Fuzzy gain scheduling prediction control-based control method for boiler-turbine coordination system

A gain scheduling and predictive control technology, applied in control/regulation systems, general control systems, adaptive control, etc., can solve problems such as the inability to guarantee the global optimality of the unit and the large difference between the peak and valley of the power grid load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

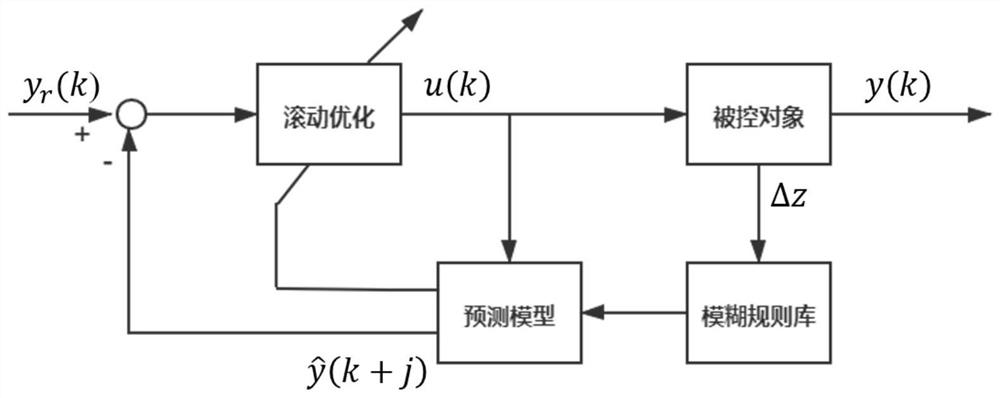

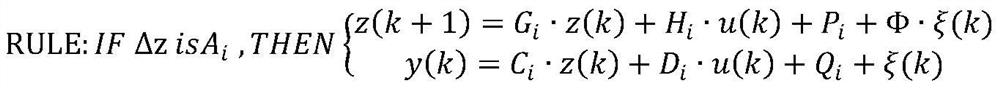

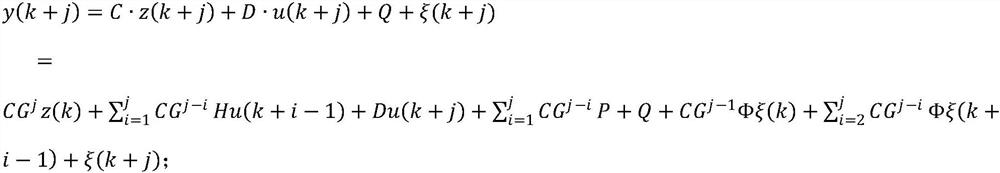

[0070] like figure 1 Shown is a schematic diagram of a furnace coordinated control system based on fuzzy gain scheduling predictive control. The control method is an intelligent control method that combines nonlinear modeling method, fuzzy logic reasoning theory and predictive control technology. The controlled object is the furnace In a coordinated system, the dynamic characteristics of the system will change according to the load requirements. z is a state variable reflecting the dynamic characteristics of the system, and Δz is used as a fuzzy gain scheduling variable. component parameters, that is, the state space model of the machine-furnace coordination system under this working condition; the predictive controller uses this model to predict the future N of the system p step output Carry out rolling optimiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com