Method for extracting cesium and rubidium from lepidolite

A technology of lepidolite and lepidolite powder, applied in the direction of improving process efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

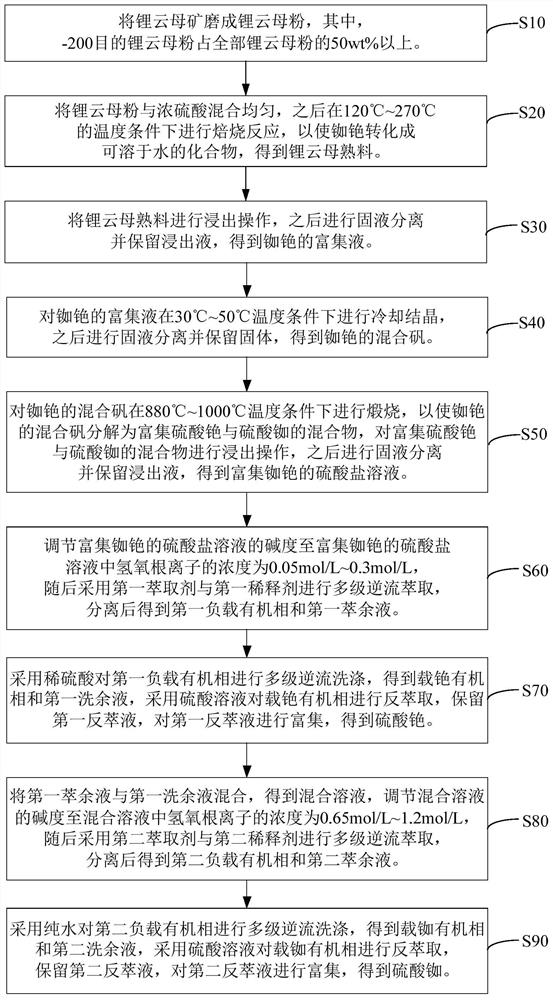

Image

Examples

Embodiment 1

[0077] The method for extracting cesium and rubidium from lepidolite is as follows:

[0078] 5000g of lepidolite ore was ground into lepidolite powder, wherein -200 mesh lepidolite powder accounted for 80wt% of all lepidolite powder.

[0079] Mix the lepidolite powder with 90% concentrated sulfuric acid, the mass ratio of the concentrated sulfuric acid to the lepidolite powder is 0.85, and then roast at 270° C. to obtain the lepidolite clinker.

[0080] The lepidolite clinker was stirred and leached with 20L of water at 80°C, followed by solid-liquid separation and the leaching solution was retained to obtain a rubidium and cesium enrichment solution. In the enrichment solution of rubidium and cesium, K 2 O, Rb 2 O and Cs 2 The leaching rate of O reaches 96%, 95% and 95% successively.

[0081] Lower the temperature of the enriched solution obtained from rubidium and cesium to 30°C for cold crystallization, then separate the solid from the liquid and retain the solid to obt...

Embodiment 2

[0089] The method for extracting cesium and rubidium from lepidolite is as follows:

[0090] 1000g of lepidolite ore was ground into lepidolite powder, wherein -200 mesh lepidolite powder accounted for 70wt% of all lepidolite powder.

[0091] Mix lepidolite powder with 70% concentrated sulfuric acid, the mass ratio of concentrated sulfuric acid to lepidolite powder is 1.7, then roast at 120°C to obtain lepidolite clinker.

[0092] The lepidolite clinker was stirred and leached with 5L of water at 95°C, followed by solid-liquid separation and the leaching solution was retained to obtain a rubidium and cesium enrichment solution. In the enrichment solution of rubidium and cesium, K 2 O, Rb 2 O and Cs 2 The leaching rate of O reaches 96%, 95% and 95% successively.

[0093] Lower the temperature of the enriched solution obtained from rubidium and cesium to 50°C for cold crystallization, then separate the solid from the liquid and retain the solid to obtain the mixed alum and c...

Embodiment 3

[0101] The method for extracting cesium and rubidium from lepidolite is as follows:

[0102] 50000g of lepidolite ore was ground into lepidolite powder, wherein -200 mesh lepidolite powder accounted for 60wt% of all lepidolite powder.

[0103] Mix lepidolite powder with 85% concentrated sulfuric acid, the mass ratio of concentrated sulfuric acid to lepidolite powder is 1.36, and then roast at 200°C to obtain lepidolite clinker.

[0104] The lepidolite clinker was stirred and leached with 200L of water at 85°C, followed by solid-liquid separation and the leaching solution was retained to obtain a rubidium and cesium enrichment solution. In the enrichment solution of rubidium and cesium, K 2 O, Rb 2 O and Cs 2 The leaching rate of O reaches 96%, 95% and 95% successively.

[0105] Lower the temperature of the enriched solution obtained from rubidium and cesium to 35°C for cold crystallization, then separate the solid from the liquid and retain the solid to obtain the mixed al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com