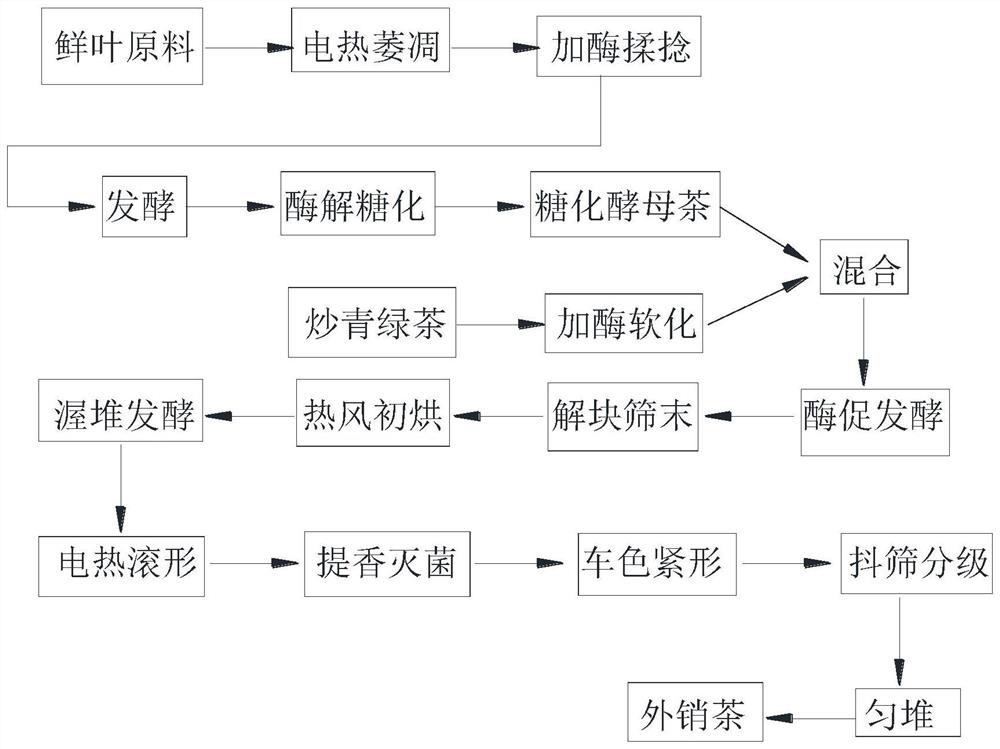

Process method for preparing export tea by using exogenous enzymes

A process method and technology of exogenous enzymes, which are applied in the field of using exogenous enzymes to prepare tea for export, can solve the problems of unstable blending quality and poor taste of green tea and black tea, so as to increase the content of water extracts and make the soup color bright yellow and red , The effect of dark brown and oily color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: utilize spring tealeaves to prepare the processing method of export tea, comprise the following steps:

[0033] One: First use spring tea to prepare saccharified yeast tea, the specific method is as follows:

[0034] S1: fresh leaf raw materials, plucking 3-4 leaves of a bud and the middle and low-grade tea tree fresh leaf raw materials;

[0035] S2: Electric heating withering, input the picked fresh leaf raw materials into the electric heating withering machine for withering, set the hot air temperature of the electric heating withering machine to 39-40°C, the air volume to 3-3.5 cubic meters per second, and the withering time to 5.5-6h. Hot air withering emits "grass gas", which promotes water loss and reddening of buds and leaves, so that the water loss rate of buds and leaves after withering reaches 43-45%, and the rate of redness reaches 45%-48%; the electric heating withering machine is preferred But not limited to YF-6CWD-30 black tea withering mac...

Embodiment 2

[0053] Embodiment 2: utilize summer tealeaves to prepare the processing method of export tea, comprise the following steps:

[0054] One: First use spring tea to prepare saccharified yeast tea, the specific method is as follows:

[0055] S1: fresh leaf raw materials, plucking 3-4 leaves of a bud and the middle and low-grade tea tree fresh leaf raw materials;

[0056] S2: Electric heating withering, the picked fresh leaf raw materials are input into the electric heating withering machine for withering, the hot air temperature of the electric heating withering machine is set to 38-39°C, the air volume is 3.5-4 cubic meters per second, and the withering time is 5-5.3h. The "grass gas" is emitted by hot air withering, which promotes the dehydration, withering and reddening of buds and leaves, so that the dehydration rate of buds and leaves after withering reaches 40-42%, and the reddening rate reaches 45%-48%;

[0057] S3: Knead with enzyme, add 0.15-0.18% by weight to the buds and...

Embodiment 3

[0073] Embodiment 3: utilize autumn tealeaves to prepare the processing method of export tea, comprise the following steps:

[0074] One: First use spring tea to prepare saccharified yeast tea, the specific method is as follows:

[0075] S1: fresh leaf raw materials, plucking 3-4 leaves of a bud and the middle and low-grade tea tree fresh leaf raw materials;

[0076] S2: Electric heating withering, the picked fresh leaf raw materials are input into the electric heating withering machine for withering, the hot air temperature of the electric heating withering machine is set to 38-39°C, the air volume is 3.9-4 cubic meters per second, and the withering time is 5-5.2h. The "green grass gas" is emitted by hot air withering, which promotes the dehydration, withering and reddening of buds and leaves, so that the dehydration rate of buds and leaves after withering reaches 40-43%, and the reddening rate reaches 45%-48%;

[0077] S3: Knead with enzyme, add 0.18-0.2% by weight to the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Diagonal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com