Repair method of aeroengine blade

An aero-engine and repair method technology, applied in the direction of improvement of process efficiency, additive processing, energy efficiency, etc., can solve the problems of unable to form solidified structure with directional growth, unfavorable repair of high-temperature mechanical properties of blades, etc., and achieve good mechanical properties , reducing the effect of transverse grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

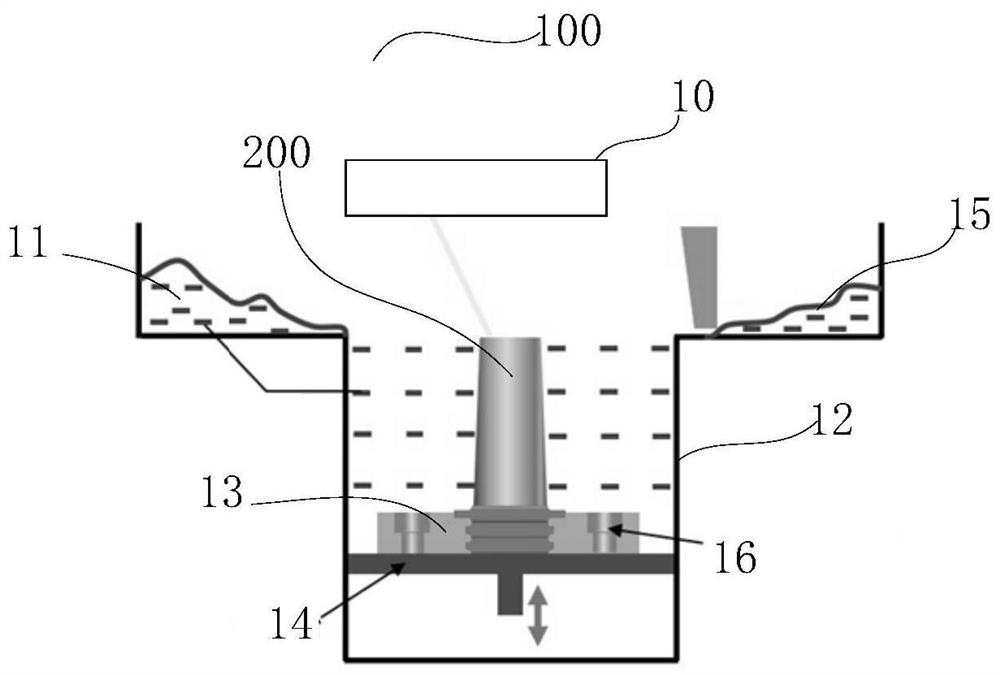

[0035] Such as figure 1 As shown, the laser molding module includes an optical window 10, a powder spreading device 11, a molding cavity 12, a substrate 13, a lifting mechanism 14, and a powder scraping device 15; the optical window 10 is located above the molding cavity 12, and a lifting mechanism is installed in the molding cavity 12 14. The substrate 13 is horizontally installed on the lifting mechanism 14, the powder spreading device 11 is located on one side of the molding cavity 12, and the powder scraping device 15 is located on the other side of the molding cavity 12.

[0036] It is worth mentioning that the lifting mechanism 14 can be a piston, and a groove for fixing the workpiece to be processed is opened in the middle of the base plate 13 , and a mounting hole is opened on the base plate 13 , and then fixed on the lifting mechanism 14 by bolts 16 .

[0037] The laser light emitted by the laser reaches the scanning system after passing through the light guide system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com