Method for preparing picromerite from magnesium sulfate subtype brine

A technology of magnesium sulfate subtype and langbeinite, which is applied in the chemical industry to achieve the effect of simple process operation and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

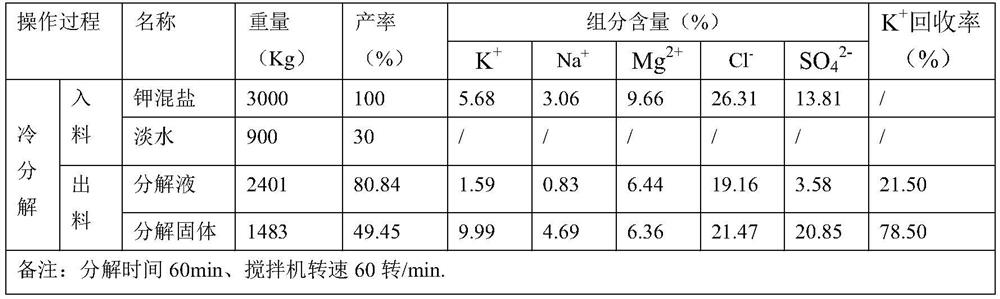

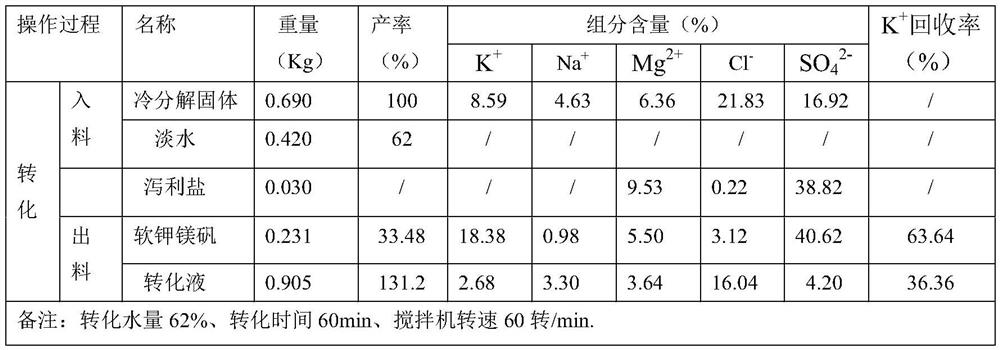

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in further detail below in conjunction with the embodiments.

[0029] 1 Test content

[0030] 1.1 Natural scale-up experiment in salt fields to produce potassium mixed salt

[0031] This test is a natural evaporation test in the summer salt field. A total of 6 times of brine irrigation and drying were carried out. The composition of the original brine used is shown in the following table:

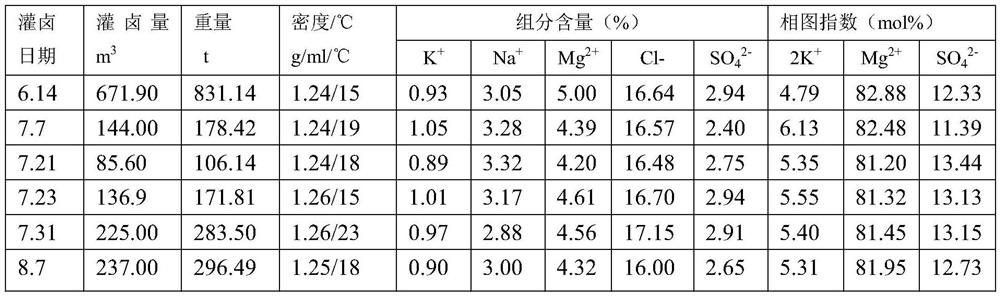

[0032] Table 1

[0033]

[0034] According to the characteristics of the brine, combined with the analysis of the phase diagram, the point of the phase diagram of this brine has been located at the three-phase co-saturation point of epsom salt, carnallite, and potassium halite, and there is no separate stage of epsom salt. When K in the mother liquor + When the content reaches 1.5% and the density of the mother liquor is about 1.29, the solid-liquid separation is carried out, and the solid phase is rock salt, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com