A specifically tunable high-throughput ultra-diffraction-limited focal spot generation device

A technology that exceeds the diffraction limit and generates devices, applied in the field of optical engineering, can solve the problems of low flux and slow speed, and achieve the effects of compact design, high integration, and speed and resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

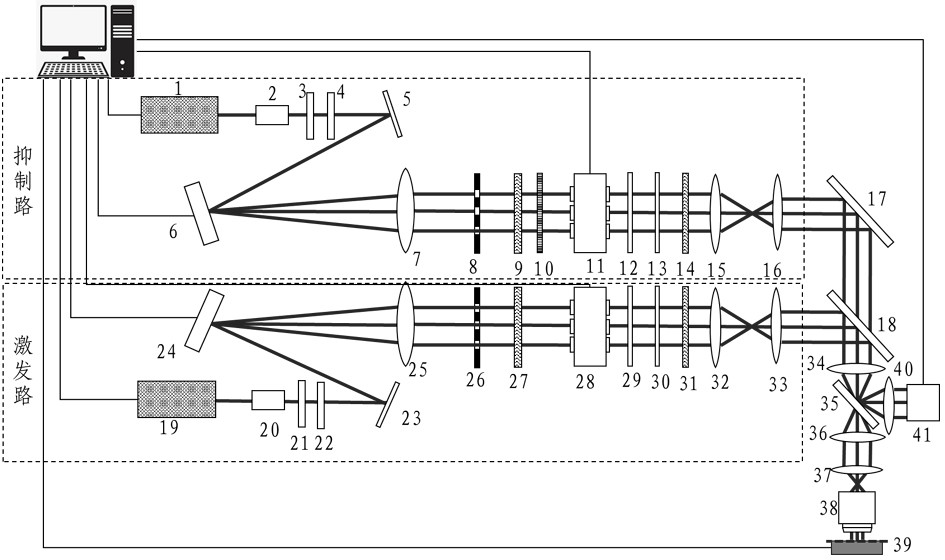

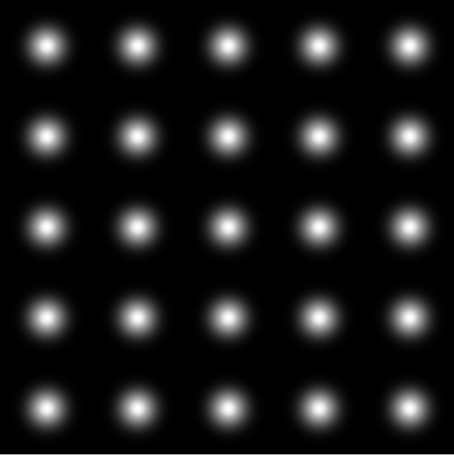

[0019] The invention suppresses the laser light emitted by the optical laser at the focal plane of the objective lens to form a high-flux dark spot array, and the light emitted by the excitation laser forms a high-flux solid light spot array, and the dark spot suppresses the action area of the solid light spot to realize high-flux ultra-high Diffraction-limited focal spot arrays; use ultra-diffraction-limited focal spots to perform parallel super-resolution imaging or laser direct-writing processing of samples placed on the sample stage.

[0020] The present invention includes two paths of light with different wavelengths, one path is a suppression path for generating large-flux dark spots, and the other path is an excitation path for generating corresponding solid light spots; both paths of light use spatial light modulators to convert laser light The beam is split to form a laser array, and then a device that generates a high-throughput dark spot array is used to modulate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com