Yellow cover plate glass for photovoltaic building integration and preparation method thereof

A technology for photovoltaic buildings and cover glass, applied in the direction of coating, etc., can solve problems such as less obvious effect, lower conversion efficiency, and unsatisfactory color change effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

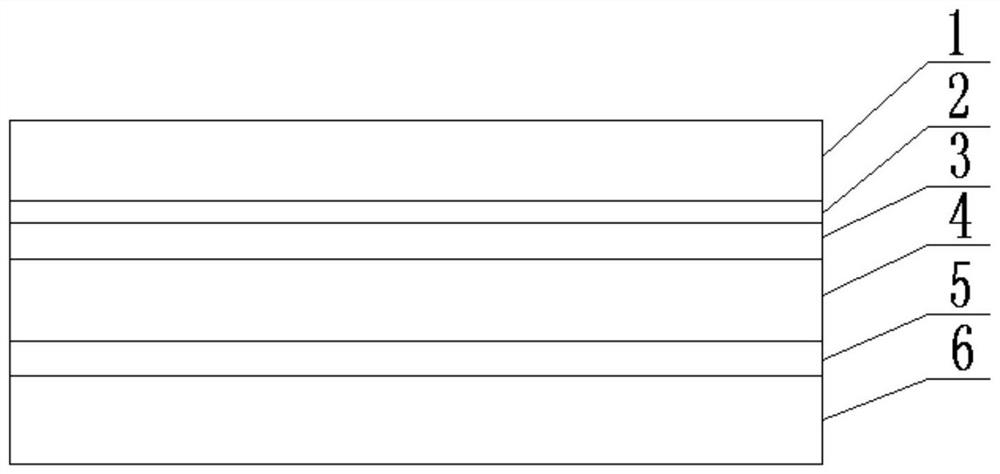

[0044] A yellow cover glass for photovoltaic building integration, which is composed of a glass substrate and a multilayer film interference color layer arranged from bottom to top; the glass substrate is ultra-clear glass with a thickness of 3.2 mm, and the multilayer film interference color layer is in order : glass / AZO74nm / SiAlO x 180nm / ZrO 2 15nm.

[0045] The preparation method is:

[0046] (1) Clean the glass substrate with ultrapure water, and set the line speed to 2.0m / min;

[0047] (2) After the glass substrate is pre-vacuumized, it is transferred into the coating chamber, and the background vacuum of the coating chamber is - 5 mbar, the magnetron sputtering coating equipment is installed with a Zn target doped with 2% Al by mass, the purity of argon gas is greater than 99.99%, the flow rate is 400 sccm, the purity of oxygen is greater than 99.99%, the flow rate is 1000 sccm, and the working pressure is 2-5× 10 -3 mbar, the total power of the target is set to 180...

Embodiment 2

[0052] A yellow cover glass for photovoltaic building integration, which is composed of a glass substrate and a multilayer film interference color layer arranged from bottom to top; the glass substrate is ultra-clear glass with a thickness of 3.2 mm, and the multilayer film interference color layer is in order : glass / SiAlN x (100nm) / SiAlO x (35nm) / SiAlN x (90nm) / SiAlO x (50nm).

[0053] The preparation method is:

[0054] (1) Clean the glass substrate with ultrapure water, and set the line speed to 2.0m / min;

[0055] (2) The glass substrate is transferred into the coating chamber after pre-vacuum transition. The magnetron sputtering coating equipment is equipped with a SiAl target, the Si / Al mass ratio is 9:1, and the purity of argon gas is greater than 99.99%, and the flow rate is 400 sccm. The purity of nitrogen is greater than 99.99%, the flow rate is 800sccm, and the working pressure is 2~5×10 -3 mbar, set the total power of the target to 240KW, and use the method o...

Embodiment 3

[0061] A yellow cover glass for photovoltaic building integration, which is composed of a glass substrate and a multilayer film interference color layer arranged from bottom to top; the glass substrate is ultra-clear embossed glass with a thickness of 6mm, and the multilayer film interference color layer is sequential For: glass / ZnSnO 2 (147nm) / SiO2 2 (20nm) / ZnSnO 2 (182nm).

[0062] The preparation method is:

[0063] (1) Clean the glass substrate with ultrapure water, and set the line speed to 1.0m / min;

[0064] (2) Transfer the glass substrate into the coating chamber after pre-vacuum transition, the background vacuum of the coating chamber is - 5 mbar, the magnetron sputtering coating equipment is equipped with ZnSn target, Zn / Sn is 1:1, the purity of argon gas is more than 99.99%, the flow rate is 400sccm, the purity of oxygen is more than 99.99%, the flow rate is 800sccm, and the working pressure is 2~5×10 -3 mbar, set the total power of the target to 150KW, and use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com