Preparation method of corrosion-resistant austenitic stainless steel

An austenitic stainless steel, corrosion-resistant technology, applied in the metallurgical field, can solve the problems of easy corrosion, chloride stress corrosion resistance, weak chemical corrosion ability, etc., achieve uniform composition, good mechanical properties, improved strength and chloride resistance. Effect of Corrosive Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056]A method for preparing corrosion-resistant austenitic stainless steel, the method comprising:

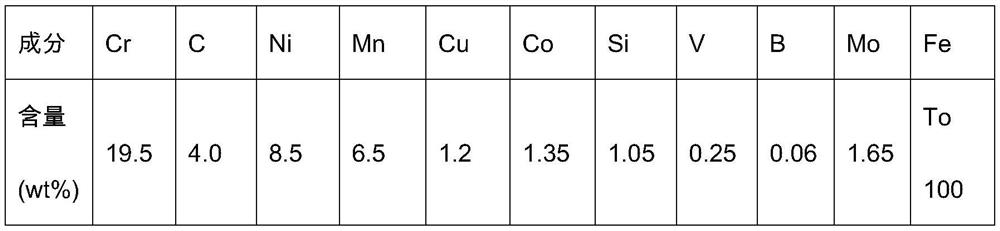

[0057]1) Use alloy or simple metal as raw materials to prepare molten steel. The composition of molten steel is shown in Table 1 below:

[0058]Table 1: Composition table of molten steel

[0059]

[0060]Fe in the table represents iron element and inevitable impurities;

[0061]2) Add Q195 low carbon steel by feeding silicon-calcium wire. The addition amount of low carbon steel is 0.55kg / t molten steel, and then continuous casting is carried out. The continuous casting tundish adopts the tundish liquid level to ensure that the liquid level is 460~470mm. Continuous casting billet

[0062]3) Preheat the continuous casting billet. During the preheating process, the temperature is raised to 380°C at a rate of 5°C / min, then to 680°C at a rate of 15°C / min, and then to 760°C at a rate of 5°C / min, and the temperature is kept for 20 minutes. , 830℃ hot-rolled into a steel coil with a thickness of 2.8mm and a ...

Embodiment 2

[0064]A method for preparing corrosion-resistant austenitic stainless steel, the method comprising:

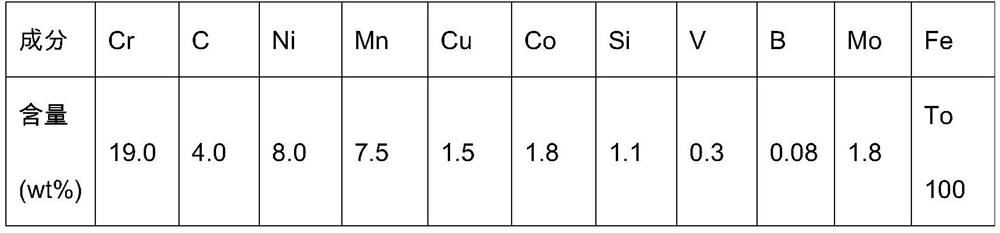

[0065]1) Use alloy or simple metal as raw materials to prepare molten steel. The composition of molten steel is shown in Table 2 below:

[0066]Table 2: Composition table of molten steel

[0067]

[0068]Fe in the table represents iron element and inevitable impurities;

[0069]2) Add Q195 low carbon steel by feeding silicon calcium wire. The addition amount of low carbon steel is 0.6kg / t molten steel, and then continuous casting is carried out. The continuous casting tundish adopts the tundish liquid level to ensure that the liquid level is 460~470mm. Continuous casting billet

[0070]3) Preheat the continuous casting billet. In the preheating process, the temperature is increased to 380°C at a rate of 10°C / min, then to 680°C at a rate of 20°C / min, and then to 780°C at a rate of 10°C / min, and the temperature is kept for 20 minutes. , 850℃ hot-rolled into a steel coil with a thickness of 2.8mm and a ...

Embodiment 3

[0072]A method for preparing corrosion-resistant austenitic stainless steel, the method comprising:

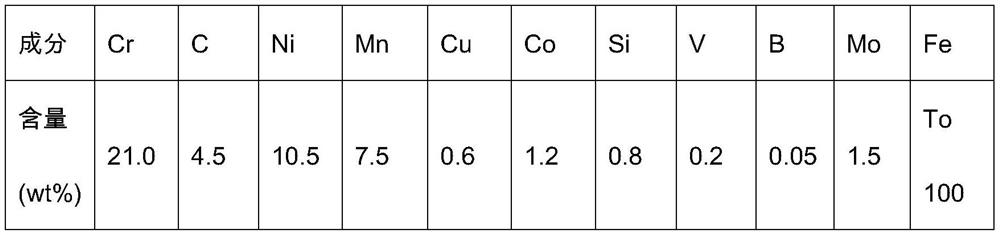

[0073]1) Use alloy or simple metal as raw materials to prepare molten steel. The composition of molten steel is shown in Table 3 below:

[0074]Table 3: Composition table of molten steel

[0075]

[0076]Fe in the table represents iron element and inevitable impurities;

[0077]2) Add Q195 low carbon steel by feeding silicon-calcium wire. The adding amount of low carbon steel is 0.5kg / t molten steel, and then continuous casting is carried out. The continuous casting tundish adopts the tundish liquid level to ensure that the liquid level is 460~470mm. Continuous casting billet

[0078]3) Preheat the continuous casting billet. During the preheating process, the temperature is raised to 380°C at a rate of 5°C / min, then to 680°C at a rate of 20°C / min, and then to 760°C at 8°C / min, and the temperature is kept for 15 minutes. , 820℃ hot-rolled into a steel coil with a thickness of 2.8mm and a width of 1100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com