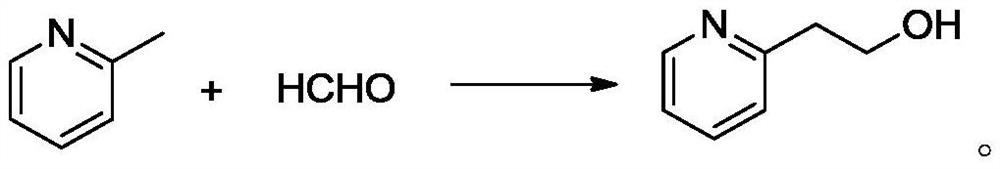

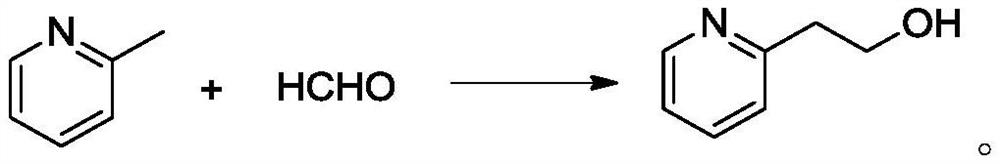

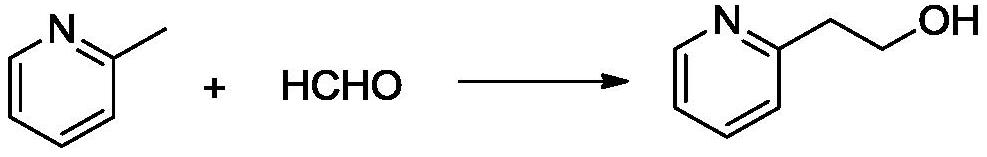

Synthesis method of (2-hydroxyethyl)pyridine

A technology of hydroxyethylpyridine and picoline, which is applied in the field of synthesis of 2-hydroxyethylpyridine, can solve the problems of high production cost, long reaction time, and low single-pass conversion rate, so as to shorten the reaction time and save production cost , The effect of high conversion rate in one pass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]

[0042] Add 2-picoline (30g, 322mmol), paraformaldehyde (2.04g, 64.4mmol, 95%), water (4.08g, 226mmol) and DABCO (0.36g, 3.22mmol) in the depolymerization flask at 120°C The depolymerization was carried out for 20 minutes, and it was used as the reaction solution to wait for the feed. Connect the stainless steel micro-reaction pipeline with the advection pump, and connect it with a pressure-adjustable backpressure valve, control the pipeline reaction pressure to 4MPa, and connect a 5m-long pre-cooling pipeline at the front end of the backpressure valve. Use reaction solvent water at a flow rate of 1 ml / min to fully rinse the 30-m-long reaction pipeline for 30 minutes, and then blow the reaction pipeline with nitrogen for 30 minutes to fully dry the pipeline. Control the temperature of the heater to 200° C., adjust the flow rate of the pump to 2 ml / min, and pump the reaction liquid to start the reaction. After 8min, the pale yellow liquid product begins to flow out,...

Embodiment 2

[0046] Add 2-picoline (30g, 322mmol), paraformaldehyde (2.04g, 64.4mmol, 95%), water (4.08g, 226mmol) and DABCO (0.36g, 3.22mmol) in the depolymerization flask at 120°C The depolymerization was carried out for 20 minutes, and it was used as the reaction solution to wait for the feed. Connect the stainless steel micro-reaction pipeline with the advection pump, and connect it with a pressure-adjustable backpressure valve, control the pipeline reaction pressure to 4MPa, and connect a 5m-long pre-cooling pipeline at the front end of the backpressure valve. Use reaction solvent water at a flow rate of 1 ml / min to fully rinse the 30-m-long reaction pipeline for 30 minutes, and then blow the reaction pipeline with nitrogen for 30 minutes to fully dry the pipeline. Control the temperature of the heater to 200°C, adjust the flow rate of the pump to 1ml / min, and pump the reaction solution to start the reaction. After 15min, the light yellow liquid product began to flow out, and the liq...

Embodiment 3

[0048] Add 2-picoline (30g, 322mmol), paraformaldehyde (2.04g, 64.4mmol, 95%), water (6.12g, 340mmol) and DABCO (0.36g, 3.22mmol) in the depolymerization flask at 120°C The depolymerization was carried out for 20 minutes, and it was used as the reaction solution to wait for the feed. Connect the stainless steel micro-reaction pipeline with the advection pump, and connect it with a pressure-adjustable backpressure valve, control the pipeline reaction pressure to 4MPa, and connect a 5m-long pre-cooling pipeline at the front end of the backpressure valve. Use reaction solvent water at a flow rate of 2 ml / min to fully rinse the 30-m-long reaction pipeline for 30 minutes, and then blow the reaction pipeline with nitrogen for 30 minutes to fully dry the pipeline. Control the temperature of the heater to 200° C., adjust the flow rate of the pump to 2 ml / min, and pump the reaction liquid to start the reaction. After 8min, the pale yellow liquid product begins to flow out, and the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com