Multi-dimensional expansion robot

A robot, multi-dimensional technology, applied in the directions of manipulators, conveyor objects, transportation and packaging, etc., can solve the problems of small space operation range, high space occupancy rate, small carrying capacity, etc., to widen the working range and low space occupancy rate. , reliable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific structure of the present invention is further described below:

[0026] Explain the structural installation relationship and function of each component of the patent of the present invention:

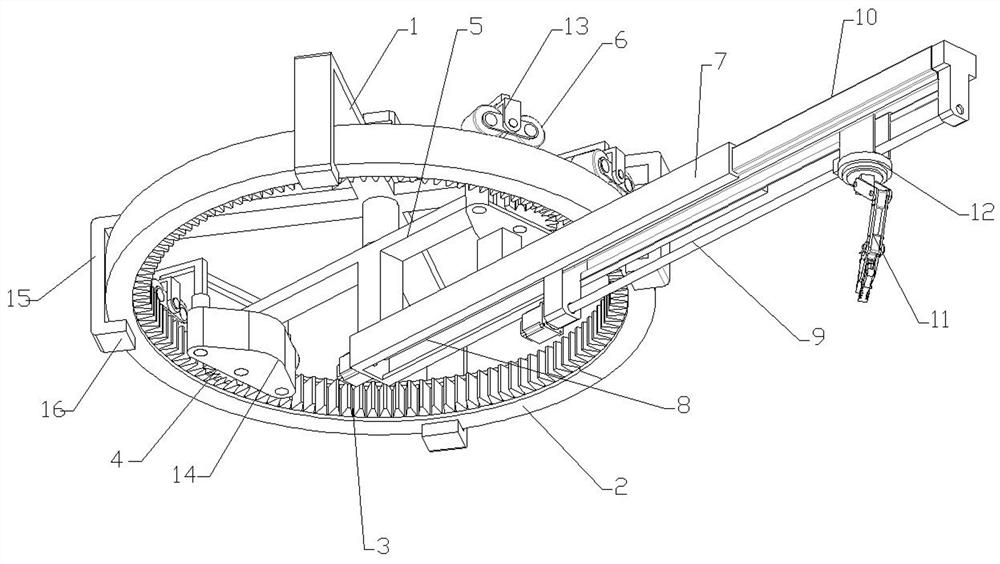

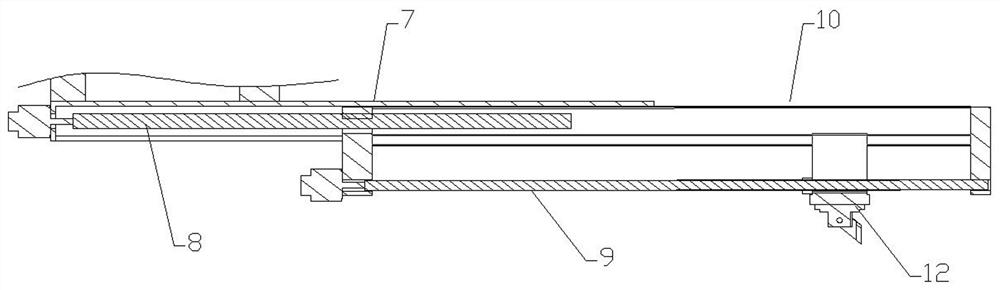

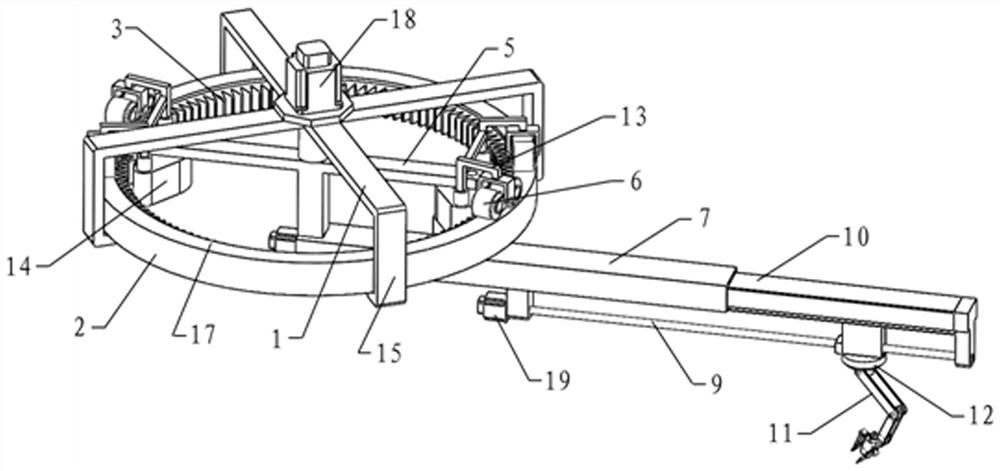

[0027] The device includes a hoisting installation frame, a circular track, a circular driving device, a linear extension mechanism, a linear movement mechanism and an end effector.

[0028] Hoisting installation frame: The hoisting installation frame is used for the installation and fixing of multi-dimensional expansion robots, and is fixed above the interior of the factory building or on the top of the open-air hoisting bracket by means of hoisting installation. In the present invention, the hoisting installation frame is a cross, and the four ends of the cross extend downwards from the hanging plate, and the bottom of the hanging plate stretches out the supporting plate to support the bottom of the circular track and fix it.

[0029] The circular track is a ring-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com