A kind of flexible solid-state lithium ion conductor applied to battery and preparation method thereof

An ionic conductor and solid lithium technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low conductivity, achieve the effect of improving exercise ability and ensuring transmission ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) The polymer adopts monooxalate borate-grafted polyvinyl formal, and the structural formula is as follows, wherein the lower x:y=4. 0.4305 g of the above polymer was weighed and dissolved in 2.583 g of dimethyl sulfoxide, and fully stirred to dissolve it completely.

[0026]

[0027] (2) Continue to add 0.031g of boron-containing organic lithium salt LiODFB (relative molecular mass 144), corresponding to the general structure R1 The molar ratio of the (1,3-dioxane) to the lithium ion of the organic lithium salt LiODFB is 15:1 to form a solution.

[0028] (3) The solution was then heated to 70°C and stirred for 24h to obtain a slurry, which was then uniformly coated on a glass plate and vacuum-dried at 50°C for 24h to obtain a flexible solid-state lithium ion conductor.

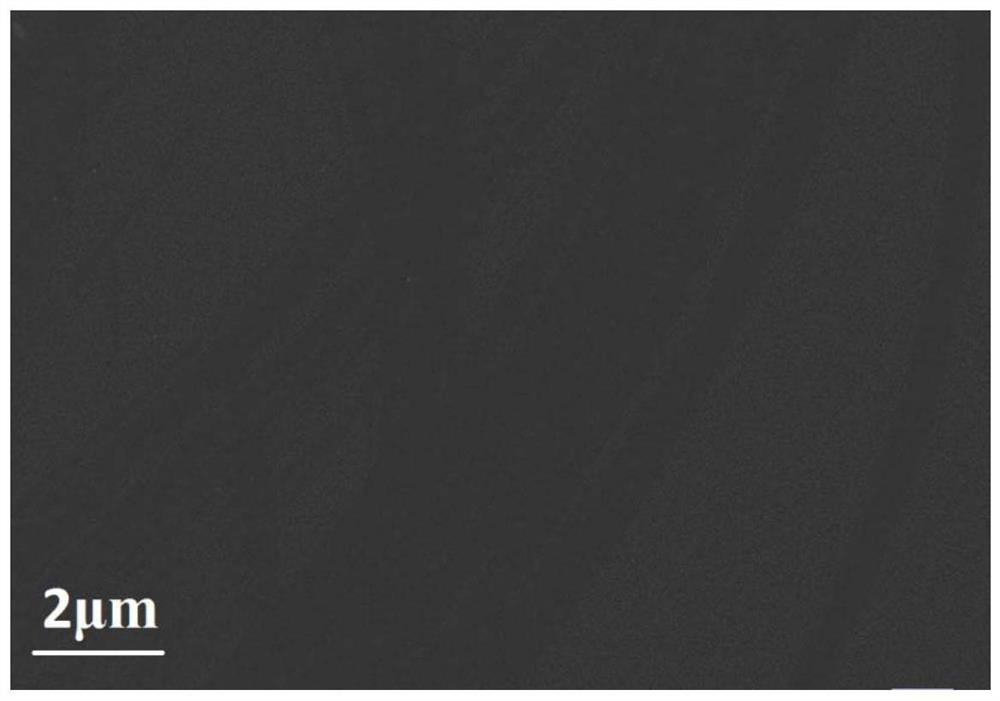

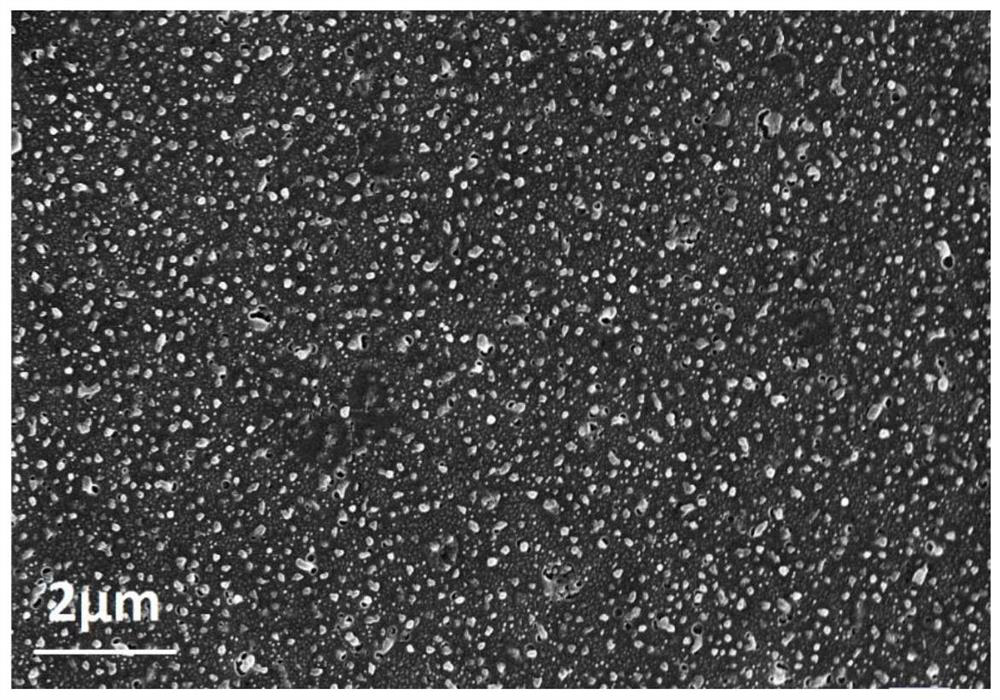

[0029] The microscopic morphology of the flexible solid-state lithium ion conductor obtained in Example 1 is as follows: figure 1 As shown in the figure, it can be seen that the lithium ion condu...

Embodiment 2

[0037] (1) The polymer adopts lithium benzenesulfonate grafted polyvinylidene fluoride, and the structural formula is as follows, wherein x: y= 1.2:1. Dissolve 0.7231 g of the above polymer in 3.32 g of acetonitrile, stir well to dissolve it completely.

[0038]

[0039] (2) Continue to add 0.054g organic lithium salt LiBETI with sulfonimide group (relative molecular mass 387), corresponding to the general structure R 1 the (-ch 2 -CF 2 -) with a molar ratio of 50:1 to the organic lithium salt LiBETI lithium ions to form a solution.

[0040] (3) Then the solution was heated to 40°C and stirred for 30h to obtain a slurry. Finally, the slurry was vacuum-dried at 60 °C for 36 h to obtain a flexible solid-state lithium ion conductor.

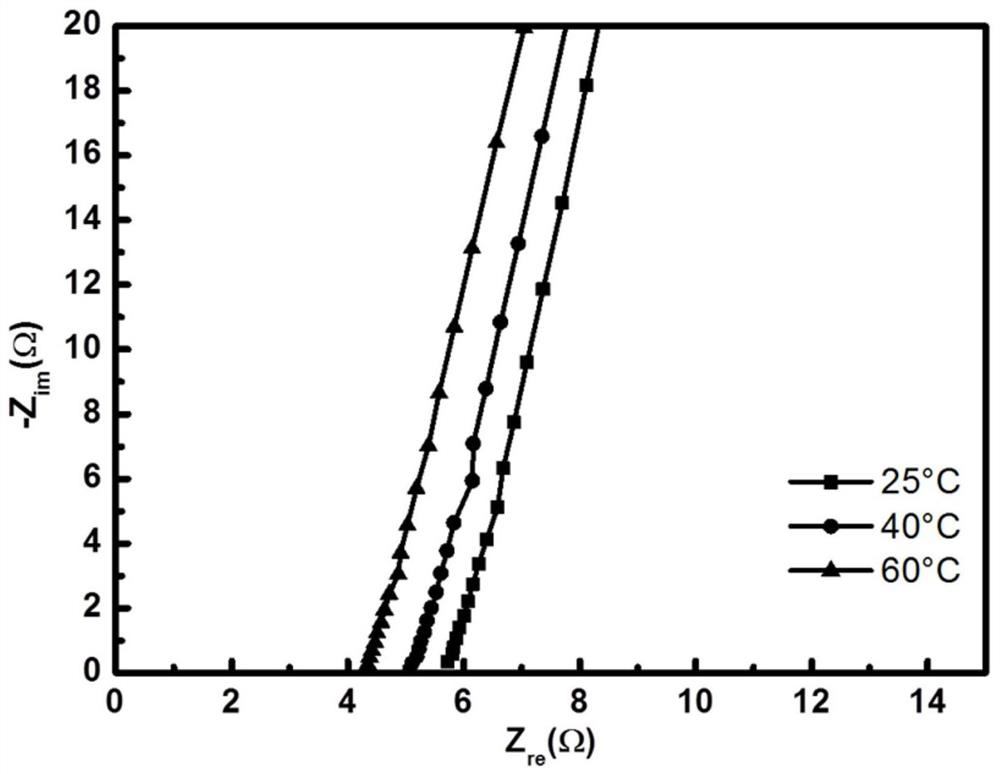

[0041] The AC impedance test results of the flexible solid-state lithium ion conductor obtained in Example 2 are as follows: image 3 As shown, at room temperature of 25 °C, the room temperature conductivity of this lithium ion conductor is ...

Embodiment 3

[0048] (1) The polymer adopts perfluoroalkyl carboxyl lithium grafted polyethylene carbonate, and the structural formula is shown below, wherein x:y=2.4:1. 0.6471 g of the above polymer was weighed and dissolved in 2.983 g of tetrahydrofuran, and fully stirred to dissolve it completely.

[0049]

[0050] (2) Continue to add 0.151g of organic lithium salt ddCTP-Li containing phosphoric acid groups 3 (relative molecular mass 469), corresponding to general structure R 1 The (-O-CO-O-CH 2 -) with the organolithium salt ddCTP-Li 3 The molar ratio of lithium ions is 10:1 to form a solution.

[0051] (3) Then the solution was heated to 120 °C and stirred for 2 h to obtain a slurry, which was then uniformly coated on a glass plate, and finally vacuum-dried at 60 °C for 36 h to obtain a flexible solid-state lithium ion conductor.

[0052] The solid lithium ion conductor obtained in Example 3 has good flexibility; the tensile strength-strain curve is as follows: Figure 7 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com