Extraction method of biologically fermented carotenoid

A technology of carotenoids and extraction methods, applied in chemical instruments and methods, hydrocarbons, extraction purification/separation, etc., can solve the problems of reducing purity, increasing the difficulty of carotenoid extraction process, limiting extraction yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

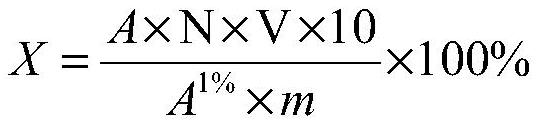

[0084] A method for extracting biologically fermented carotenoids, using Saccharomyces cerevisiae fermented liquid expressing lycopene as a raw material for extraction, specifically:

[0085] (1) Spray-dry the 20L lycopene fermented liquid after fermentation and putting it into the tank, set the inlet air temperature to 190°C, and the outlet air temperature to 90°C, spray dry to obtain 1kg of dry yeast powder;

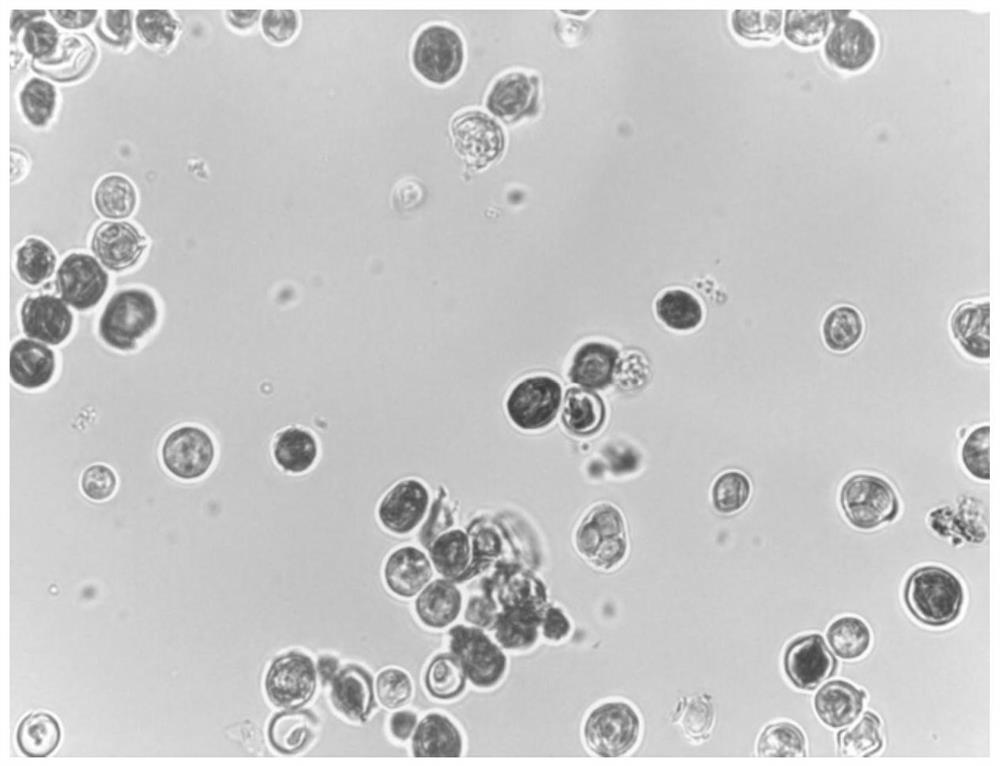

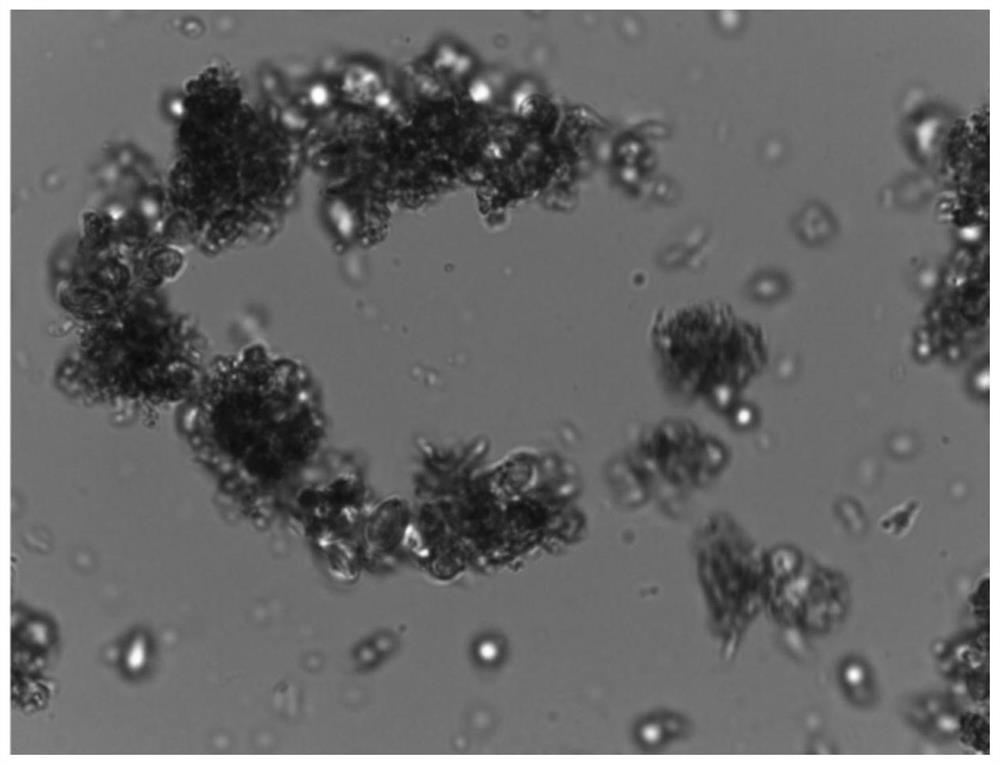

[0086] (2) The dry yeast powder is humidified with purified water and adjusted to a water content of 10%, and then the wall is broken by a low-temperature shearing machine for 30 minutes. The cooling form is closed circulating water cooling, and the temperature is 8°C. The wall-broken bacteria powder is collected, and the wall-breaking rate is greater than 98% after testing, and the loss of lycopene content is less than 2%;

[0087] (3) Add 10 L of ethanol solution with a sodium hydroxide content of 1% to the dried bacterial powder after the wall breaking for saponific...

Embodiment 2

[0093] A method for extracting biologically fermented carotenoids, using Saccharomyces cerevisiae fermented liquid expressing β-carotene as a raw material for extraction, specifically:

[0094] (1) Spray-dry the 22L beta-carotene fermented liquid after fermentation and putting into the tank, set the air inlet temperature to 180°C, and the air outlet temperature to 80°C, spray dry to obtain 1.32kg of dry yeast powder;

[0095](2) The dry yeast powder is humidified with purified water and adjusted to a water content of 10%, and then the wall is broken by a low-temperature shearing breaker for 45 minutes. The cooling form is closed circulating water cooling, and the temperature is 4°C. Collect the broken wall bacteria powder, the broken wall rate is more than 99% after testing, and the loss of β-carotene content is less than 1.5%;

[0096] (3) Add 6.6L of ethanol solution with a sodium hydroxide content of 2% to the dried bacteria powder after the wall breaking for saponification...

Embodiment 3

[0102] A method for extracting biologically fermented carotenoids, using astaxanthin-expressing Saccharomyces cerevisiae fermentation broth as raw material for extraction, specifically:

[0103] (1) Spray-dry the 25L astaxanthin fermented liquid after fermentation and putting it into the tank, set the air inlet temperature to 190°C, and the air outlet temperature to 90°C, and spray dry to obtain 1.4kg of dry yeast powder;

[0104] (2) The dry yeast powder is humidified with purified water and adjusted to a water content of 9%, and then the wall is broken by a low-temperature shearing breaker for 60 minutes. The cooling form is closed circulating water cooling, and the temperature is 0°C. The wall-broken bacteria powder is collected, and the wall-breaking rate is greater than 99% after testing, and the loss of astaxanthin content is less than 2.5%;

[0105] (3) Add 8.4L of ethanol solution with a sodium hydroxide content of 3% to the dried bacteria powder after the wall breakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com