Display panel and method of making the same

A display panel and substrate substrate technology, which is applied in manufacturing tools, welding equipment, laser welding equipment, etc., can solve problems such as reduced machine life, cutting failure, and poor wiring, so as to improve reliability, reduce costs, and reduce laser welding. The effect of cutting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following disclosure provides many different embodiments or examples for implementing different structures of the present application. for

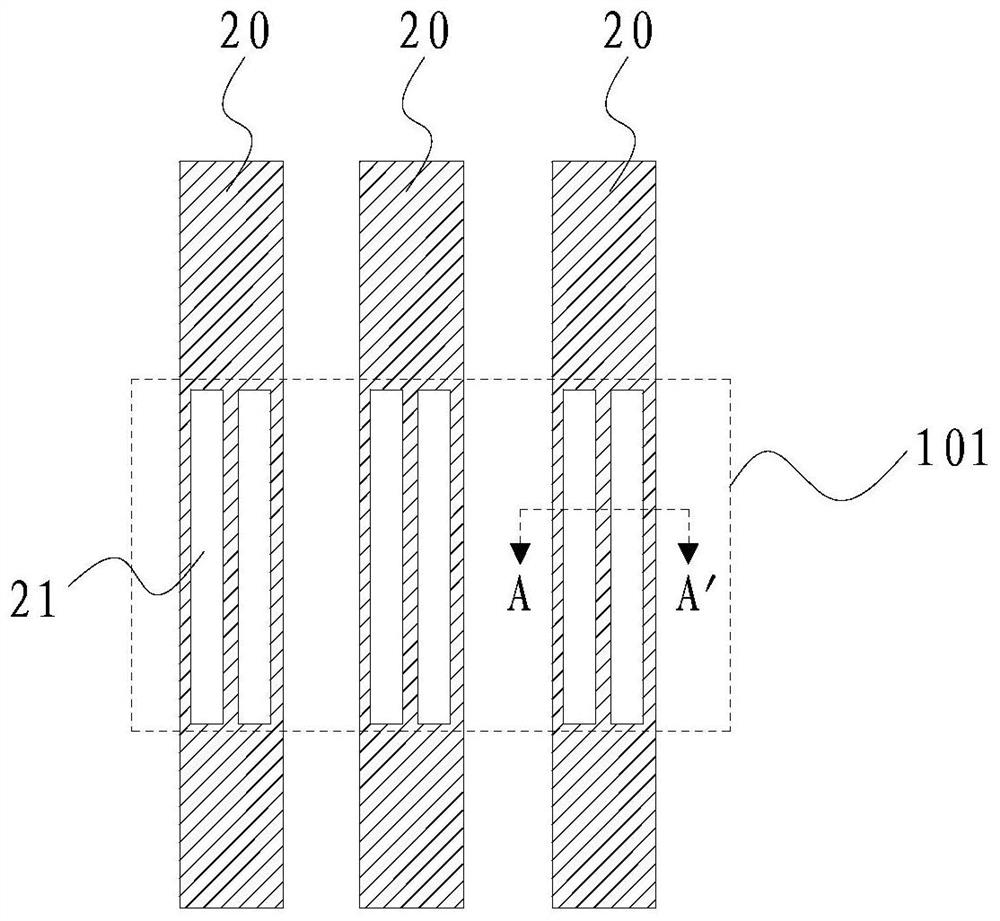

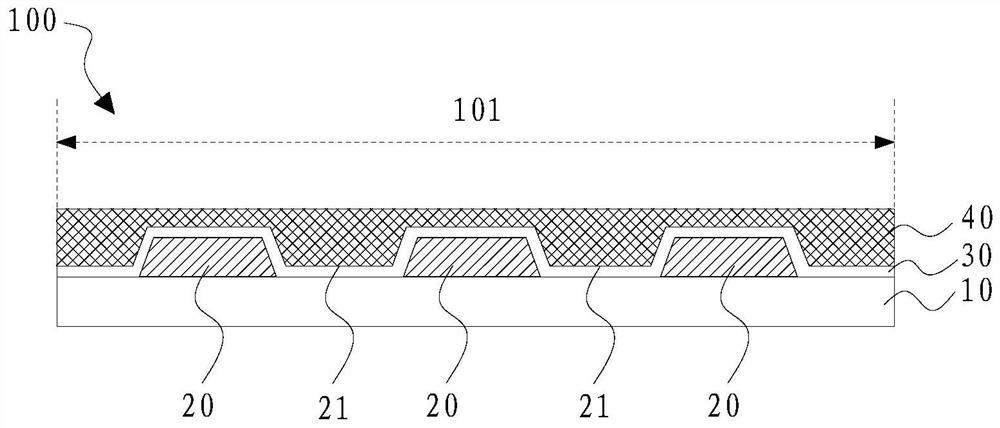

[0035] Please refer to FIG. 1 and FIG. 2, an embodiment of the present application provides a display panel 100, including a base substrate 10, arranged on

[0038] In the embodiment of the present application, the portion of the shorting bar 20 located in the cutting area 101 is patterned and designed.

[0039] Specifically, the shorting bar 20 may include at least one slit-shaped opening 21, and the slit-shaped opening 21 is located at the

[0041] It can be understood that, in other embodiments, the portion of the shorting bar 20 located in the cutting area 101 may be

[0042] Please refer to FIG. 1, in an embodiment, the organic flat layer 40 can completely cover the shorting bar 20.

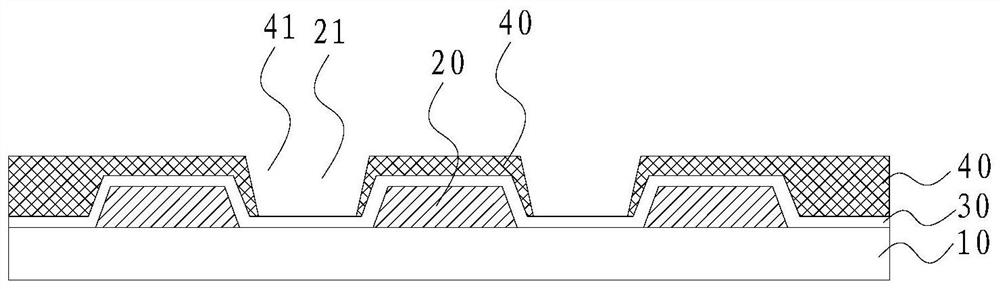

[0043] Please refer to FIG. 3, in other embodiments, the organic flat layer 40 includes a first groove 41, the first groove

[0045] When the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com