Lubricating oil return filter with one-way valve

A one-way valve and lubricating oil technology, which is applied in the direction of engine lubrication, lubricating parts, engine components, etc., can solve the problems of inconvenient maintenance and control, failure to form a compression seal, and heavy weight, so as to reduce harmful risks and Less chance of damage and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below.

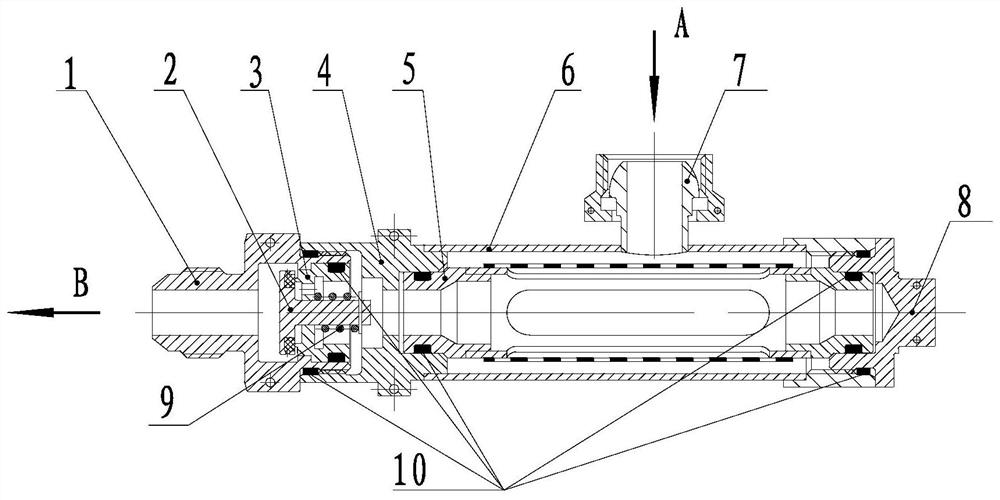

[0017] like figure 1 , The present invention proposes a design effect of the check valve with the return oil from the oil filter:

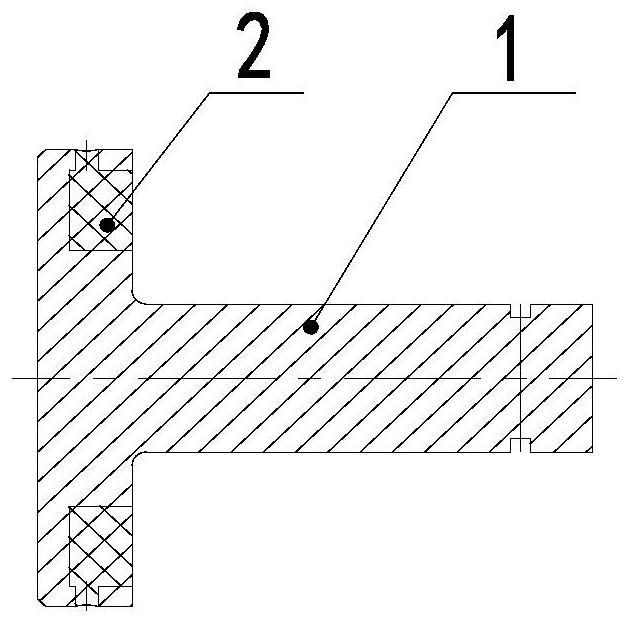

[0018] The mouthpiece mouthpiece with spherical surface, with the return line so as to better fit the installation, form-fit the spherical form of the nozzle pipe may be tapered to achieve a better sealing effect.

[0019] Design of the following steps:

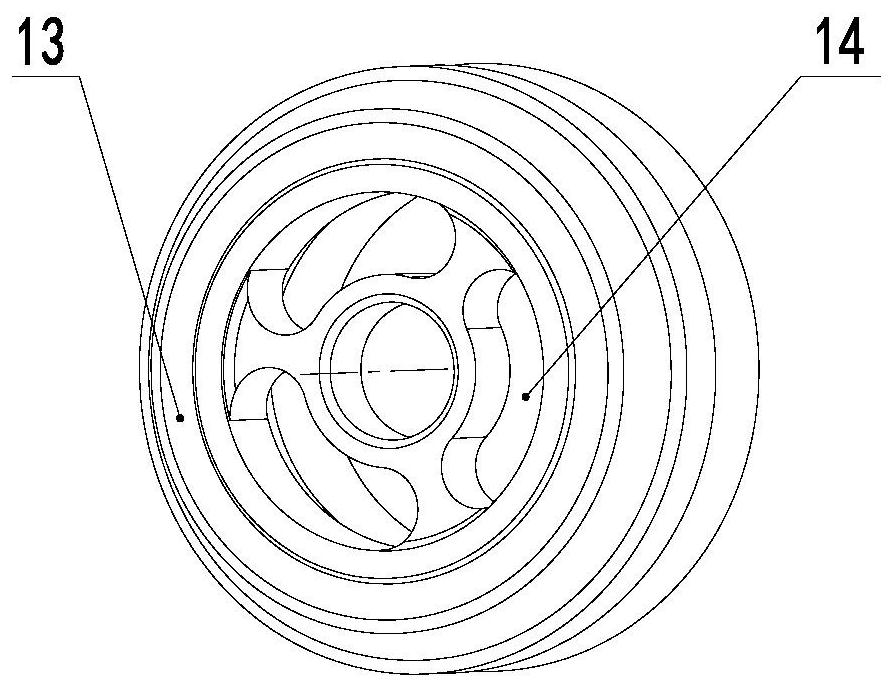

[0020] 1, the oil return oil filter design using one-way control valves. The system pressure back to the oil, the one-way valve opening pressure, a feedback control system since the shutter is formed; object simultaneously through the check valve assembly, valve seat and a filter in series, so that the oil is filtered to achieve oil flows in one direction;

[0021] 2, filter fixation with removable end cap design, washable meet the daily need for maintenance;

[0022] 3, valve seat seal uses a semicircular opening polishing stop limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com