Water-tree-resistant crosslinked polyethylene insulating material

A cross-linked polyethylene, anti-water tree technology, applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc., can solve the problems of non-self-recoverable insulation of cable insulation, economic loss and social impact, and achieve good compatibility Sexuality, significant effect, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

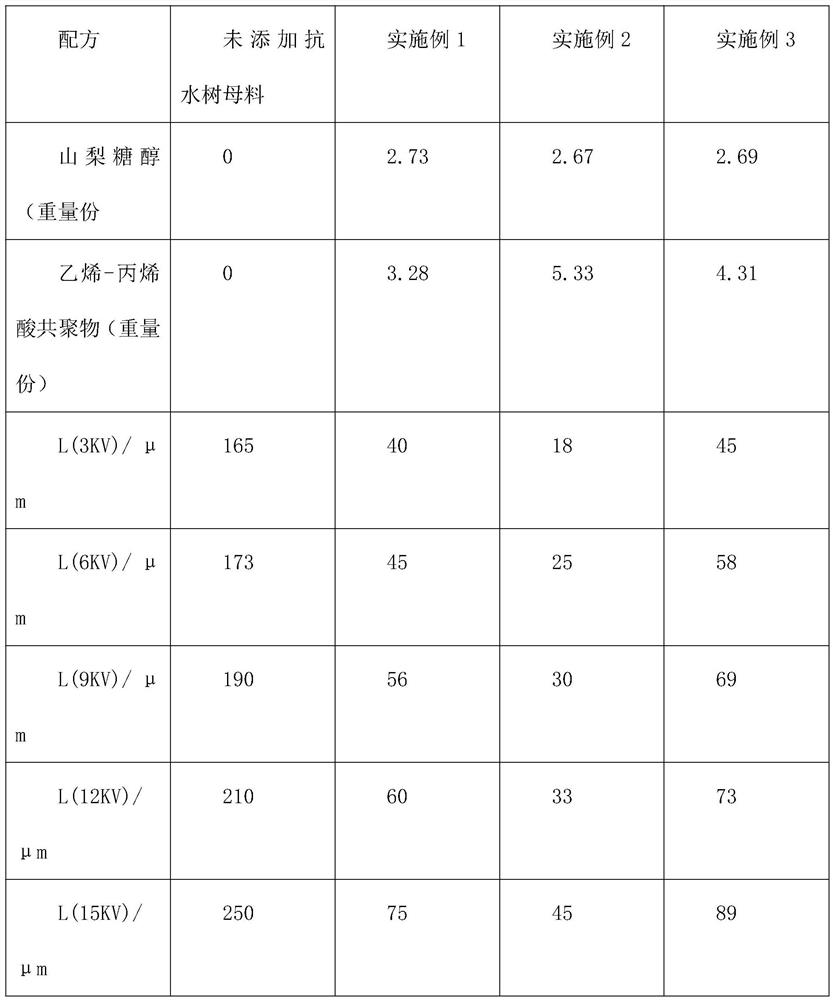

Embodiment 1

[0014] Embodiment 1: A water-tree-resistant cross-linked polyethylene insulating material is made of the following raw materials in parts by weight, wherein: 80 parts of low-density polyethylene, 6 parts of water-tree-resistant masterbatch, 0.7 parts of antioxidant, cross-linked 2.2 parts of linking agent, 0.8 parts of co-crosslinking agent, 2 parts of compatibilizer.

[0015] In this embodiment, the melt flow index of the low-density polyethylene is 1.9 g / 10 min.

[0016] In this example, the anti-water tree masterbatch is composed of sorbitol and ethylene-acrylic acid copolymer, wherein the mass ratio of sorbitol to ethylene-acrylic acid copolymer is 1:1.2.

[0017] In this embodiment, the antioxidant is a mixture of antioxidant 300, antioxidant DSTP, and antioxidant DLTP, wherein the mass ratio of antioxidant 300, antioxidant DSTP, and antioxidant DLTP is 1:0.7:0.7.

[0018] In this embodiment, the crosslinking agent is dicumyl peroxide.

[0019] In this embodiment, the c...

Embodiment 2

[0022] Embodiment 2: basically the same as Embodiment 1, the difference is that: a water-tree-resistant cross-linked polyethylene insulating material is made of the following raw materials in parts by weight, wherein: 110 parts of low-density polyethylene, water-resistant 8 parts of tree masterbatch, 0.9 parts of antioxidant, 2.8 parts of crosslinking agent, 1 part of co-crosslinking agent, 3 parts of compatibilizer.

[0023] In this embodiment, the melt flow index of the low-density polyethylene is 2.3 g / 10 min.

[0024] In this example, the anti-water tree masterbatch is composed of sorbitol and ethylene-acrylic acid copolymer, wherein the mass ratio of sorbitol to ethylene-acrylic acid copolymer is 1:2.

[0025] In this embodiment, the antioxidant is a mixture of antioxidant 300, antioxidant DSTP, and antioxidant DLTP, wherein the mass ratio of antioxidant 300, antioxidant DSTP, and antioxidant DLTP is 1:0.9:0.9.

[0026] In this embodiment, the crosslinking agent is di-te...

Embodiment 3

[0030] Embodiment 3: Basically the same as Embodiment 1 and Embodiment 2, the difference is that: a kind of anti-water tree cross-linked polyethylene insulating material is made of the following raw materials in parts by weight, wherein: low density polyethylene 95 7 parts, 7 parts of anti-water tree masterbatch, 0.8 parts of antioxidant, 2.5 parts of crosslinking agent, 0.9 parts of co-crosslinking agent, 2.5 parts of compatibilizer.

[0031] In this embodiment, the melt flow index of the low-density polyethylene is 2.1 g / 10 min.

[0032] In this example, the anti-water tree masterbatch is composed of sorbitol and ethylene-acrylic acid copolymer, wherein the mass ratio of sorbitol to ethylene-acrylic acid copolymer is 1:1.6.

[0033] In this embodiment, the antioxidant is a mixture of antioxidant 300, antioxidant DSTP and antioxidant DLTP, wherein the mass ratio of antioxidant 300, antioxidant DSTP, and antioxidant DLTP is 1:0.8:0.8.

[0034] In this embodiment, the crosslin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com