Carbon quantum dot, carbon quantum dot-titanium dioxide composite material and preparation method thereof

A technology of carbon quantum dots and titanium dioxide, applied in the field of photocatalytic materials, can solve problems such as complex purification steps and environmental hazards, and achieve good application prospects, good photocatalytic performance, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

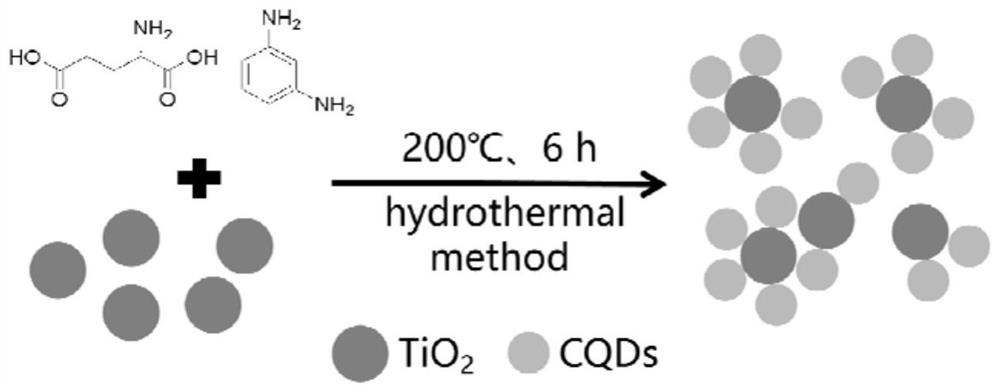

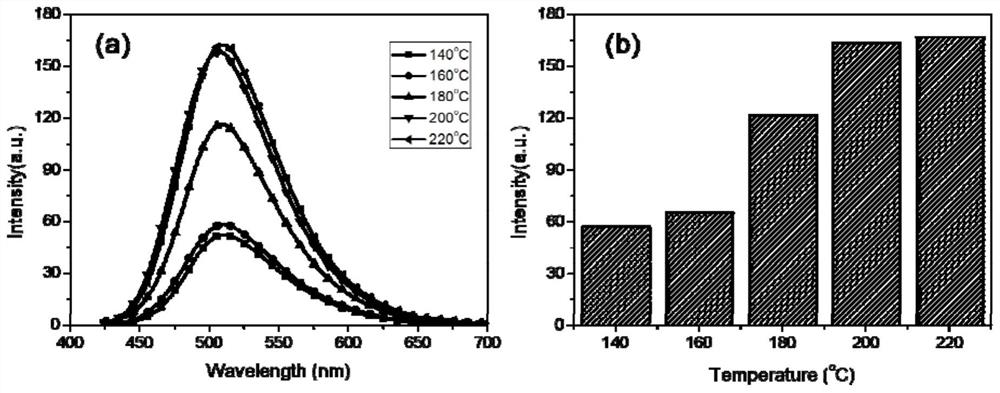

[0036] An embodiment of the present invention provides a method for preparing carbon quantum dots, which includes: mixing and dissolving a carbon source, phenylenediamine and water, and then performing a hydrothermal reaction. The inventors found that N-doped carbon quantum dots can be prepared by a one-step hydrothermal method using carbon source, phenylenediamine and water as raw materials, and the prepared carbon quantum dots have good fluorescence properties.

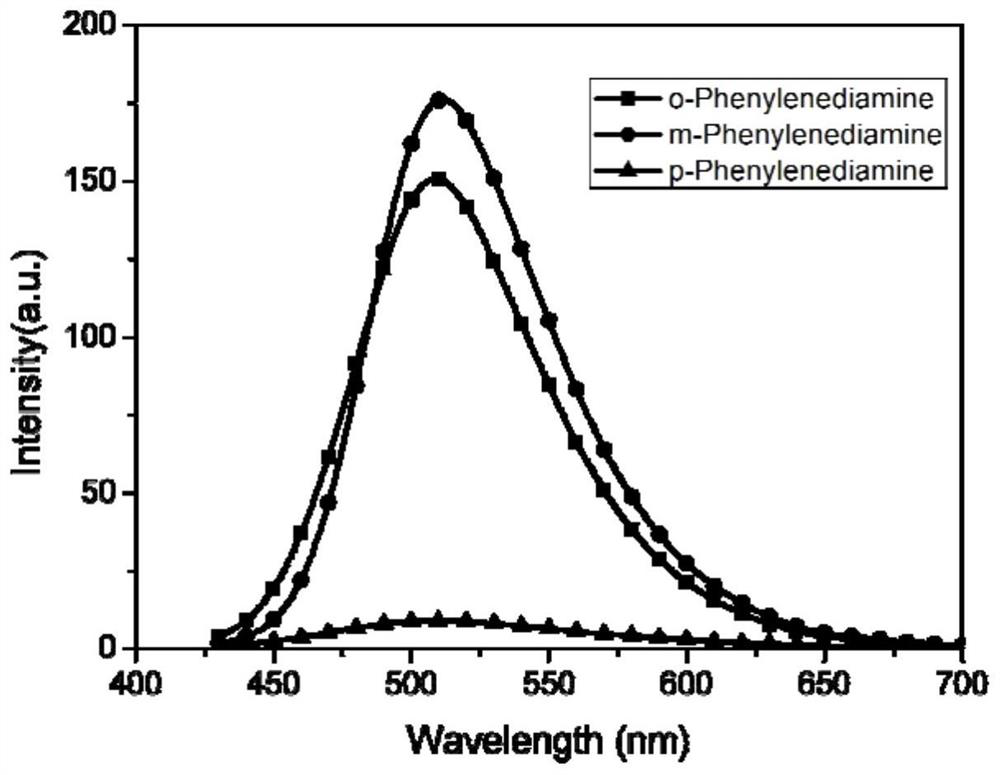

[0037] Specifically, the phenylenediamine is at least one selected from o-phenylenediamine, m-phenylenediamine and p-phenylenediamine; m-phenylenediamine is preferred. When m-phenylenediamine is used to control the surface groups of fluorescent carbon dots, the fluorescence performance of quantum dots is the best, which may be due to the fact that the two amino groups on m-phenylenediamine are more likely to combine with L-glutamic acid during the hydrothermal process. The two carboxyl groups undergo acylation react...

Embodiment 1

[0051] This embodiment provides a method for preparing carbon quantum dots, including:

[0052] Weigh 0.74g (0.005mol) of L-glutamic acid and 0.054g (0.0005mol) of o-phenylenediamine in a 50mL polytetrafluoroethylene reactor, add 20mL of deionized water to dissolve. After magnetic stirring for 30 min, the stirring bar was taken out and reacted in an oven at 200° C. for 6 h. After the reaction is completed, cool down to room temperature with the oven, and take out the stock solution of carbon quantum dots.

Embodiment 2

[0054] This embodiment provides a method for preparing carbon quantum dots, which differs from Embodiment 1 only in that o-phenylenediamine is replaced by m-phenylenediamine in equimolar amounts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com