Method for mobile pressure swing adsorption oxygen production device

A pressure swing adsorption and production device technology, which is applied in the direction of oxygen preparation, separation methods, chemical instruments and methods, etc., can solve the problems of labor and material resources, poor safety, and high oxygen cost, and achieve improved safety, light weight, Effect of reducing oxygen cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

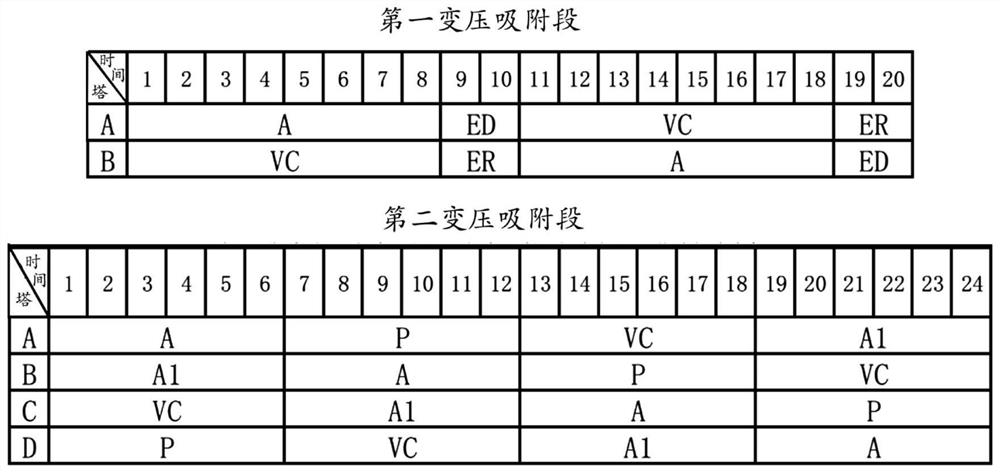

[0025] figure 1 It is the operation steps of each section of the adsorption tower and the sequence diagram of the switch of the program-controlled valve in Embodiment 1 of the present invention.

[0026] figure 2 It is a process flow diagram of Embodiment 1 of the present invention.

[0027] The feed air composition of the present embodiment is as follows:

[0028] Component O 2

N 2

Ar CO 2

other ∑ Concentration (%) (V) 20.93 78.03 0.932 0.03 0.078 100

[0029] Temperature: ≤40℃

[0030] Pressure: 0.05MPa(G)

[0031] Such as figure 2 As shown, vacuum pump P0101, vacuum buffer tank V0101, program-controlled valve, PLC control system, instrumentation, process pipeline fittings, adsorption towers T0101A and T0101B form the first pressure swing adsorption section, and the adsorbent filled in the adsorption tower is 5A molecular sieve or lithium Molecular sieve, running single-tower adsorption, pressure equalization and vacuuming p...

Embodiment 2

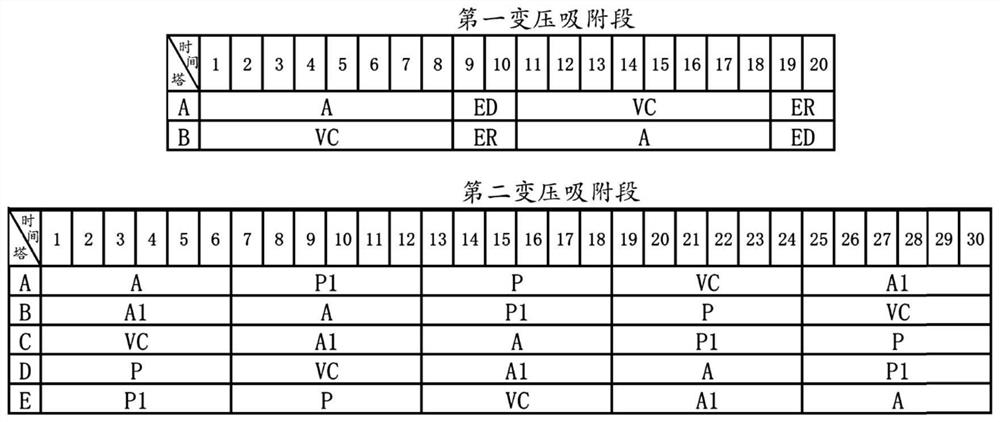

[0055] image 3 It is the operation steps of each section of the adsorption tower and the sequence diagram of the switching of the program-controlled valve in Embodiment 2 of the present invention.

[0056] Figure 4 It is a process flow diagram of Embodiment 2 of the present invention.

[0057] The feed air composition of the present embodiment is as follows:

[0058] Component O 2

N 2

Ar CO 2

other ∑ Concentration (%) (V) 20.93 78.03 0.932 0.03 0.078 100

[0059] Temperature: ≤40℃

[0060] Pressure: 0.05MPa(G)

[0061] Such as Figure 4 As shown, vacuum pump P0101, vacuum buffer tank V0101, program-controlled valve, PLC control system, instrumentation, process pipeline fittings, adsorption towers T0101A and T0101B form the first pressure swing adsorption section, and the adsorbent filled in the adsorption tower is 5A molecular sieve or lithium Molecular sieve, running single-tower adsorption, pressure equalization and vacuumin...

Embodiment 3

[0087] Figure 5 It is the operation steps of each section of the adsorption tower and the sequence diagram of the switch of the program-controlled valve in Embodiment 3 of the present invention.

[0088] Figure 6 It is the process flow diagram of embodiment 3 of the present invention.

[0089] The feed air composition of the present embodiment is as follows:

[0090] Component O 2

N 2

Ar CO 2

other ∑ Concentration (%) (V) 20.93 78.03 0.932 0.03 0.078 100

[0091] Temperature: ≤40℃

[0092] Pressure: 0.05MPa(G)

[0093] Such as Figure 6 As shown, vacuum pump P0101, vacuum buffer tank V0101, program-controlled valve, PLC control system, instrumentation, process pipeline fittings, adsorption towers T0101A, T0101B and T0101C constitute the first pressure swing adsorption section, and the adsorbent filled in the adsorption tower is 5A molecular sieve Or lithium molecular sieve, run single-tower adsorption, pressure equalization an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com