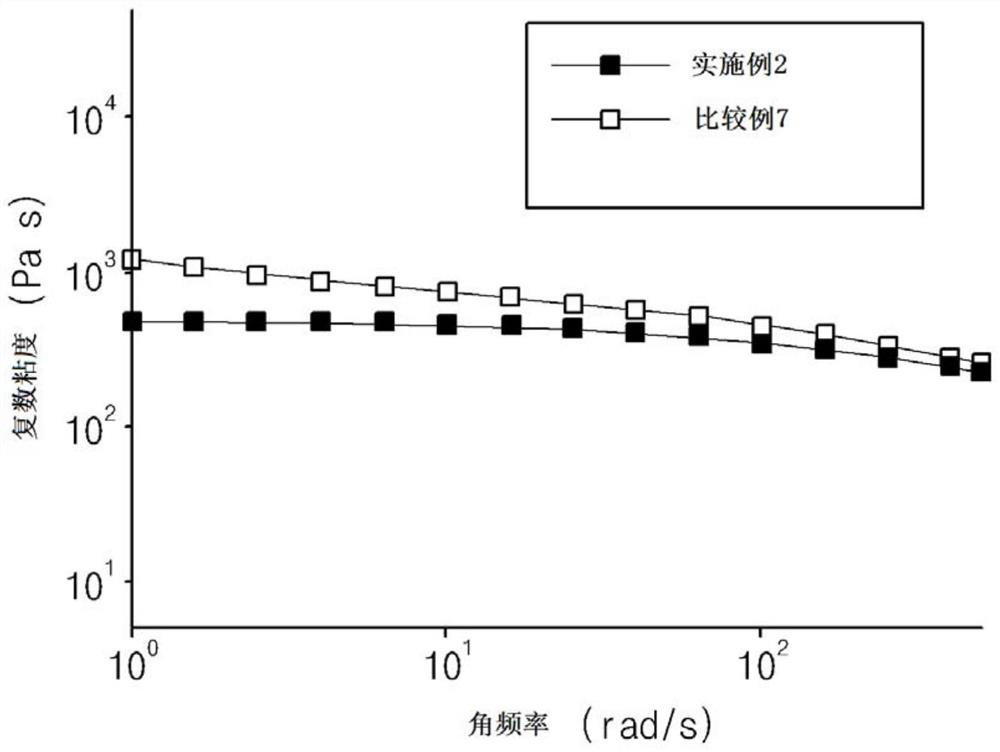

Embodiment 2 to 7 and comparative example 1 to 7

[0172] A polymer was prepared by the same method as in Example 1 except that the reactant raw materials were injected in the amounts listed in Table 1 below.

[0173] [Table 1]

[0174]

[0175] *In comparative examples 6 and 7, [Me 2 Si(Me 4 C 5 )NtBu]Ti(CH 3 ) 2 used as a catalyst.

[0176] [Evaluation of Physical Properties of Olefin Polymers]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com