Membrane shell material used for multi-ribbed floor system, membrane shell containing membrane shell material and preparation method for membrane shell

A technology of dense ribbed floor and membrane shell, which is applied to floors, building components, buildings, etc., can solve the problems of inconvenient transportation and construction, difficult to reuse, long molding cycle, etc., to save transportation costs, shorten molding cycle, increase The effect of product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

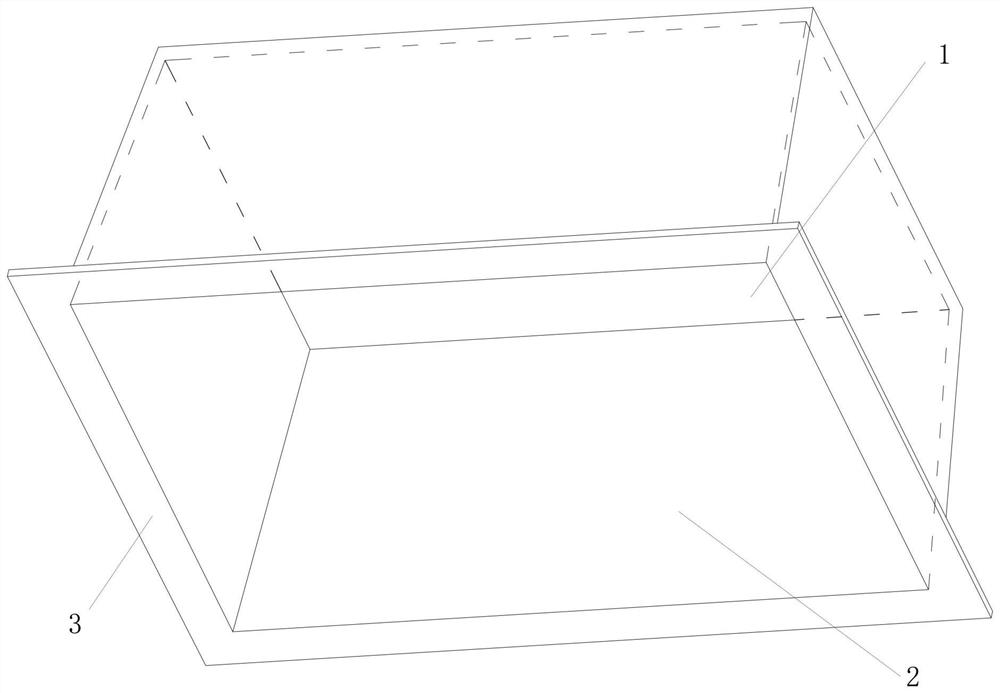

Image

Examples

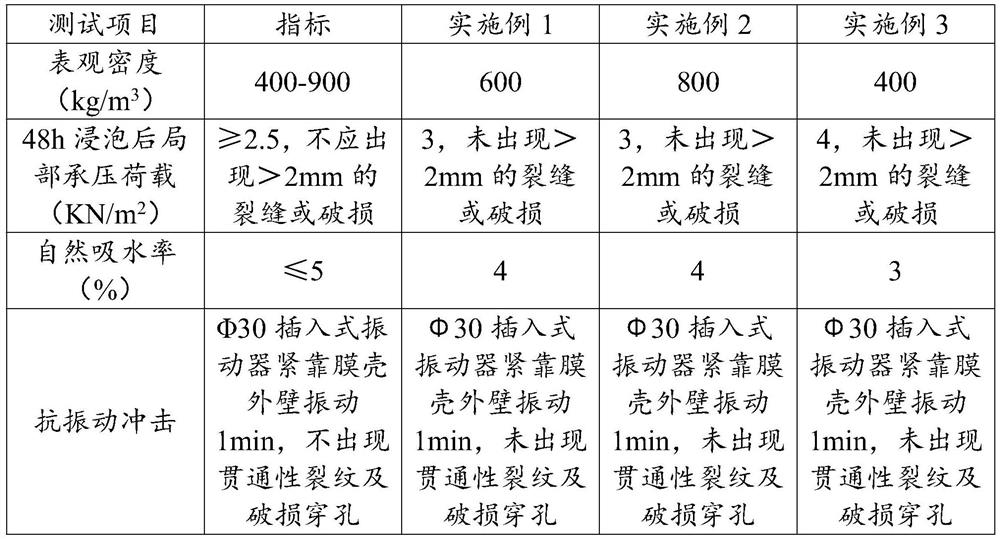

Embodiment 1

[0063] Membrane shell materials for ribbed roofs, including the following raw materials: 40kg of ferroaluminate cement, 20kg of fluorogypsum, 20kg of composite gypsum, 6kg of fly ash, 10kg of glass fiber mesh cloth, 5kg of chopped glass fiber, glass water 10kg, sodium sulfate 2kg and water 40kg;

[0064] A method for preparing a membrane shell for a ribbed floor, specifically comprising the following steps:

[0065] (1) Take each raw material by the parts by weight of the membrane shell material for the above-mentioned ribbed floor, and divide the glass level into two parts, and the glass fiber mesh cloth into three parts;

[0066] (2) Alumina ferrite cement, fluorogypsum, composite gypsum, fly ash and the first glass of water were stirred for 5 minutes, and allowed to stand for 5 minutes to obtain slurry A;

[0067] (3) Add chopped glass fiber, the second part of glass water, sodium sulfate and water into the slurry A and continue to stir for 5 minutes to obtain the slurry B...

Embodiment 2

[0070] Membrane shell materials for ribbed roofs, including the following raw materials: 60kg of ferroaluminate cement, 25kg of fluorogypsum, 25kg of composite gypsum, 10kg of fly ash, 15kg of glass fiber mesh cloth, 10kg of chopped glass fiber, glass water 20kg, magnesium sulfate 5kg and water 60kg;

[0071] A method for preparing a membrane shell for a ribbed floor, specifically comprising the following steps:

[0072] (1) Take each raw material by the parts by weight of the membrane shell material for the above-mentioned ribbed floor, and divide the glass level into two parts, and the glass fiber mesh cloth into three parts;

[0073] (2) Alumina ferrite cement, fluorogypsum, composite gypsum, fly ash and the first glass of water were stirred for 10 minutes, and allowed to stand for 10 minutes to obtain slurry A;

[0074] (3) Add chopped glass fiber, the second part of glass water, magnesium sulfate and water into the slurry A and continue to stir for 10 minutes to obtain t...

Embodiment 3

[0077] Membrane shell materials for ribbed roofs, including the following raw materials: 50kg of ferroaluminate cement, 22kg of fluorogypsum, 22kg of composite gypsum, 8kg of fly ash, 12kg of glass fiber mesh cloth, 8kg of chopped glass fiber, glass water 15kg, sodium carbonate 3kg and water 50kg;

[0078] A method for preparing a membrane shell for a ribbed floor, specifically comprising the following steps:

[0079] (1) Take each raw material by the parts by weight of the membrane shell material for the above-mentioned ribbed floor, and divide the glass level into two parts, and the glass fiber mesh cloth into three parts;

[0080] (2) Alumina ferrite cement, fluorogypsum, composite gypsum, fly ash and the first glass of water were stirred for 8 minutes, and allowed to stand for 8 minutes to obtain slurry A;

[0081] (3) Add chopped glass fiber, the second part of glass water, sodium carbonate and water into the slurry A and continue to stir for 8 minutes to obtain the slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com