Organic electroluminescence device and preparation method thereof

An electroluminescent device and electroluminescent technology, applied in the directions of organic light-emitting devices, organic light-emitting device structures, organic semiconductor devices, etc., can solve the damage of organic functional layers, poor film formation of lithium fluoride, and reduce the probability of electron and hole recombination And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

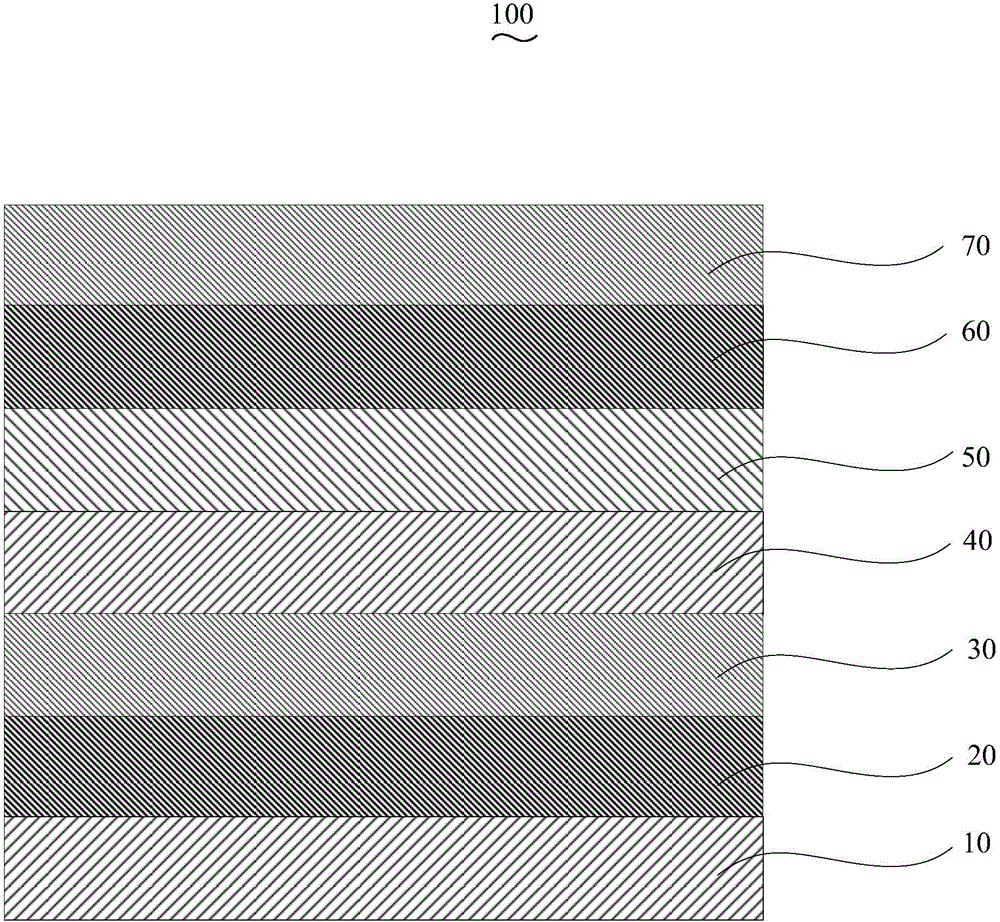

[0034] The preparation method of the organic electroluminescent device 100 according to an embodiment includes the following steps:

[0035] In step S110 , a hole injection layer 20 , a hole transport layer 30 , a light emitting layer 40 , an electron transport layer 50 and an electron injection layer 60 are sequentially formed on the surface of the anode 10 .

[0036]The anode 10 is indium tin oxide glass (ITO), fluorine-doped tin oxide glass (FTO), aluminum-doped zinc oxide glass (AZO) or indium-doped zinc oxide glass (IZO), preferably ITO, the thickness of the anode 10 It is 50 nm to 300 nm, preferably 140 nm.

[0037] In this embodiment, before the hole injection layer 20 is formed on the surface of the anode 10, the anode 10 is pre-treated. The pre-treatment includes: subjecting the anode 10 to photolithography, cutting it into a required size, using detergent, deionization Water, acetone, ethanol, and isoacetone were each ultrasonically cleaned for 15 minutes to remove ...

Embodiment 1

[0052] The structure prepared in this example is ITO / MoO 3 / NPB / Alq 3 / Bphen / Rb 2 CO 3 :MoO 3 : Zn / Ag organic electroluminescence device, in this embodiment and the following embodiments, " / " indicates layer, ":" indicates doping.

[0053] First, the ITO is subjected to photolithography, and then cut into the required size, and then ultrasonicated with detergent, deionized water, acetone, ethanol, and isopropanol for 15 minutes each to remove organic pollutants on the glass surface; after cleaning, the conductive substrate is cleaned. Appropriate treatment: oxygen plasma treatment, treatment time is 5min, power is 30W; thickness is 130nm, hole injection layer is evaporated, and the material is MoO 3 , the thickness is 40nm; the vapor-deposited hole transport layer is made of NPB and the thickness is 30nm; the vapor-deposited light-emitting layer is made of Alq 3 , the thickness is 17nm; the electron transport layer is evaporated, the material is Bphen, the thickness is 16...

Embodiment 2

[0060] The structure prepared in this example is AZO / V 2 O 5 / NPB / DCJTB / Bphen / RbCl:WO 3 : Zn / Al organic electroluminescent devices.

[0061] First, the AZO glass substrate was washed with detergent, deionized water, and ultrasonic for 15 minutes to remove organic pollutants on the surface of the glass; vapor deposition hole injection layer: the material is V 2 O 5 , the thickness is 40nm; the vapor-deposited hole transport layer: the material is NPB, the thickness is 45nm; the vapor-deposited light-emitting layer: the selected material is DCJTB, the thickness is 8nm; the vapor-deposited electron transport layer, the material is TAZ, the thickness is 65nm; Electron beam evaporation electron injection layer, the material is RbCl:WO 3 : Zn, RbCl, WO 3 The mass ratio with Zn is 2:1:1, the thickness is 100nm, and the thickness is 100nm. The material is Al, and the thickness is 80nm.

[0062] The specific process conditions of the electron beam evaporation method are: the worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com