Polyester melt conveying heat energy saving system

A polyester melt and energy-saving system technology, which is applied in the field of polyester spinning production, can solve problems such as energy waste and pollution of the working environment, and achieve the effects of low-carbon production, high product quality, and improvement of the company's economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

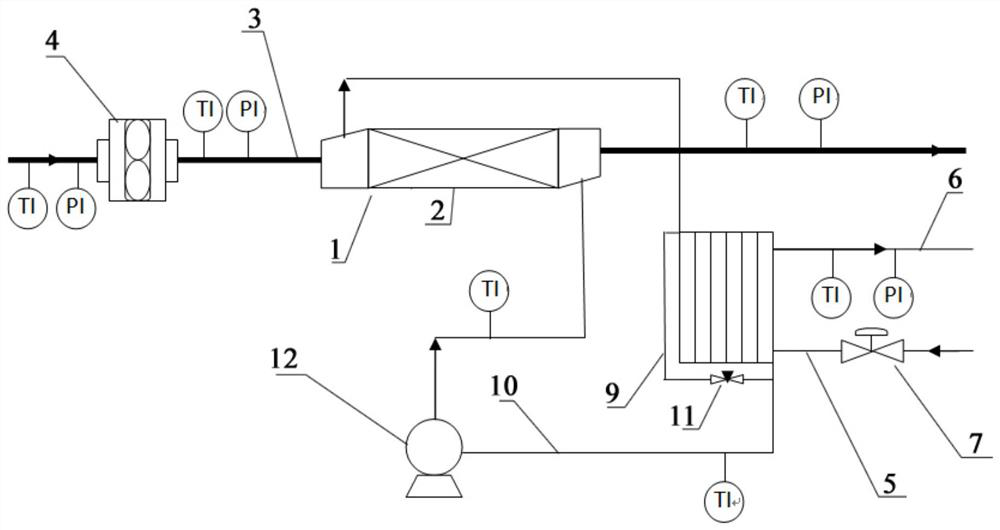

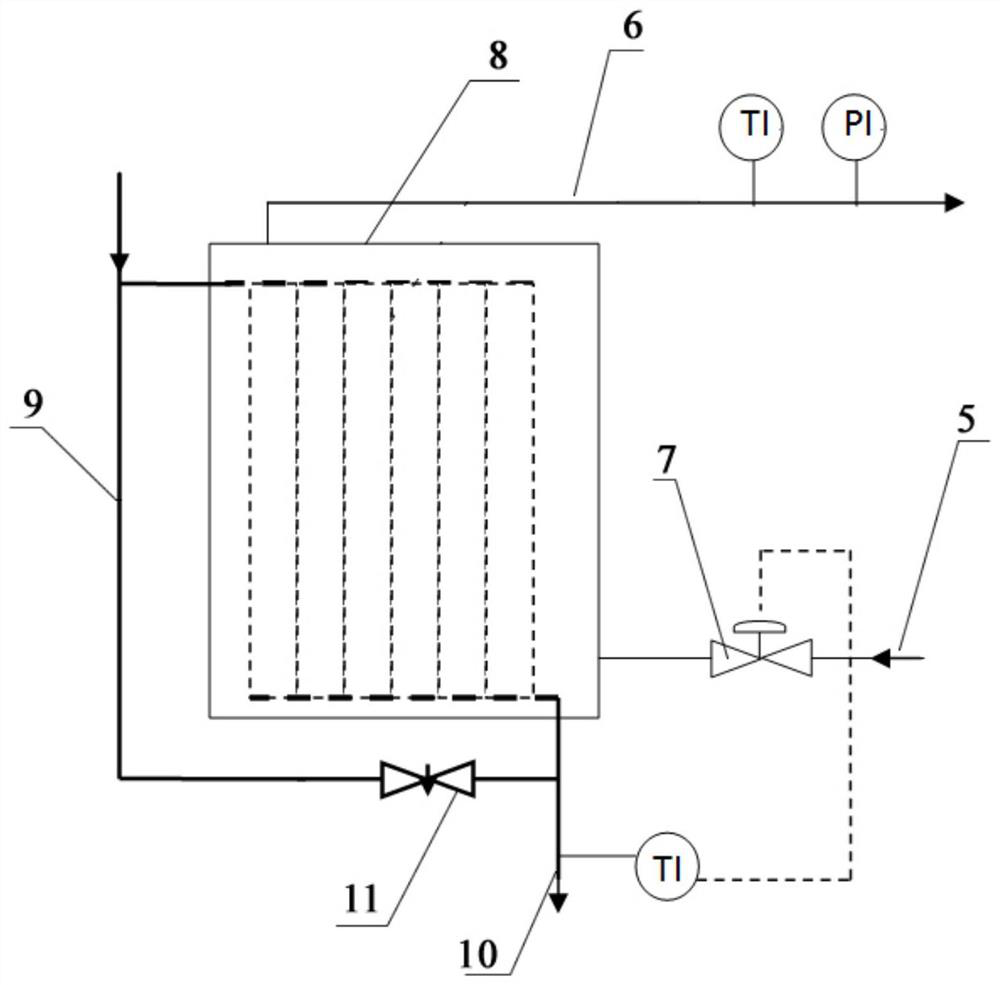

[0018] Such as Figure 1-2 Shown is a specific embodiment of a heat energy saving system for polyester melt delivery, which is a heat energy saving system for polyester melt delivery, including a melt cooler 1, and the melt cooler 1 includes a housing 2 and a The shell 2 is composed of No. 1 pipe for heat exchange. The space in shell 2 except for No. 1 pipe constitutes the heat exchange shell. The inlet and outlet of the heat exchange shell are respectively connected with a The melt pipeline 3 of the ester melt, the melt pipeline 3 connected to the inlet end of the heat exchange shell side is connected with a melt booster pump 4 to boost the pressure, and the existing polyester melt direct spinning device is characterized by the melt The transportation pipeline is long, and there are factors such as p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com