Injection module for reducing agent

A technology of injection module and reducing agent, which is applied in exhaust gas treatment, mechanical equipment, engine components, etc., can solve the problems of inability to generate large penetration depth, narrow spray cone, and release, etc., and achieve high injection speed and low cost. , the effect of uniform preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

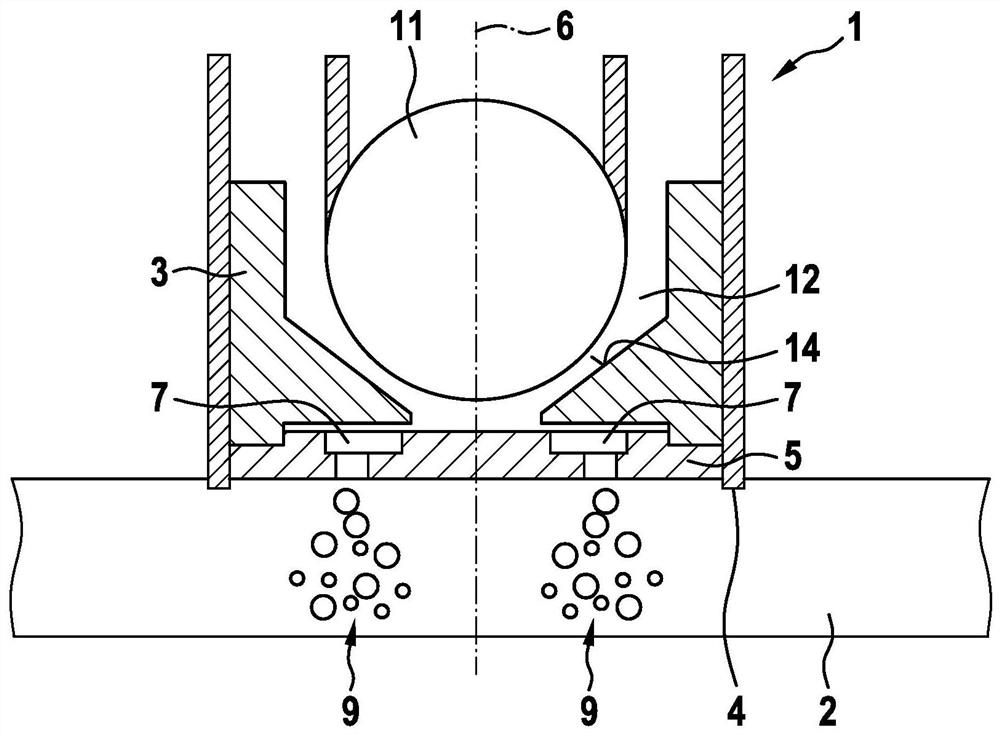

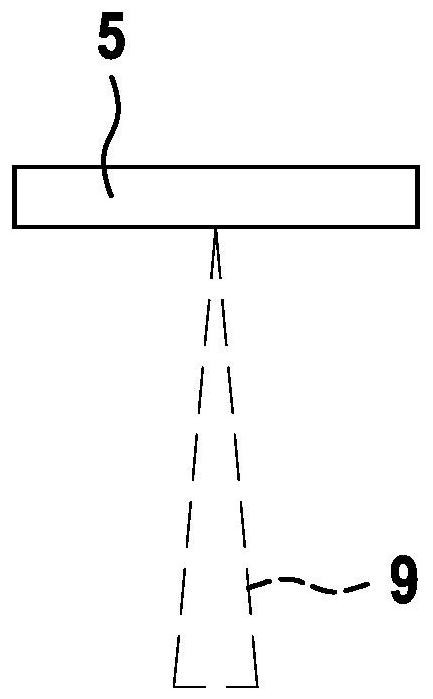

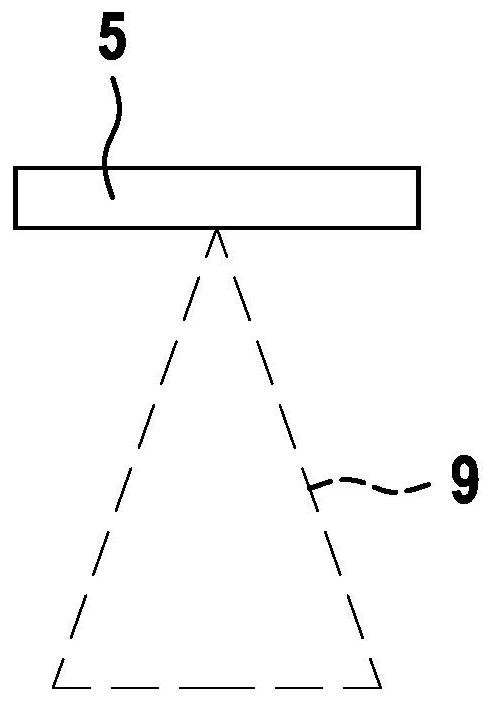

[0021] exist figure 1 shows an injection module, as it is used to introduce reducing agent into the exhaust system of an internal combustion engine. The injection module 1 has a housing 3 which engages in an opening 4 in the wall of the exhaust system 2 . The housing 3 has a reducing agent chamber 12 in which reducing agent is kept under injection pressure. Furthermore, a valve element 11 is arranged longitudinally displaceable in the reducing agent chamber 12 , which here is spherical in shape and cooperates with a valve seat 14 for opening and closing the flow cross section. The housing 3 is delimited at its end facing the exhaust system 2 by an injection disk 5 . The injection disk 5 is designed as a circular or rectangular plate and has two injection openings 7 which are formed in the injection disk 5 opposite to each other with respect to the longitudinal axis 6 of the injection module 1 . If the valve element 11 is moved away from the valve seat 14 by a mechanism, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com