Lithium metal electrode and preparation method and application thereof

A lithium metal electrode and lithium sheet technology, applied in the field of lithium metal electrode and its preparation, can solve the problems of stress change, thermal runaway, dead lithium and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

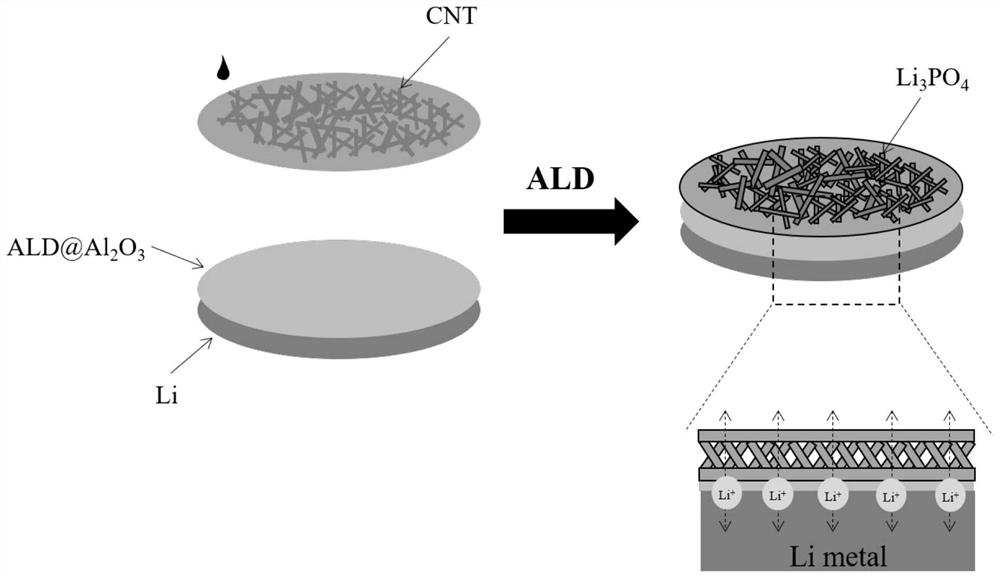

[0038] The present invention also provides a preparation method of the lithium metal electrode described in the above technical solution, comprising the following steps:

[0039] Depositing Al on the surface of lithium flakes by atomic layer deposition 2 o 3 , get Al 2 o 3 Floor;

[0040] In the Al 2 o 3 The surface of the layer is coated with a carbon nanotube dispersion to obtain a carbon nanotube layer;

[0041] Adopt atomic layer deposition method, deposit Li on the surface of described carbon nanotube layer 3 PO 4 layer to obtain the lithium metal electrode.

[0042]In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0043] The present invention adopts the atomic layer deposition method to deposit Al on the surface of the lithium sheet 2 o 3 , get Al 2 o 3 Floor. In the present invention, the deposited Al 2 o 3 The process is preferably as follows: i...

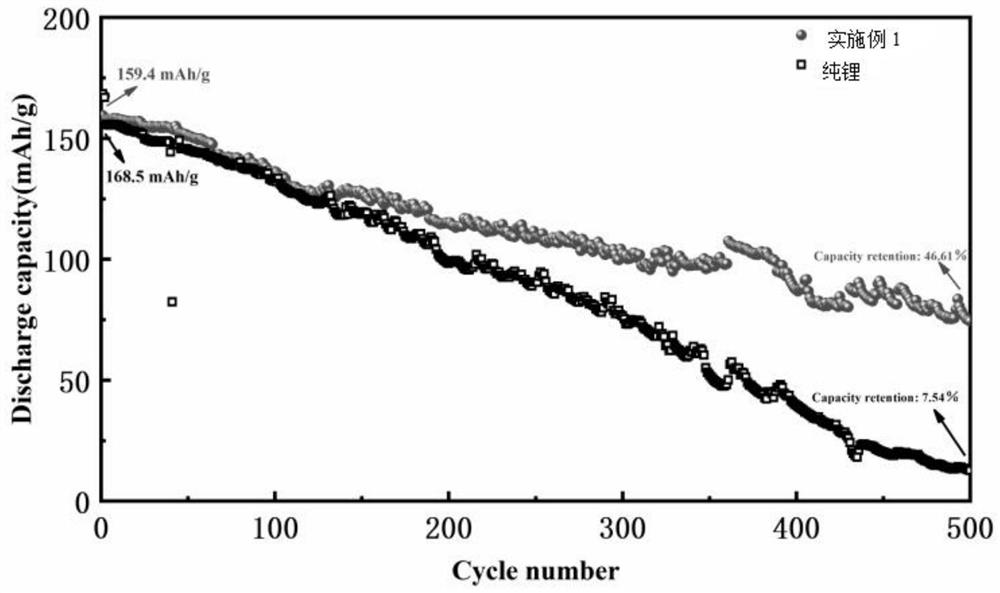

Embodiment 1

[0071] Place a lithium sheet with a thickness of 0.5mm in the vacuum reaction chamber of the glove box combined with atomic layer deposition equipment, and then seal the reaction chamber. The temperature of the vacuum reaction chamber is 150 ° C. The system pipeline, trimethylaluminum and The temperature of deionized water is room temperature;

[0072] Turn on the vacuum mechanical pump to evacuate the system pipeline and vacuum reaction chamber to less than 0.1Pa, feed trimethylaluminum for 0.2s, deposit for 0.5s, feed cleaning gas, and purge the residual gas and by-products after the reaction for 15s ;Introduce deionized water for 0.2s, deposit for 0.5s, inject cleaning gas, and purge the residual gas and by-products after the reaction for 15s; after cleaning, vacuumize until the pressure value of the vacuum reaction chamber and system pipeline is less than 0.1Pa , cycle the above operation 50 times to obtain Al with a thickness of 5nm 2 o 3 Floor;

[0073] Mix 10 mg of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com