Method for reducing cow breeding wastewater treatment load

A breeding wastewater treatment load technology, applied in animal husbandry wastewater treatment, water/sewage treatment, special compound water treatment, etc., can solve problems affecting activated sludge contact, affecting biological treatment process, affecting liquid properties, etc., to achieve cost Low, ensure normal operation, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] On April 25, 2021, the water quality indicators of a dairy cow breeding wastewater were measured as follows:

[0054] COD (mg / L) SS(mg / L) NH3-N(mg / L) TN (mg / L) TP (mg / L) Viscosity (mPa·S) 47600 35400 1820 3300 460 10

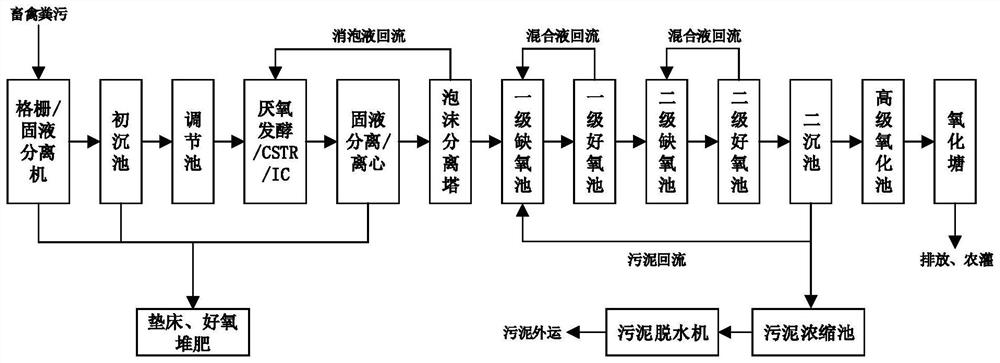

[0055] This embodiment adopts figure 1 Process shown

[0056] (1) First pass the wastewater from dairy farms through a 5-20mm grille / solid-liquid separator to filter out large-sized forage debris, animal hair, etc., and the primary sedimentation tank initially removes sediment and organic matter with a large specific gravity in the wastewater , and then transported to the anaerobic reactor through pipelines;

[0057] (2) After the anaerobic fermentation treatment of the anaerobic reactor, the organic matter is fully degraded, and the generated biogas can be used as heating for the sewage treatment system, and the excess biogas can be used as clean energy for comprehensive utilization; the waste inside the anaerobic react...

Embodiment 2

[0073] On May 18, 2021, the water quality indicators of a dairy cow breeding wastewater are as follows:

[0074] COD (mg / L) SS(mg / L) NH3-N(mg / L) TN (mg / L) TP (mg / L) Viscosity (mPa·S) 48600 34240 1820 3540 380 9

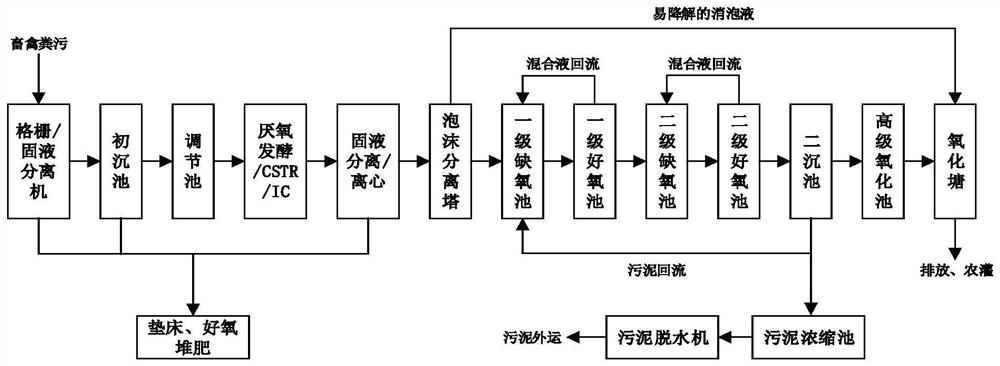

[0075] This embodiment adopts figure 2 Process shown

[0076] (1) First filter the wastewater from the dairy farm through a 5-20mm grid / solid-liquid separator;

[0077] (2) Send the waste inside the anaerobic reactor into a 50-200 mesh centrifugal solid-liquid separator to obtain the separated solid as a compost material, and the liquid enters the subsequent treatment process;

[0078] (3) The hydraulic retention time of the anaerobic reactor is 15-35 days, and the temperature is maintained at 25-40°C;

[0079] The water quality of the anaerobic reactor effluent on June 21, 2021 is as follows:

[0080] COD (mg / L) SS(mg / L) NH3-N(mg / L) TN (mg / L) TP (mg / L) Viscosity (mPa·S) 27600 23400 2260 3700 420 9.5 ...

Embodiment 3

[0093] On April 15, 2021, the water quality indicators of a dairy cow breeding wastewater are as follows:

[0094] COD (mg / L) SS(mg / L) NH3-N(mg / L) TN (mg / L) TP (mg / L) Viscosity (mPa·S) 46800 34100 1840 3600 420 10

[0095] This embodiment adopts image 3 Process shown

[0096] (1) First pass the wastewater from the dairy farm through a 5-20mm grid / solid-liquid separator, and the liquid is transported to the anaerobic reactor through pipelines;

[0097] (2) Send the discharge inside the anaerobic reactor into a 50-200 mesh centrifugal solid-liquid separator to obtain separated solids and liquids, the solids are used as compost materials, and the liquids enter the subsequent treatment process;

[0098] (3) The hydraulic retention time of the anaerobic reactor is 25-35 days, and the temperature is maintained at 35-40°C;

[0099] The water quality of the anaerobic reactor effluent on May 21, 2021 is as follows:

[0100] COD (mg / L) S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com