Assemblable biochemical pool defoaming device and defoaming method

A technology of defoaming device and biochemical pool, applied in chemical instruments and methods, biological water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of limited foam reduction, high price, secondary environmental pollution, etc. The effect of improving water purification efficiency, improving oxygenation efficiency and reducing foam content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

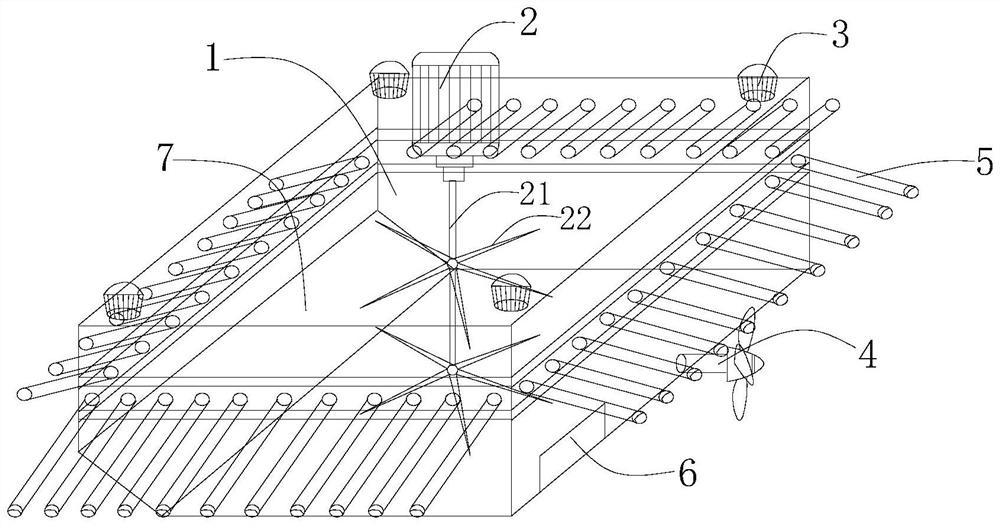

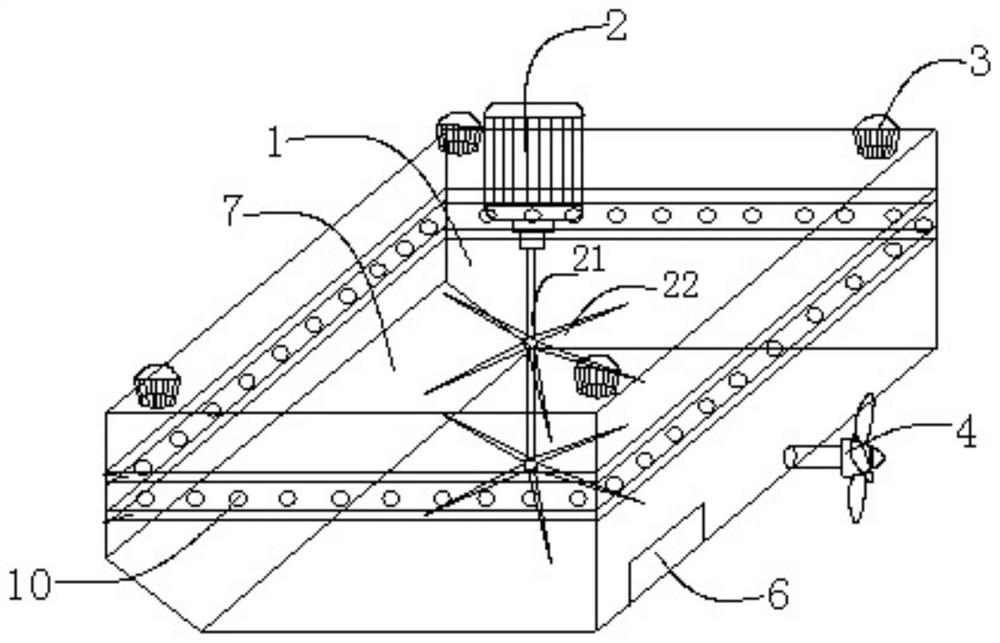

[0038] see figure 1 and figure 2, a biochemical pool defoaming device that can be assembled, including a defoaming unit 1, a foam collecting device and a stirring defoaming device are arranged in the defoaming unit 1, the defoaming unit 1 is designed as a polyhedral structure, and the defoaming unit 1 is designed as a polyhedral structure. A propeller 4 is installed at the driving end of the foam unit 1 , and a wedge plate 7 is arranged inside the defoaming unit 1 , and the installation position of the wedge plate 7 is on the side opposite to the propeller 4 . The propeller 4 is used to drive the defoaming unit 1 to move, and is the power source of the defoaming unit 1 .

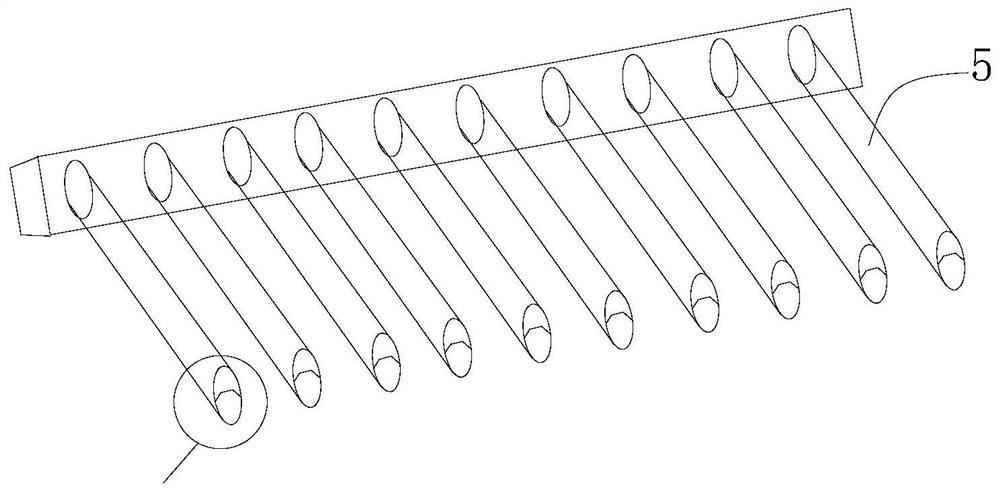

[0039] see figure 1 , image 3 and Figure 5 The foam collecting device is arranged on the side wall of the defoaming unit 1, the stirring and defoaming device is arranged in the inner cavity of the defoaming unit 1, and the foam collecting device includes several foam collecting pipes 5, the defoaming ...

Embodiment 2

[0045] see Figure 4 and Figure 5 , this embodiment serves as a further optimization of Embodiment 1, on the basis of which, adjacent defoaming units 1 can be connected in a front-to-back direction or in a left-right direction ( Figure 7 and Figure 8 As shown), the outer wall of the defoaming unit 1 is provided with connecting guide rails, and the connecting guide rails include an upper slideway 51 and a lower slideway 52, and the upper slideway 51 and the lower slideway 52 are respectively arranged in the built-in foam collection through hole On the upper and lower sides of the position of 10, the upper slideway 51 and the slideway 52 are respectively provided with an upper slideway clamping groove 55 and a slideway clamping groove 56, and the adjacent defoaming units 1 pass through the slideway buckle 54 Butt the corresponding upper slide rail slot 55 or slide rail slot 56 . One side of the foam collecting pipe 5 on the adjacent defoaming unit 1 is set as the slideway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com