Preparation method of rice straw brick and its product and application

A technology of straw straw and mass fraction is applied in the field of preparing straw straw bricks, which can solve the problems such as the inability to play the role of straw bricks well, achieve anticorrosion effect, good thermal performance, small volume change, and is beneficial to large-scale production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

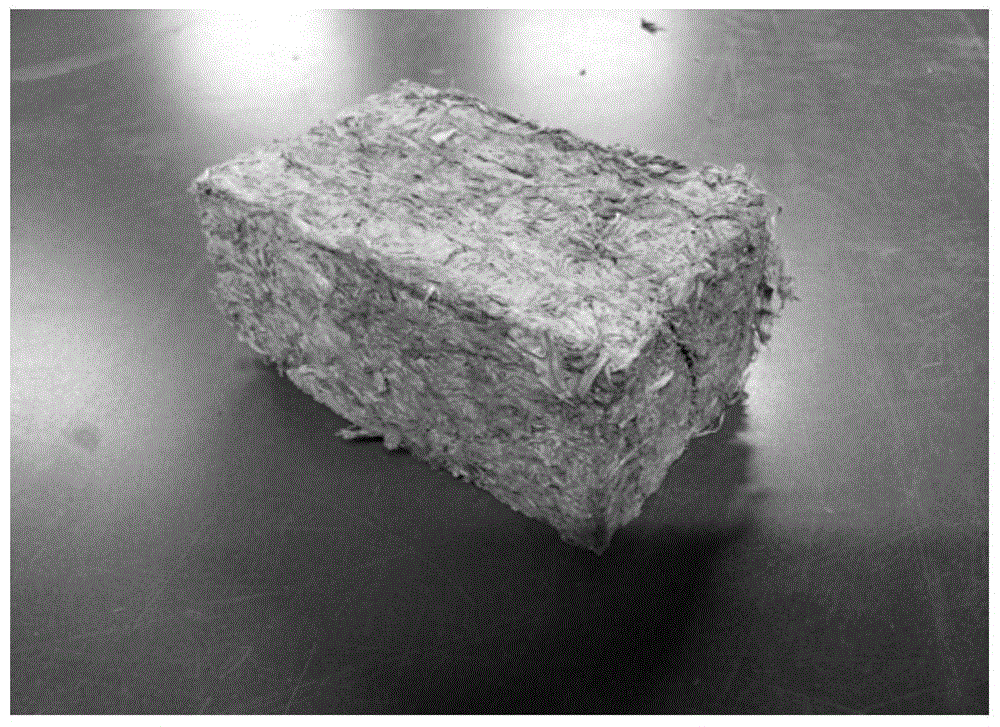

[0027] A novel preparation method of rice straw bricks, the steps are as follows:

[0028] (1) cutting the straw stalks;

[0029] (2) Submerge the cut rice straw in NaOH solution, stir evenly and soak for a period of time;

[0030] (3) filter the soaked rice straw and wash with water for 3-4 times;

[0031] (4) dehydrating and cold-pressing the filtered rice straw;

[0032] (5) Carry out natural maintenance on the bricks obtained after demoulding to obtain straw bricks.

Embodiment 1

[0033] The optimization of the preparation method condition of embodiment 1 rice straw brick

[0034] The present invention optimizes the preparation method of rice straw from the five aspects of NaOH solution immersion concentration, temperature, immersion time, forming pressure, and natural curing time, establishes the best preparation conditions and methods, and measures its physical properties and thermal conductivity The coefficients confirm the reliability of the method.

[0035] 1. Determination of soaking concentration of NaOH solution

[0036] In order to explore the influence of different concentrations of sodium hydroxide solution on the physical properties of straw bricks, the mass fraction of 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8% sodium hydroxide solution was used to treat the straw bricks. After soaking and softening treatment, 8 groups of test pieces were pressed respectively, with 3 pieces in each group. The size is unified as: 160×40×40mm, which will be marked sepa...

Embodiment 2

[0049] Example 2 Experimental Verification of the Preparation Method of Rice Straw Bricks

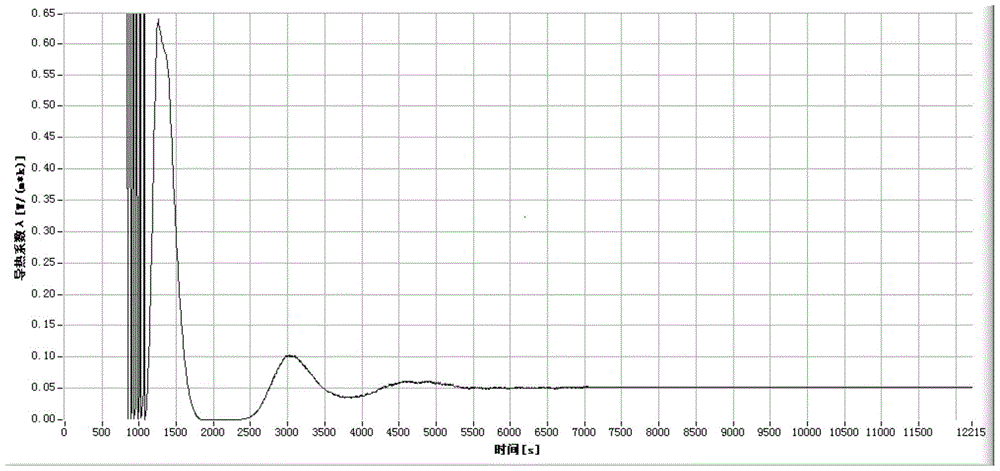

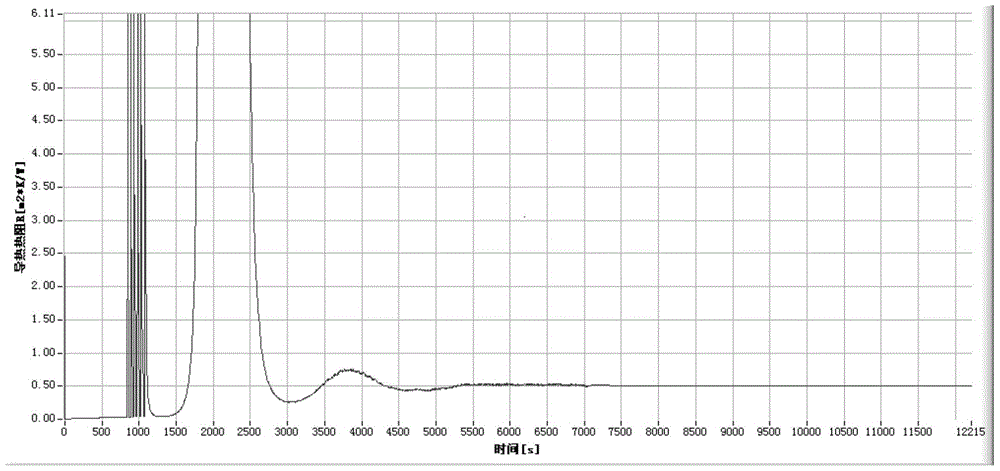

[0050] 1. Research on thermal conductivity of straw bricks

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com