The Method of Involute Helical Double Forming Surface into Point Contact Toroidal Worm Pair

A toroidal worm and point contact technology is applied to the tooth surface forming of the involute helical double-shaped surface respectively developed into a toroidal worm and a worm gear, and the involute spiral double-shaped surface developed into a point contact toroidal worm pair. It can solve the problems of no regrindability, insensitivity to errors and high bearing capacity of hob or shaving cutter, so as to avoid complex manufacturing, reduce sensitivity and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described below according to the accompanying drawings.

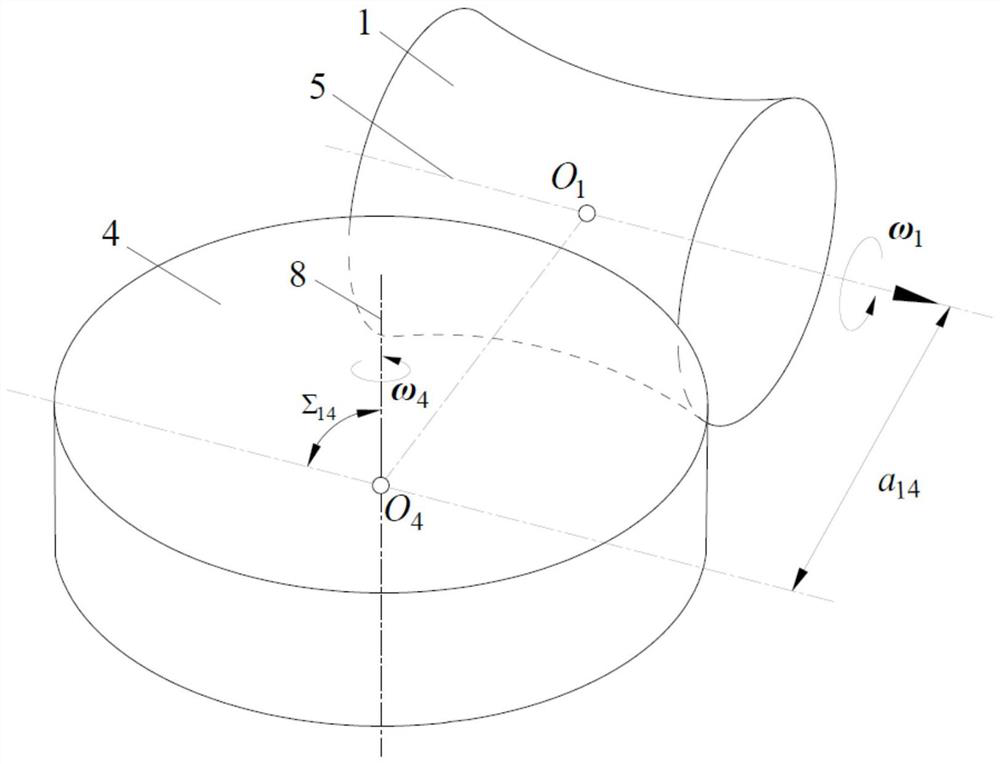

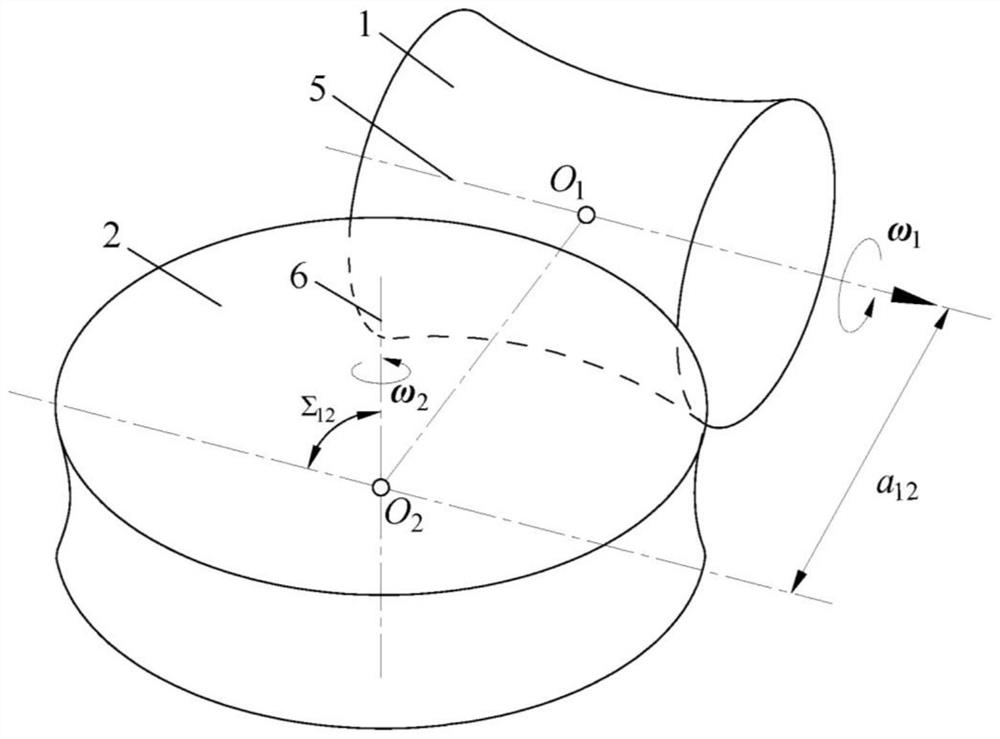

[0014] The relevant parameters for designing the toroidal worm pair are: the number of 1 head of the right-handed toroidal worm z 1 = 1, right-handed worm gear 2 teeth number z 2 =45, constituting the axis angle Σ 12 =90°, center distance a 12 =90.5mm, transmission ratio i 12 =45 involute spiral double production shape surface primary envelope point contact ring surface worm drive, worm working length L w1 = 30mm.

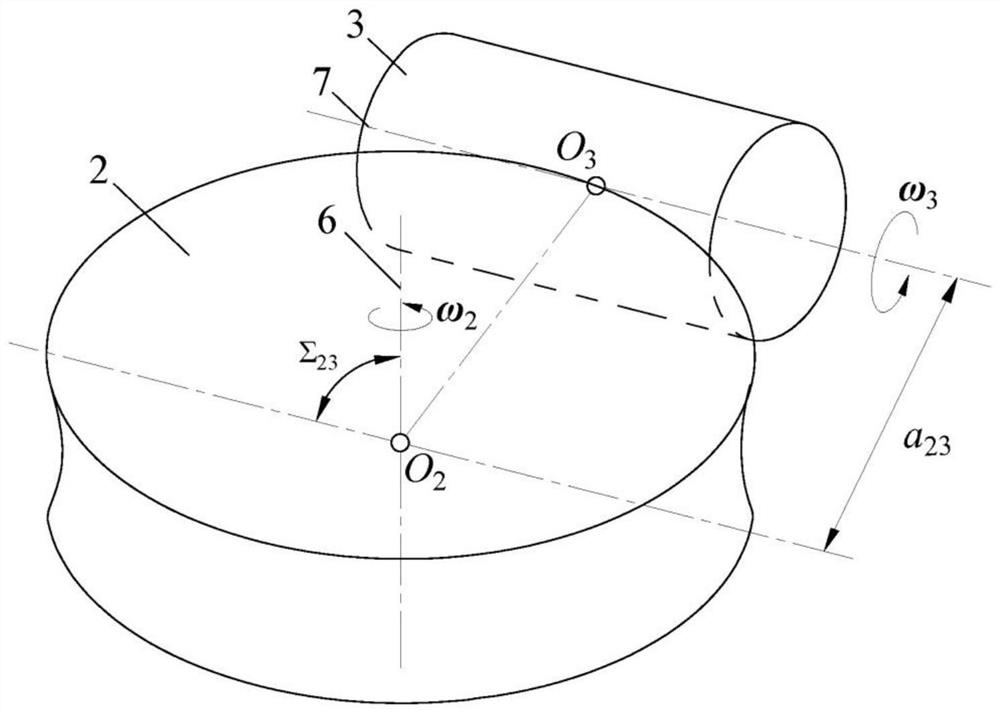

[0015] According to the design requirements, the relevant parameters for selecting the involute cylindrical worm cutter 3 are: the number of 3 heads of the right-handed involute cylindrical worm cutter z 3 =2. Lead angle of indexing circle γ 3 =10.73°, axial modulus m x3 =3.6mm, graduation circle diameter d 3 =38mm, diameter of dedendum circle d f3 =29.51mm, addendum circle diameter d a3 =45.07mm, base circle radius r b3 =8.65mm. The relevant pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com