Film bulk acoustic resonator and manufacturing method thereof

A thin-film bulk acoustic wave and manufacturing method technology, applied in electrical components, impedance networks, etc., can solve problems such as the inability to further improve the quality factor and the inability to meet high-performance radio frequency systems, so as to improve acoustic wave loss, improve device performance, and block shear waves. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

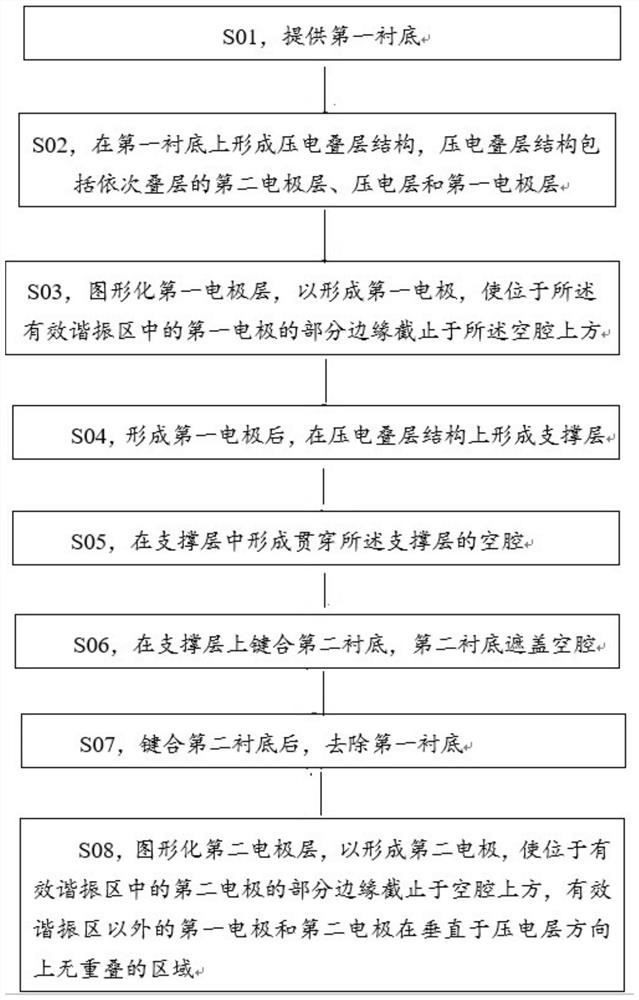

[0050] refer to image 3 and Figure 4 , performing steps S01 and S02 , providing a first substrate 100 , and forming a piezoelectric stack structure 120 on the first substrate 100 . The piezoelectric stack structure 120 includes a second electrode layer 102, a piezoelectric layer 103 and a first electrode layer 104, wherein the piezoelectric layer 103 is located between the first electrode layer 104 and the second electrode layer 102, and the first electrode layer 104 is opposite to the second electrode layer 102 .

[0051] The material of the first substrate can be at least one of the materials mentioned below: silicon (Si), germanium (Ge), silicon germanium (SiGe), silicon carbon (SiC), silicon germanium carbon (SiGeC), arsenic Indium (InAs), gallium arsenide (GaAs), indium phosphide (InP) or other III / V compound semiconductors, including multilayer structures composed of these semiconductors, or silicon-on-dielectric (SOI), dielectric Silicon-on-layer (SSOI), silicon-ge...

Embodiment 2

[0066] refer to Figure 3-Figure 6 and Figure 13-Figure 19 , steps S01, S02, and S03 are the same as in Embodiment 1, and step S03 also includes, after the first electrode layer 104 is patterned, forming a first The number and depth of the grooves 106 and the first grooves 106 are not limited, and can be set according to different technical requirements. In this example, the number of the first groove 106 is one, the depth is the thickness of the piezoelectric layer 103, and the first groove 106 surrounds a part of the outer circumference of the first electrode 104'. The first groove 106 is ring-shaped with an opening, and the first electrode 104' is connected to the supporting layer 105 through the opening, so as to lead the first electrode 104' out and form a first pad in the non-effective resonance area. The method for forming the first groove 106 is similar to the method for forming the cavity 110a, and dry etching or a combination of wet etching and dry etching can be ...

Embodiment 3

[0069] see Figure 20 , on the basis of Example 2, after step S08 is performed, further comprising, forming a second groove 107 in the exposed piezoelectric layer 103 near the edge of the second electrode 102' in the area where the second electrode 102' is removed The structure and formation process of the second groove 107 refer to the relevant content of the first groove in Embodiment 2. In this example, there is one second groove, the depth is the thickness of the piezoelectric layer, and the second groove 107 surrounds the periphery of a portion of the second electrode 102'. The second groove 107 is ring-shaped with an opening, and the second electrode 102' is connected to the support layer 105 through the opening, so as to lead the second electrode 102' out and form a second pad 112 in the non-effective resonance area. In this example, the cross-sectional shape of the second groove 107 is a trapezoid with a narrow bottom and a wide top, and the angle between the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com