Method for measuring uniformity of nanocrystalline hard alloy

A technology of hard alloy and measurement method, which is applied in the direction of measuring device, test sample preparation, instrument, etc., can solve the problems of difficult popularization and application, complicated sample preparation steps, high capital investment, etc., and achieve easy focusing, difficult focusing, difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

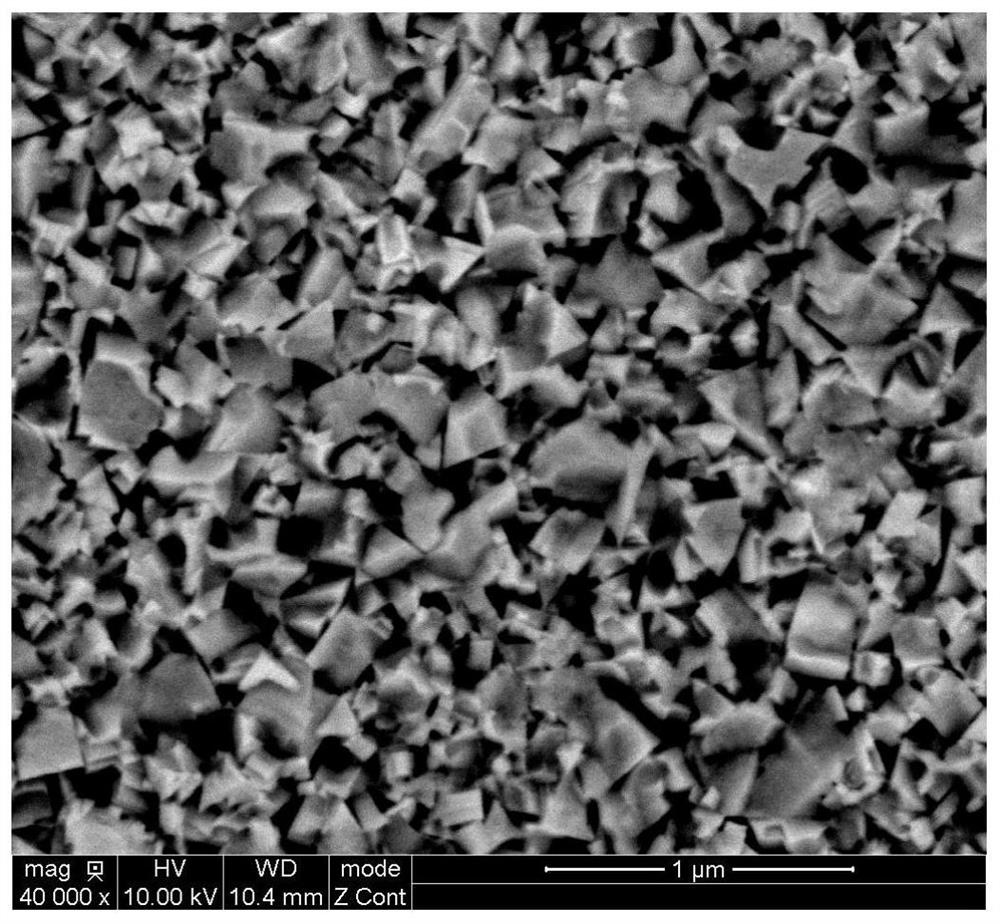

[0031] The measurement of the uniformity of WC / Co cemented carbide with Co as the binder phase is as follows:

[0032] S1. Sample preparation. Including mirror polishing and metallographic etching, where:

[0033] (1), mirror polishing: the specific operation is (1) sample pre-grinding: use a 75-micron diamond magnetic grinding disc, continue to flow water for grinding, and the grinding and polishing time is 2-6min; (2) sample coarse grinding: use 18 micron The diamond magnetic grinding disc is continuously flowing out of water for grinding, and the grinding and polishing time is 2-3 minutes; (3) Sample fine grinding: a 10-micron magnetic grinding disc is used, continuously flowing out of water for grinding, and the grinding and polishing time is 2-3 minutes; (4) Coarse Polishing: Use nylon polishing cloth to add 9-micron diamond suspension for automatic grinding, and the polishing time is 2-3 minutes; (5) Fine polishing: Use nylon polishing cloth for automatic grinding with ...

Embodiment 2

[0042] Measurement of homogeneity of cemented carbides with cubic carbides as inhibitors.

[0043] The measurement steps are the same as in Example 1.

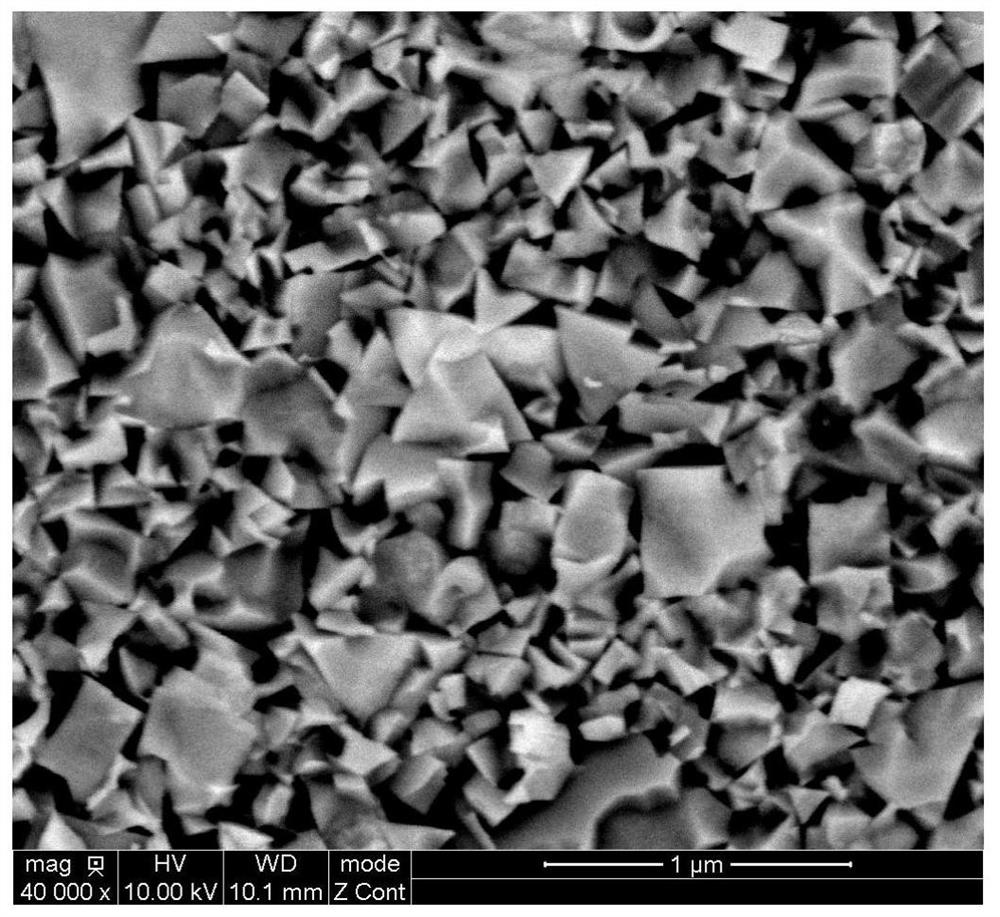

[0044] Wherein the microstructure photograph that S2 observation step obtains sees attached figure 2 . From attached figure 2 It can be seen that the cemented carbide grains with cubic carbides as inhibitors are uniform and dense, and the average grain length is 0.30 μm. The use of field emission scanning electron microscopy (FESEM) can significantly improve the image resolution and achieve the purpose of simple and rapid measurement of the uniformity of nanocrystalline cemented carbide.

Embodiment 3

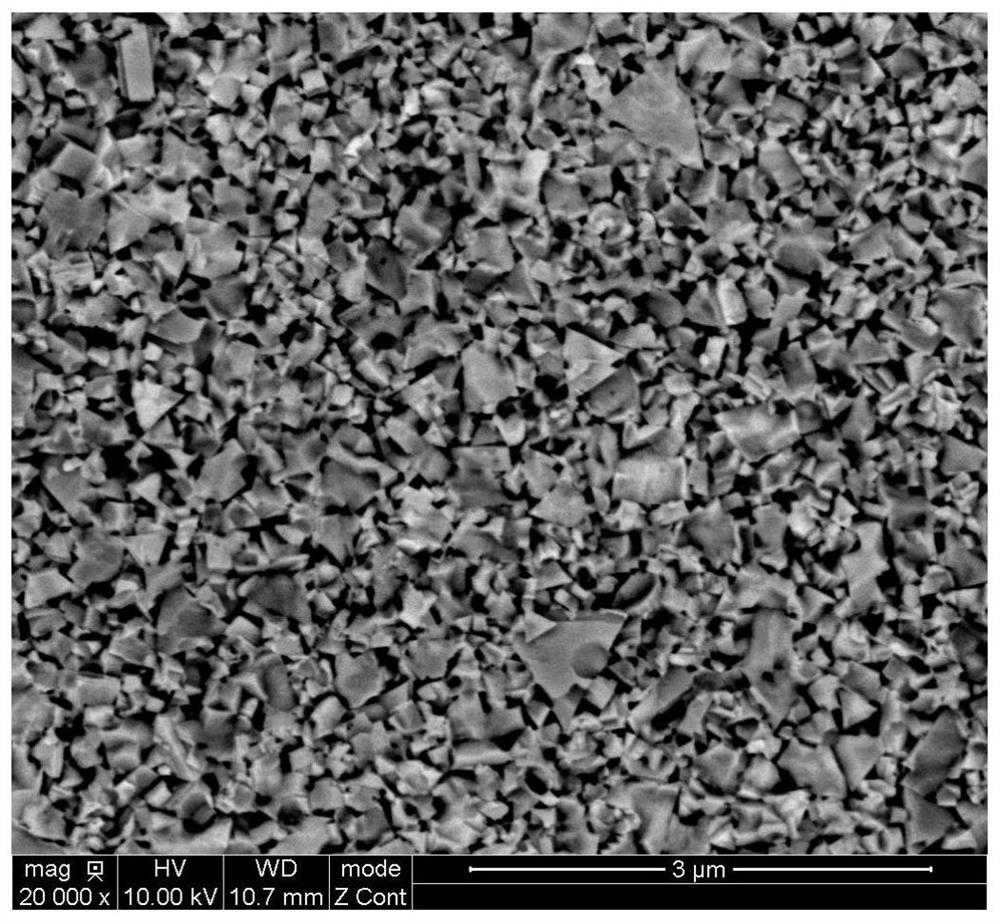

[0046] Measurement of homogeneity of cemented carbide with TiC as inhibitor.

[0047] The measurement steps are the same as in Example 1.

[0048] Among them, the photographing in the S2 observation step is set to 20,000 times, and the microstructure photos obtained are shown in the attached image 3 . From attached image 3 It can be seen that the cemented carbide grains with TiC as the inhibitor are uniform and dense, and the average grain length is 0.30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com