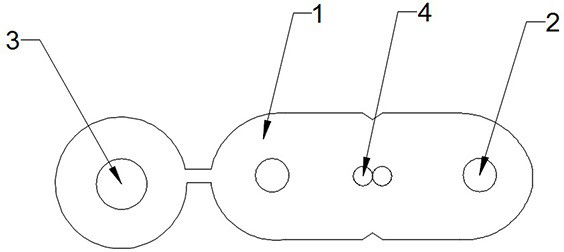

Low-smoke halogen-free self-supporting butterfly-shaped leading-in optical cable with non-metal reinforcers

A non-metallic strength member and a technology for introducing optical cables, which are applied in the field of optical cables, can solve problems such as the reduction of mechanical properties of sheath materials, and achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

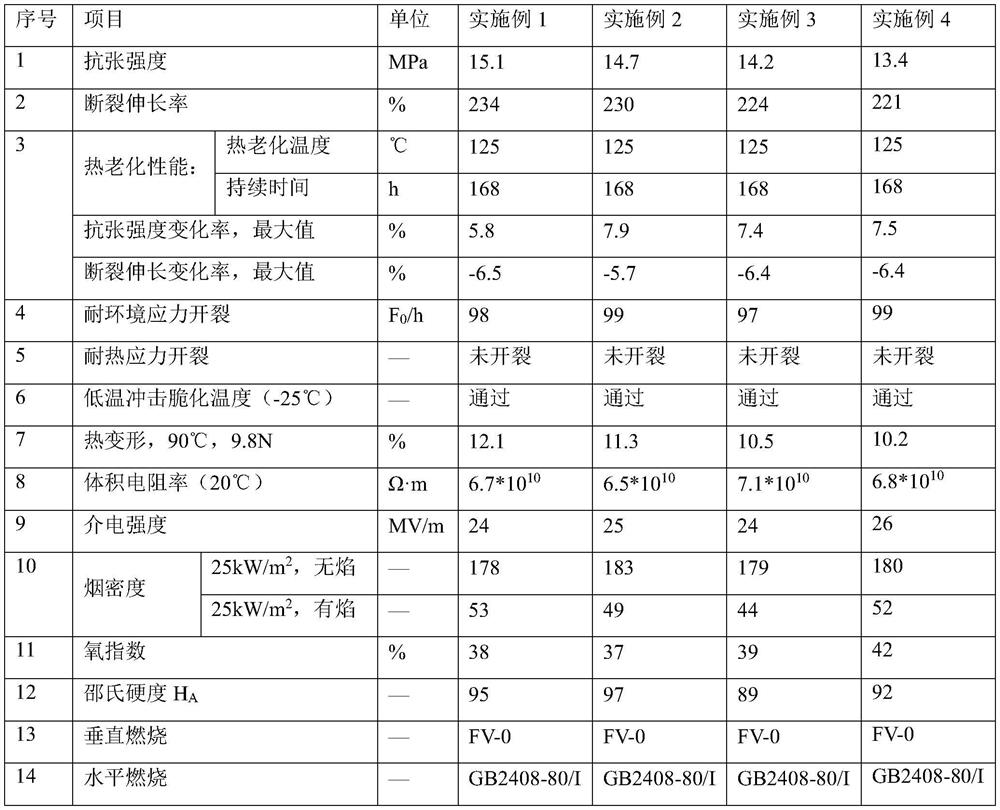

Examples

Embodiment 5

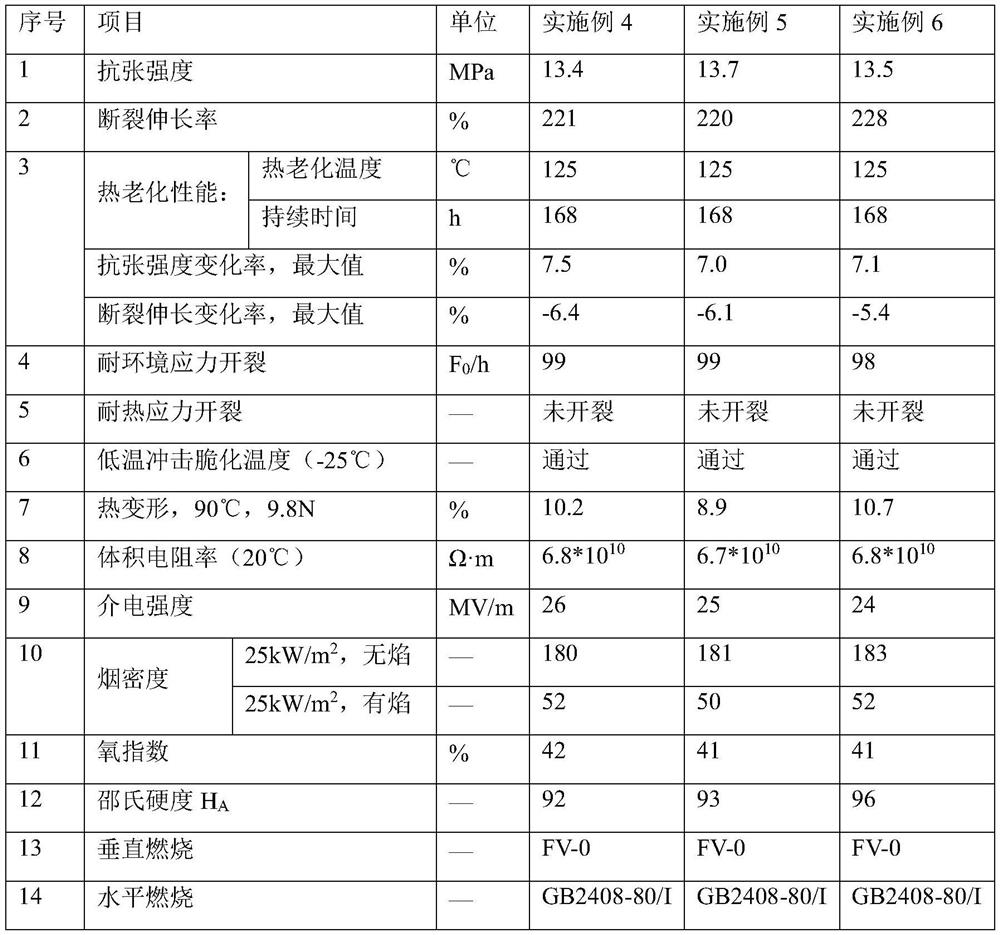

[0029] Examples 5-6, in order to further explore the influence of the particle size of the zeolite powder on the performance of the sheath, when preparing the sheath material, add zeolite powder with different particle sizes, the particle size of the zeolite powder added in Example 5 is 200 mesh , the particle diameter of the zeolite powder added in embodiment 6 is 120 meshes, other raw materials are the same as in embodiment 4, the raw materials of specific embodiments 5-6 are as shown in table 3, and the preparation method of sheath material is exactly the same as embodiment 4 .

[0030] The raw material list of table 3 embodiment 5-6

[0031] raw material Example 4 Example 5 Example 6 LDPE 90 90 90 EVA 60 60 60 magnesium hydroxide 40 40 40 Zeolite powder 10 (325 mesh) 10 (200 mesh) 10 (120 mesh) Dioctyl Thiodipropionate 0.1 0.1 0.1 Titanate coupling agent (NDZ-105) 0.5 0.5 0.5 DNP (antioxidant) 0.1 0....

Embodiment 7

[0036] Examples 7-12, in order to further explore the influence of the preparation process of the sheath material on the performance of the sheath, when banburying, the pressure of Example 7 is set to normal pressure, and the pressure of Example 8 is 2 atmospheres, and the implementation The pressure of example 9 is 2.5 atmospheres, the pressure of embodiment 10 is 3.2 atmospheres, the pressure of embodiment 11 is 3.5 atmospheres, the pressure of embodiment 12 is 3.8 atmospheres, other reaction conditions and each raw material consumption and embodiment 4 The same, and the obtained sheath was subjected to a performance test. The sheaths obtained in Examples 7-9 and Example 12 did not meet the performance standards, and the sheath materials obtained in Examples 10-11 met the performance standards, as shown in Table 5.

[0037] Table 5 embodiment 4,10,11 sheath material performance test result

[0038]

[0039]

[0040] It can be seen from Table 5 that the overall performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com