Construction load detection method and system for aluminum alloy formwork assembling system

An aluminum alloy formwork and assembly system technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve obstacles to the promotion of new formwork, less research on construction load detection technology, and inability to accurately grasp the quality of construction entities in real time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

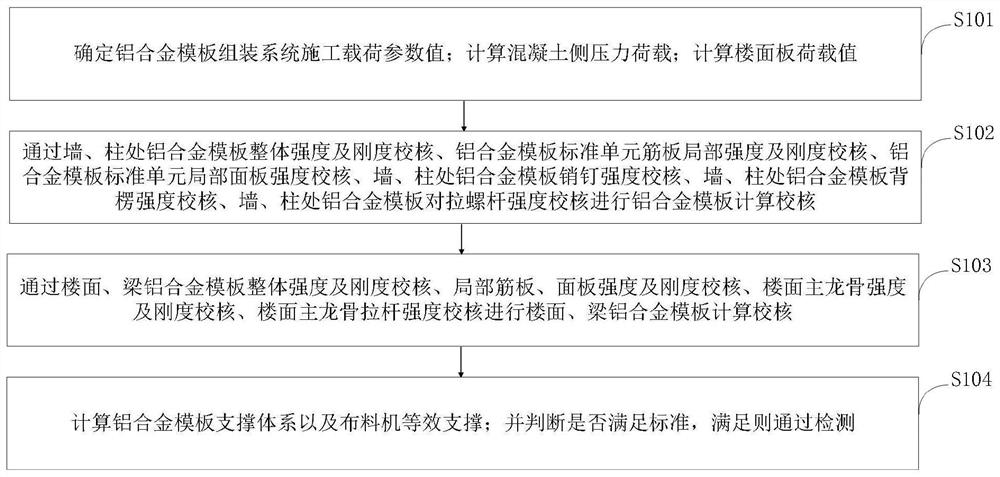

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0238] 1. Construction load of aluminum alloy formwork system

[0239] 1.1. Construction load value

[0240] Concrete structure loads are taken in accordance with GB50666-2011 "Code for Construction of Concrete Structure Engineering".

[0241] 1. Standard value of self-weight of aluminum formwork: 0.25KN / ㎡

[0242] 2. Concrete weight density: 24KN / m 3

[0243] 3. The standard value of self-weight of steel bar is 1.1KN / m 3

[0244] 4. Standard value of construction live load: 2.5KN / ㎡

[0245] The concrete pouring speed is 1.8m / h; the concrete slump is 160mm~180mm; the concrete construction temperature is 25°C; and a water reducing agent is added during concrete construction.

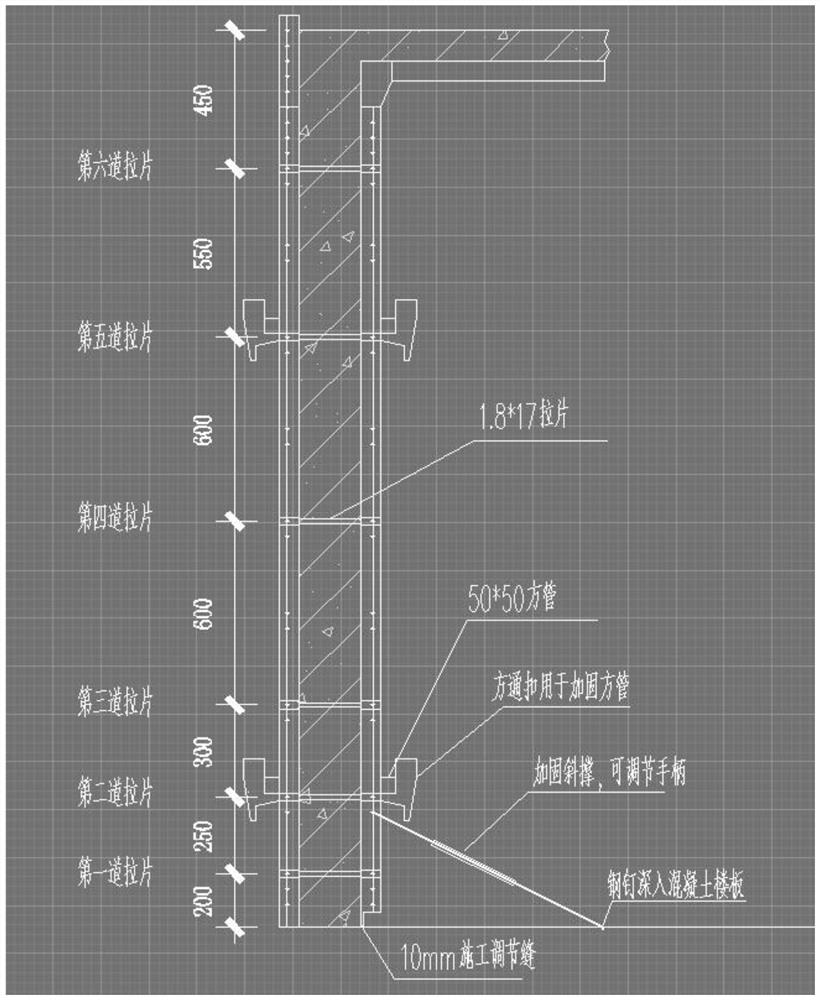

[0246] The standard floor height of the embodiment of the present invention is 2900mm, and the maximum plate thickness is 150mm.

[0247] 1.2 Concrete lateral pressure load

[0248] Concrete lateral pressure is calculated according to the following formula according to the latest version of "Code ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com