Demolition-free formwork for construction and manufacturing method thereof

A technology without dismantling formwork and manufacturing method, which is applied in building structure, on-site preparation of building components, construction, etc., can solve the problems of easy damage of thermal insulation layer, inability to bear load, low structural strength, etc., so as to improve structural strength and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0049] As a specific embodiment of the method for manufacturing a non-demolition formwork for buildings provided by the present invention, the mortar includes the following components: 70-100 parts of cement, 80-120 parts of silica sand, and 98-150 parts of water. The above-mentioned parts are parts by mass, that is, the quality of 1 part of cement, 1 part of silica sand and 1 part of water is the same.

[0050] As a specific embodiment of the method for manufacturing a non-demolition formwork for buildings provided by the present invention, the thickness of the mortar is 5-20 mm.

[0051] As a specific embodiment of the method for manufacturing a non-demolition formwork for buildings provided by the present invention, the alkali-resistant tensile breaking strength of the glass fiber mesh cloth is ≥750N / 50mm (warp direction, weft direction).

Embodiment 1

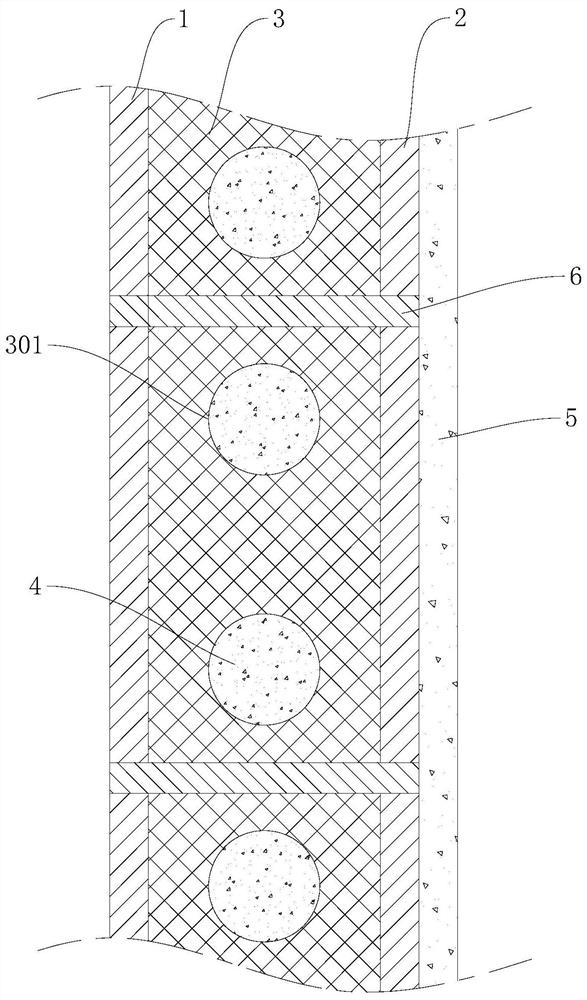

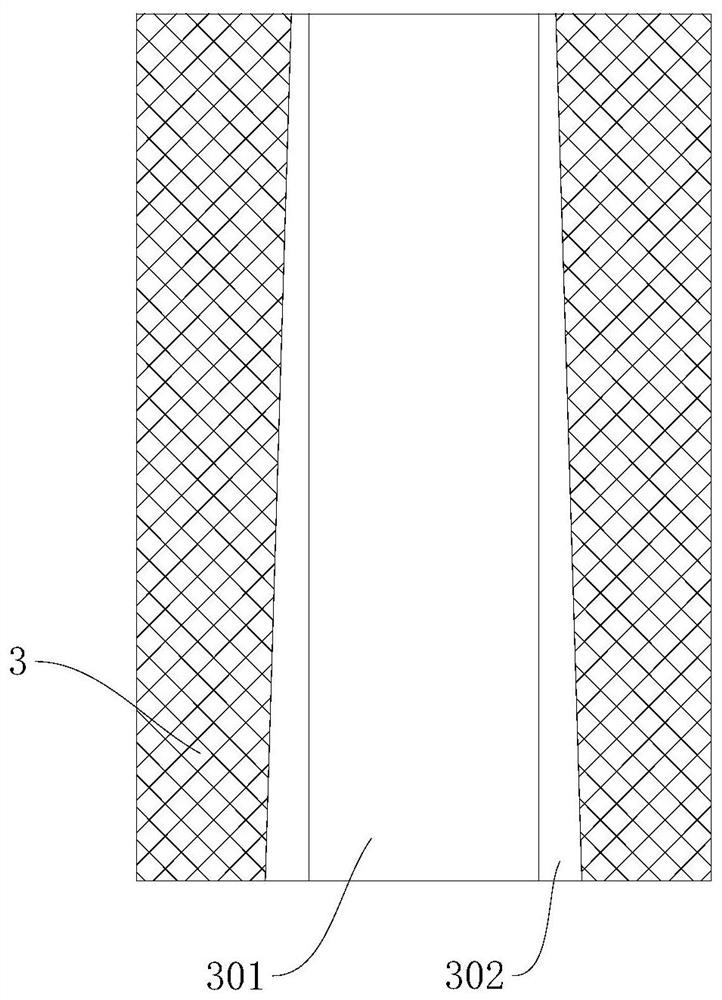

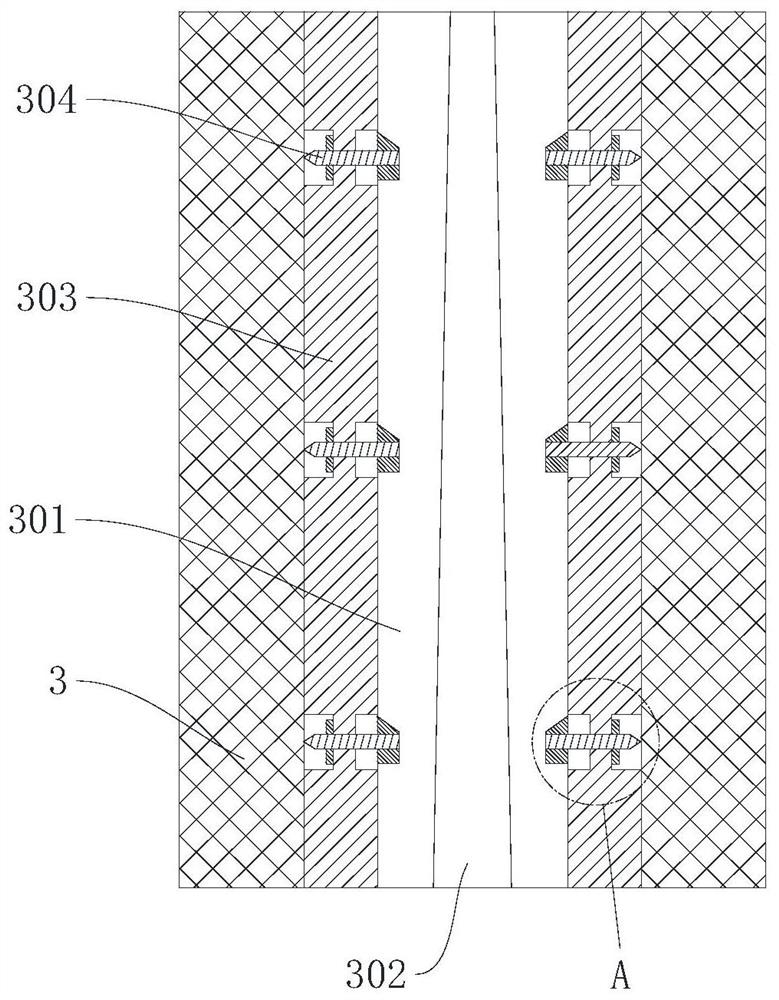

[0053] In this embodiment, the overall size of the inner steel wire mesh 1 and the outer layer steel wire mesh 2 is 0.1m 2 , the overall size is 0.33m*0.33m, the diameter of the steel wire is 2mm, and the size of the square hole is 400mm 2 ; The distance between the inner steel wire mesh 1 and the outer layer steel wire mesh 2 is 20mm.

[0054] In this embodiment, the thermal insulation core layer 3 is made of ceramic wool board, the ceramic wool board is a board made of aluminum silicate ceramic fiber, its thermal conductivity is 0.03W / (m·k), and its combustion performance level is A1 ( GB8624-2012). The thickness of the ceramic wool board is 20mm, the overall size is cut to 0.35m*0.35m, and the interface width (the size of the insulation core layer 3 protruding from the inner and outer steel mesh layers) is 0.02m. The cement column 4 is located at the center of the insulation core layer 3, and its diameter is 10 mm.

[0055] In this embodiment, the diameter of the anchor ...

Embodiment 2

[0060] In this embodiment, the overall size of the inner steel wire mesh 1 and the outer layer steel wire mesh 2 is 1m 2 , the overall size is 1m*1m, the diameter of the steel wire is 3mm, and the size of the square hole is 900mm 2 ; The distance between the inner steel wire mesh 1 and the outer layer steel wire mesh 2 is 50mm.

[0061] In this embodiment, the thermal insulation core layer 3 is formed by bonding ceramic wool board and polystyrene board. The ceramic wool board is a plate made of aluminum silicate ceramic fiber, and its thermal conductivity is 0.03W / (m·k). The combustion performance level is A1 (GB 8624-2012), and the thermal conductivity of the polystyrene board is 0.02W / (m·k). The thickness of the ceramic wool board is 30mm, the thickness of the polystyrene board is 20mm, the overall size is cut to 1.03m*1.03m, and the interface width (the size of the insulation core layer 3 protruding from the inner and outer steel mesh layers) is 0.03m. The cement column 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com