Novel ammonia-containing tail gas absorption process

A tail gas absorption and tail gas technology, applied in the direction of gas treatment, ammonium sulfate, membrane technology, etc., can solve the problems of unsatisfactory treatment effect, environmental pollution, cost, etc., and achieve the effect of not being easy to secondary pollution, reducing pollution, and absorbing ammonia Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

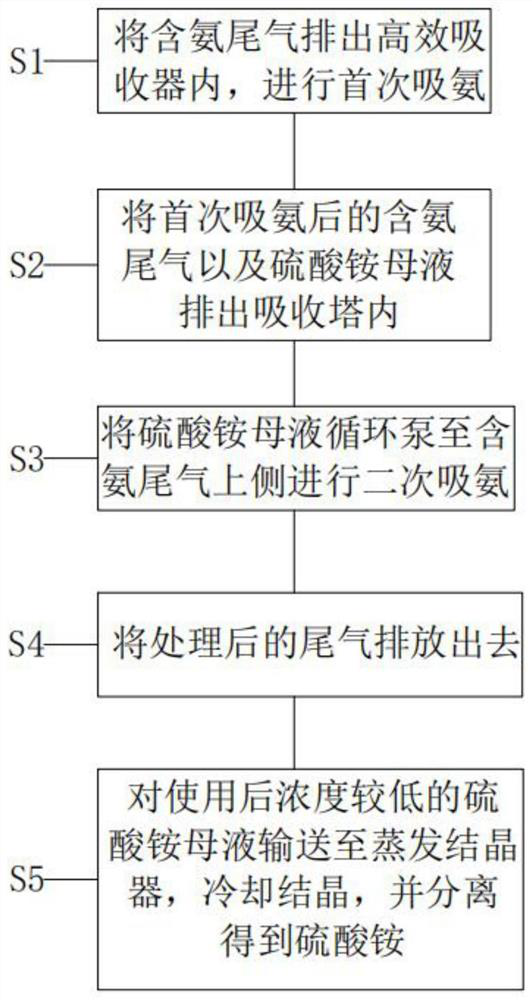

[0026] see figure 1 , the present invention provides the following technical solutions:

[0027] A novel ammonia-containing tail gas absorption process, comprising the following steps:

[0028] S1: First discharge the ammonia-containing tail gas from the water inlet pipe, and spray the ammonium sulfate mother liquor through the jet pump in the high-efficiency absorber, so that it contacts with the ammonia-containing tail gas, and absorbs the ammonia in the ammonia-containing tail gas for the first time;

[0029] S2: After the ammonia-containing tail gas is absorbed for the first time, the ammonium sulfate mother liquor enters the absorption tower through the liquid outlet at the lower end of the high-efficiency absorber, and is located at the lower side of the absorption tower. The mother liquor flow is at the bottom of the absorption tower, while the ammonia-containing tail gas after the first absorption rises;

[0030] S3: At this time, the rising ammonia-containing tail g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com