Erosion-resistant concrete and preparation process thereof

A concrete and corrosion-resistant technology, applied in the field of building materials, can solve the problems affecting the service life of concrete, achieve the effect of firm interface, good mechanical properties and durability, and reduce porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

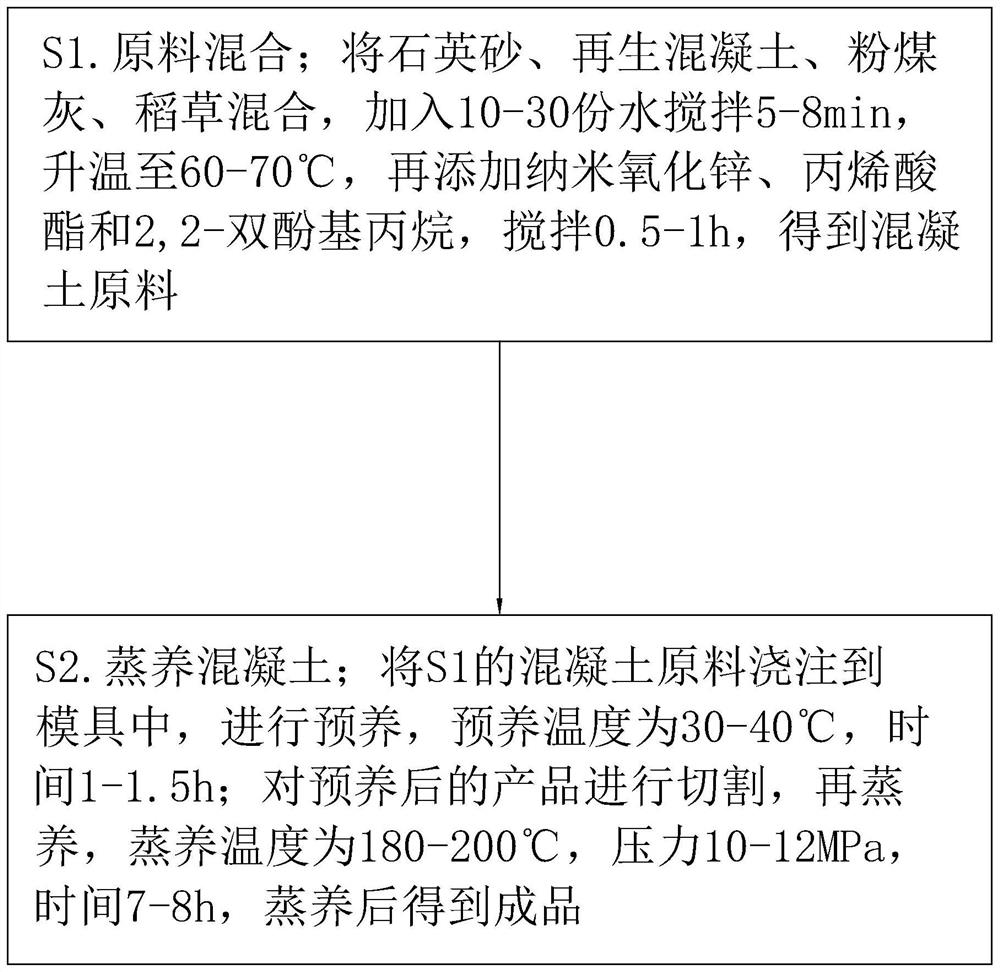

[0042] The invention discloses a corrosion-resistant concrete and its preparation process. figure 1 , the preparation process includes the following steps:

[0043] S1. Raw material mixing; mix quartz sand, recycled concrete, and fly ash, add straw cut into 20mm pieces while stirring, then add 130 parts of water and stir for 5 minutes, heat up to 60°C, and then add nano-zinc oxide and acrylate and 2,2-bisphenol-based propane, stirred for 0.5h to obtain concrete raw materials;

[0044] S2. Steam-cured concrete; pour the concrete raw materials of S1 into the mold and vibrate for 60s, then pre-cure, the pre-curing temperature is 30°C, and the time is 1h; cut the pre-cured products, and then steam-cure, steam-curing temperature The temperature is 180°C, the pressure is 10MPa, the time is 7h, and the finished product is obtained after steaming.

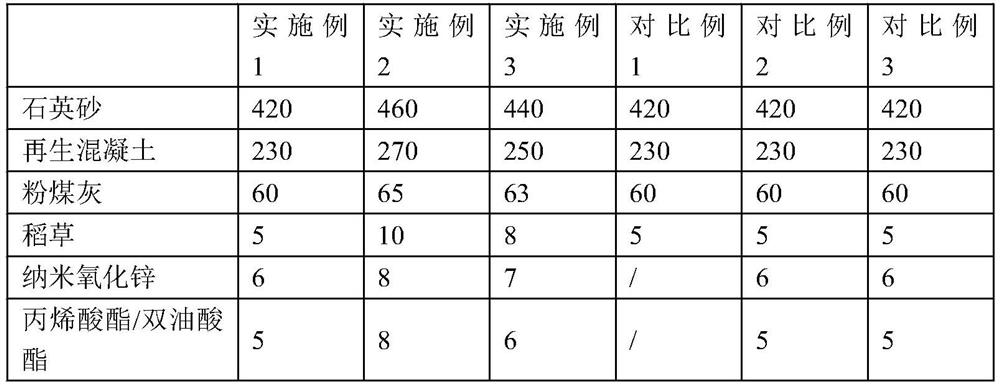

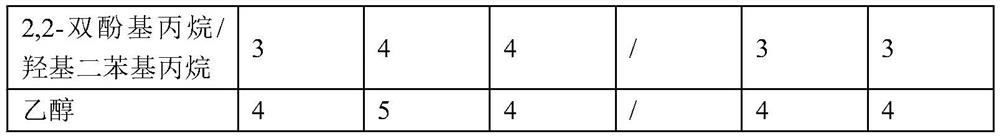

[0045] The content of each component is shown in Table 1 below.

Embodiment 2

[0047] The invention discloses a corrosion-resistant concrete and its preparation process. figure 1 , the preparation process includes the following steps:

[0048] S1. Raw material mixing; mix quartz sand, recycled concrete, and fly ash, add straw cut into 20mm pieces while stirring, then add 170 parts of water and stir for 8 minutes, heat up to 70°C, and then add nano-zinc oxide and acrylate and 2,2-bisphenol propane, stirred for 1h to obtain concrete raw material;

[0049] S2. Steam-cured concrete; pour the concrete raw materials of S1 into the mold and vibrate for 60s, then pre-cure, the pre-curing temperature is 40°C, and the time is 1.5h; cut the pre-cured products, then steam-cure, and steam-cure The temperature is 200°C, the pressure is 12MPa, the time is 8h, and the finished product is obtained after steaming.

[0050] The content of each component is shown in Table 1 below.

Embodiment 3

[0052] The invention discloses a corrosion-resistant concrete and its preparation process. figure 1 , the preparation process includes the following steps:

[0053] S1. Raw material mixing; mix quartz sand, recycled concrete, and fly ash, add straw cut into 20mm pieces while stirring, then add 150 parts of water and stir for 6 minutes, heat up to 65°C, and then add nano-zinc oxide and acrylate and 2,2-bisphenol propane, stirred for 0.8h to obtain concrete raw material;

[0054]S2. Steam-cured concrete; pour the concrete raw materials of S1 into the mold and vibrate for 60s, then pre-cure, the pre-curing temperature is 35°C, and the time is 1h; cut the pre-cured products, and then steam-cure, steam-curing temperature The temperature is 190°C, the pressure is 11MPa, the time is 7.5h, and the finished product is obtained after steam curing.

[0055] The content of each component is shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com