A kind of photosensitizer and its use and preparation method

A technology of photosensitizer and photosensitization, which is applied in the field of materials, can solve the problem that the efficiency of photosensitizer is not too high, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] Further, the present invention also proposes a preparation method of a photosensitizer, comprising the following steps:

[0059] Step S1, the first reaction raw material and containing R 1 Mix the raw materials for the second reaction, and heat them together to 60°C-100°C, then continuously illuminate for 18h-30h while maintaining the temperature, then cool, separate, and purify to obtain an intermediate product;

[0060] Wherein, the chemical structural formula of the first reaction raw material is:

[0061]

[0062] R 1 Any of the following groups can be used:

[0063]

[0064] Wherein, n is 1, 2, 3, 4, 5, 6 or 7;

[0065] Step S2, the intermediate product and containing R 2 The third reaction raw material reacts, thereby obtains photosensitizer.

[0066] Among them, R 2 Any of the following groups can be used:

[0067]

[0068] Furthermore, in the above technical solution, the first reaction raw material and the second reaction raw material are usuall...

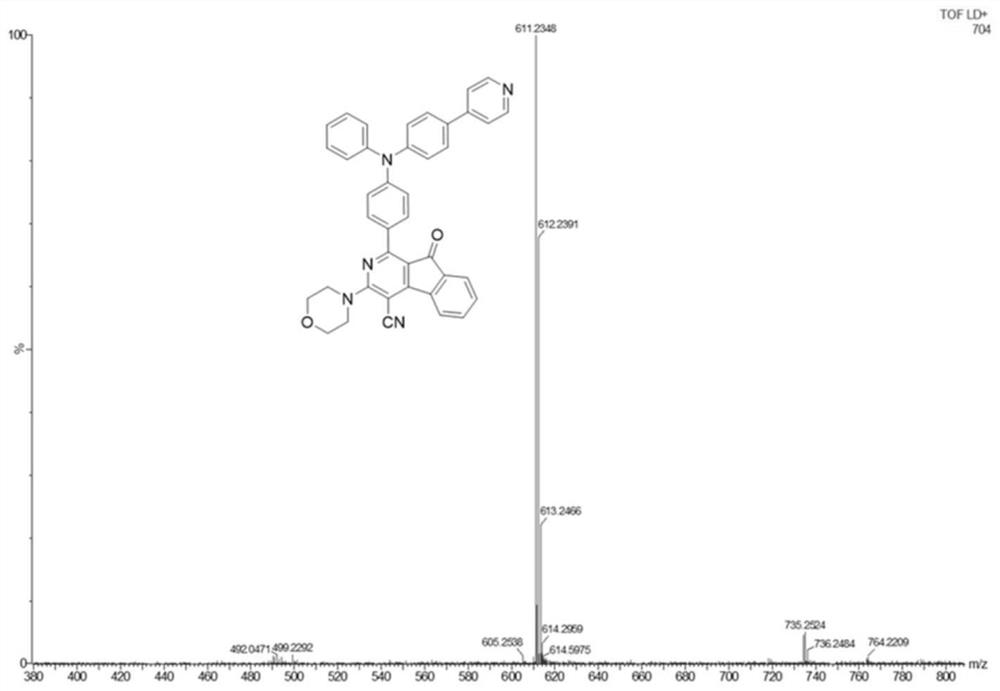

no. 1 example

[0073] In this embodiment, the chemical structural formula of the photosensitizing molecule is:

[0074]

[0075] This embodiment also proposes a preparation method for the above-mentioned photosensitizing molecule, comprising the following steps:

[0076] 1) Synthesis of TPABr

[0077]

[0078] BDOYM-Br (0.5 g, 0.95 mmol), morpholine (0.082 g, 0.95 mmol) and acetonitrile (MeCN) (20 mL) were mixed in a two-neck round bottom flask, then heated together to 80 °C with stirring under dry air , and continuously irradiated with a 7W fluorescent LED bulb for 24h; after the reaction was completed, cooled to room temperature, and the solvent was distilled off under reduced pressure. The mixed product was further separated and purified by silica gel column chromatography to obtain the target product (0.35 g, yield 60%), namely TPABr, as an orange-red solid. 1 H NMR(d-DMSO,400MHz):δ8.25(d,1H),7.85(d,2H),7.77-7.73(m,1H),7.66-7.62(m,2H),7.53(d,2H) ,7.41-7.37(t,2H),7.20-7.13(m,3H),...

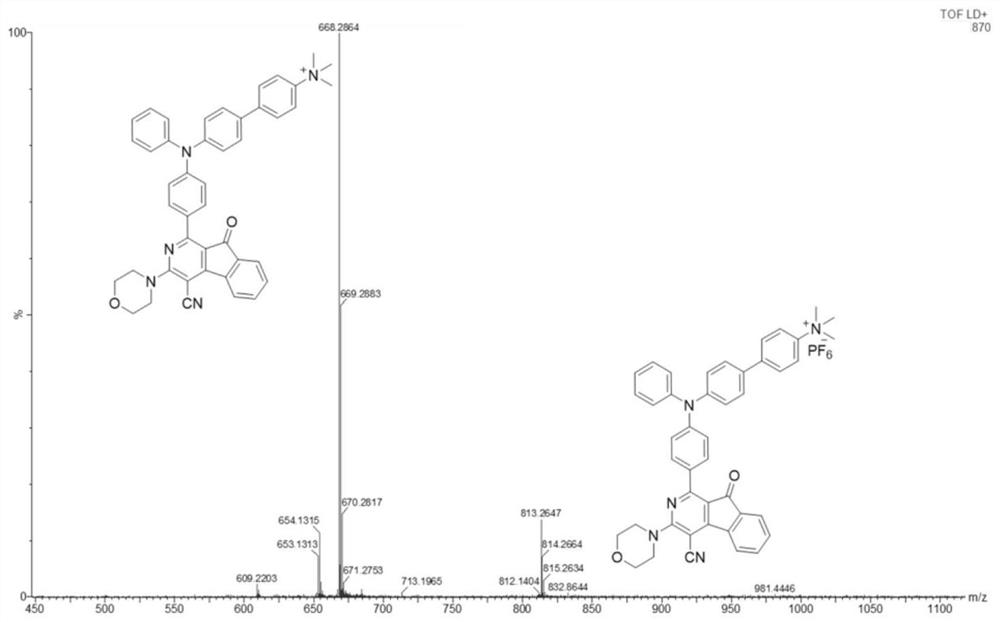

no. 2 example

[0083] In this embodiment, the chemical structural formula of the photosensitizing molecule is:

[0084]

[0085] This embodiment also proposes a preparation method for the above-mentioned photosensitizing molecule, comprising the following steps:

[0086]

[0087] TPAN (0.2 g, 0.31 mmol) and acetonitrile (5 mL) were mixed in a round bottom flask under nitrogen; additional methyl iodide (1 mL) was added and heated together at reflux for 12 h. After the reaction was completed, it was cooled to room temperature and poured into ether to obtain the first precipitate. Redissolve the first precipitate with acetone, add saturated potassium hexafluorophosphate (KPF 6 ) solution (5 mL) to give a mixture. The mixture was stirred at room temperature for 2 h. After the reaction was complete, acetone was evaporated under reduced pressure, and the second precipitate was filtered off, then washed with water and ether. Dry under reduced pressure to obtain product (0.15g, productive r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com