Dynamics optimization simulation analysis method for driving mechanism of rail-mounted inspection robot

A technology for inspection robots and driving mechanisms, applied in the field of robots, can solve the problems of not considering the influence of dynamics, modeling errors, wasting time, etc., to avoid duplication of work and modeling errors, improve analysis accuracy, and simplify the analysis process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

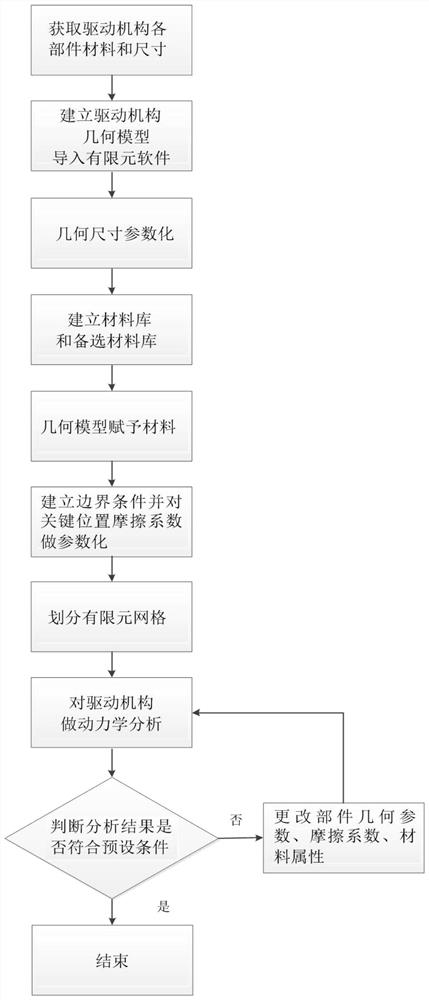

[0034] Such as figure 1 A dynamic optimization simulation analysis method for the driving mechanism of an orbital inspection robot includes the following steps:

[0035] Step S101: Obtain the material properties and dimensions of the drive motor, motor reducer, gear set, drive wheel set, deep groove ball bearing, bracket and guide rail of the drive mechanism of the inspection robot from the design drawing. In this example, the overall track-type inspection robot has an overall size of 800mm×400mm×520mm, a running speed of 0.8m / s, and a total mass of 28.6kg. The main material of the driving motor is die-casting aluminum, and the external dimensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com