Composite material fiber winding forming device based on robot

A composite material fiber and winding forming technology, which is applied in the field of fiber winding composite material processing, can solve the problems of low degree of freedom, complex structure of fiber winding machine, and single applicable product structure, so as to improve adaptability, reduce design constraints, and improve structure performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

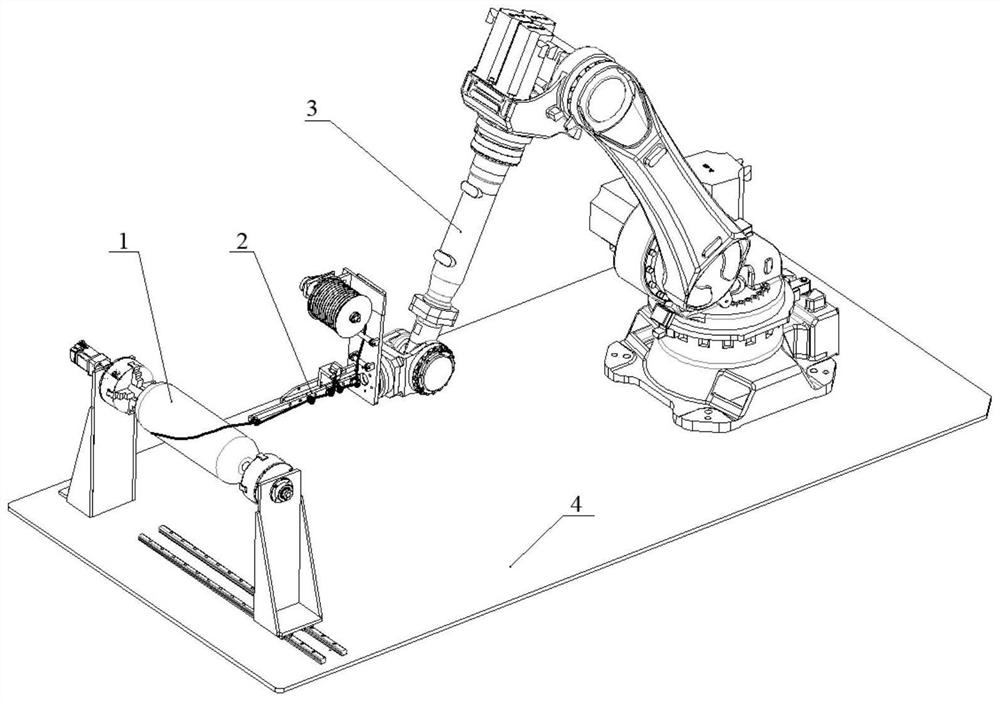

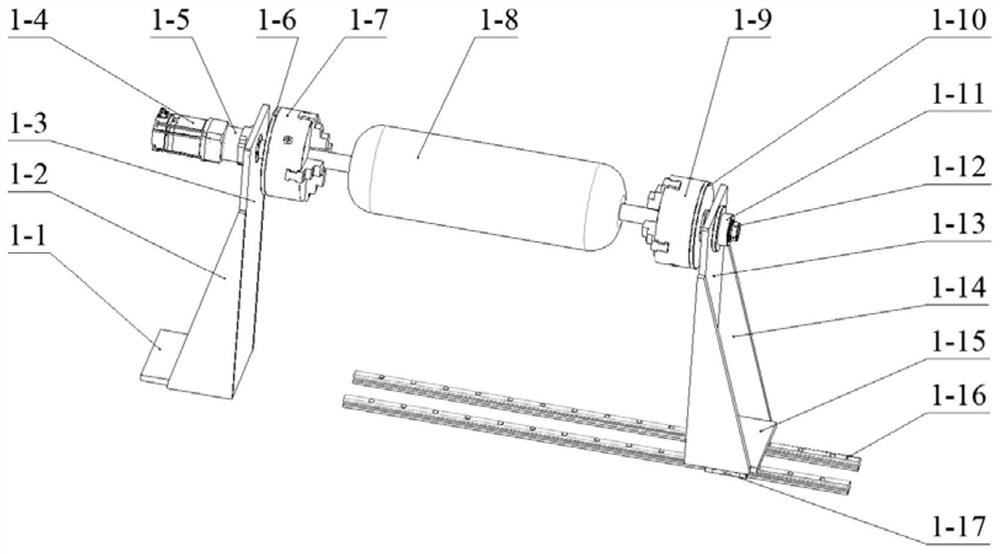

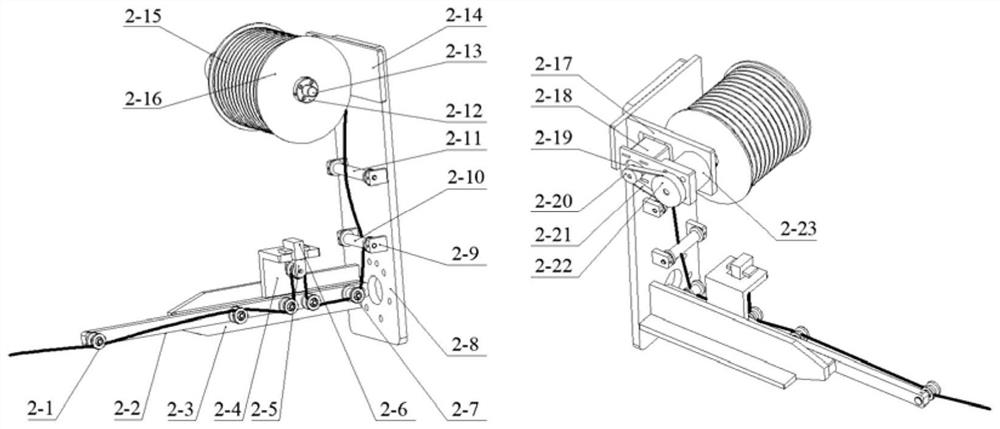

[0025] Such as Figure 1 to Figure 3 As shown, a robot-based composite fiber winding forming device of the present invention includes a multi-degree-of-freedom industrial robot body 3, a fiber winding head device 2 and a mandrel rotating device 1, a multi-degree-of-freedom industrial robot body 3 and a mandrel rotating device 1 is installed on the bottom plate 4. Mandrel rotating device 1 comprises the winding mandrel 1-8 of rotation and is used to support the bearing of winding mandrel 1-8; The fiber wheel train adjustment module for adjusting the release path of the fiber material 2-15, the fiber tension detection device for detecting the tension of the fiber material 2-15 and feeding it back to the wire unwinding device, the wire unwinding device adjusts the fiber material 2 through the fiber gear train adjustment module -15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com