Landscape lake water replenishing and phosphorus control process

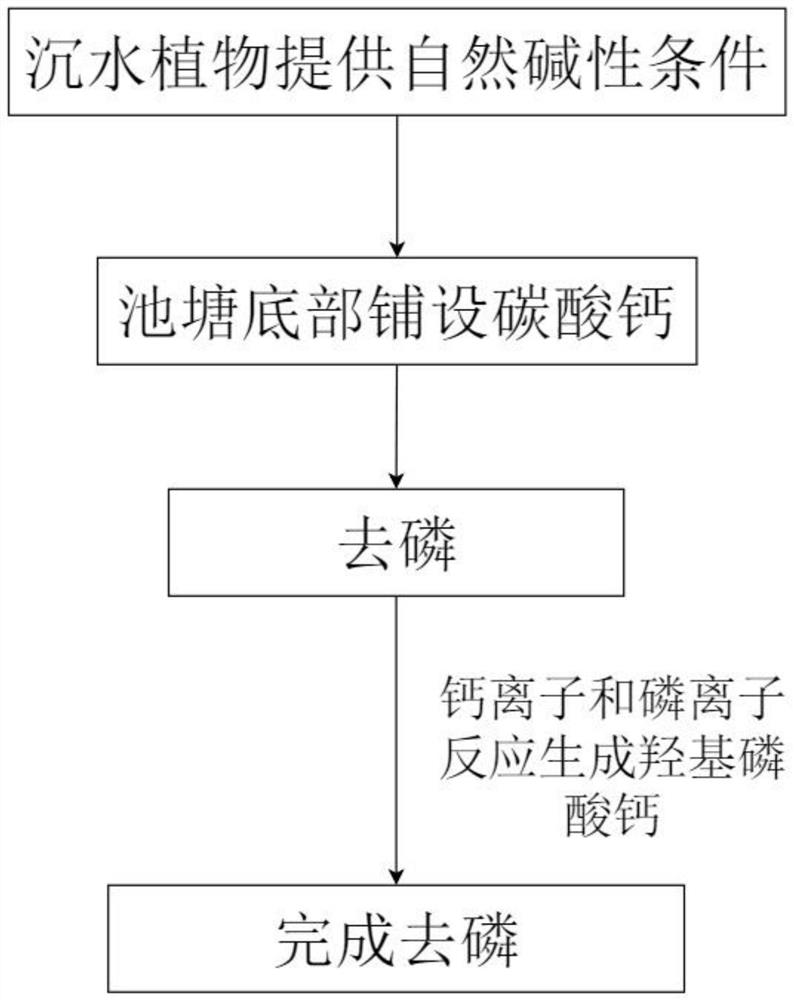

A technology for lakes and landscapes, applied in the field of water replenishment and phosphorus control in landscape lakes, can solve the problems of cumbersome steps, poor phosphorus removal effect, cumbersome steps in the phosphorus removal process, etc., and achieve the effect of simple process steps and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

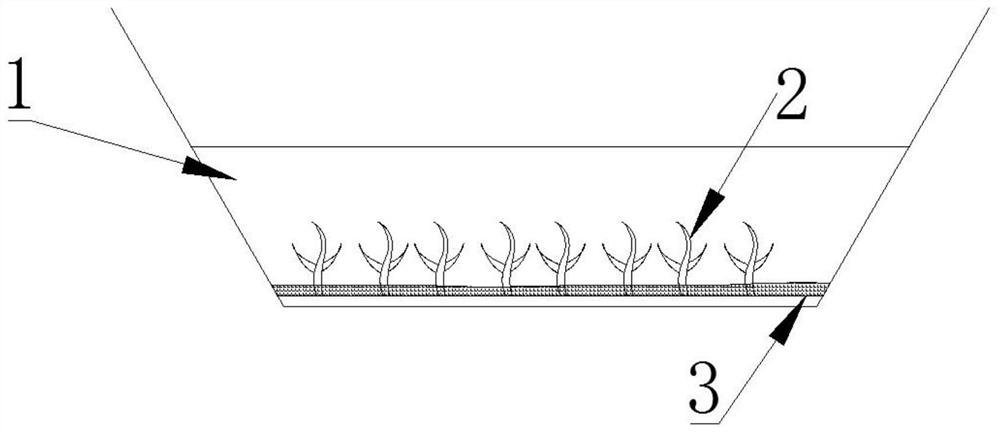

[0037] (1) Take the water in the pond and put them into three large water tanks with the same capacity respectively. The hydraulic retention time of the pond is 12h, and the hydraulic load is 0.08m 3 / m 2 · d, the coverage of submerged plants at the bottom of the pond is 40%, respectively marked with A1, B1, and C1, and the phosphorus content in the water in the three cups of A1, B1, and C1 is first detected at this time, and the detection data are shown in Table 1.

[0038] (2) Pour calcium carbonate with a particle size of 30mm into the A1 water tank, pour calcium carbonate with a particle size of 30mm into the B1 water tank, pour calcium carbonate with a particle size of 30mm into the C1 water tank, and cover the calcium carbonate in the three water tanks The thickness is 80mm, stirring three tanks at the same time.

[0039] (3) After the three water tanks stood still for 6 hours, the phosphorus content in the water was tested for the second time, and the test data are sho...

Embodiment 2

[0043] (1) Take the water in the pond and put them into three large water tanks with the same capacity respectively. The hydraulic retention time of the pond is 12h, and the hydraulic load is 0.08m 3 / m 2 · d, the coverage of submerged plants at the bottom of the pond is 40%, respectively marked with A2, B2, and C2, and the phosphorus content in the water in the three cups of A2, B2, and C2 is detected first, and the detection data are shown in Table 2.

[0044] (2) pour the calcium carbonate of 30mm particle diameter into the A2 water tank, pour the calcium carbonate of 30mm particle diameter into the B2 water tank, pour the calcium carbonate of 30mm particle diameter into the C2 water tank, the coverage of calcium carbonate in the three water tanks Thickness is 90mm, stirring three tanks at the same time.

[0045] (3) After the three water tanks stood still for 6 hours, the phosphorus content in the water was tested for the second time, and the test data are shown in Table ...

Embodiment 3

[0049] (1) Take the water in the pond and put them into three large water tanks with the same capacity respectively. The hydraulic retention time of the pond is 12h, and the hydraulic load is 0.08m3 / m 2 · d, the coverage of submerged plants at the bottom of the pond is 40%, respectively marked with A3, B3, and C3, the first test is the phosphorus content of the water in the three cups of A3, B3, and C3 at this time, and the test data are shown in Table 3.

[0050] (2) pour the calcium carbonate of 30mm particle diameter into the A3 water tank, pour the calcium carbonate of 30mm particle diameter into the B3 water tank, pour the calcium carbonate of 30mm particle diameter into the C3 water tank, the coverage of calcium carbonate in the three water tanks Thickness is 100mm, stirring three tanks at the same time.

[0051] (3) After the three water tanks stood still for 6 hours, the phosphorus content in the water was tested for the second time, and the test data are shown in Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com