Method for measuring gas acoustic relaxation absorption coefficient

A technology of absorption coefficient and measurement method, applied in measurement devices, complex mathematical operations, material analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the complex calculation and compensation process, difficult to meet the sensor accuracy, real-time and production cost requirements and other issues, to achieve the effect of reducing design complexity and cost, improving measurement accuracy, and simplifying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Measuring equipment can be placed in the gas to be tested, and the measuring equipment includes ultrasonic frequencies f 1 , f 2 and f 3Three sets of ultrasonic probes, barometers and thermocouples. Each set of ultrasonic probes includes an ultrasonic transmitting probe and an ultrasonic receiving probe.

[0036] Thermocouples are used to measure the temperature value of the gas to be measured;

[0037] The barometer is used to measure the pressure value of the gas to be tested;

[0038] Three pairs of ultrasonic probes are used to measure the ultrasonic frequency f 1 , f 2 and f 3 The sound velocity value of the ultrasonic wave in the gas to be measured is to obtain the acoustic measurement value, which is used to synthesize the acoustic relaxation absorption spectrum.

[0039] Ultrasonic frequency f 1 , f 2 and f 3 The gas can be set according to the gas type and the measured pressure range. For example, for CH 4 , CO 2 、CL 2 Equally strong relaxation ca...

Embodiment 2

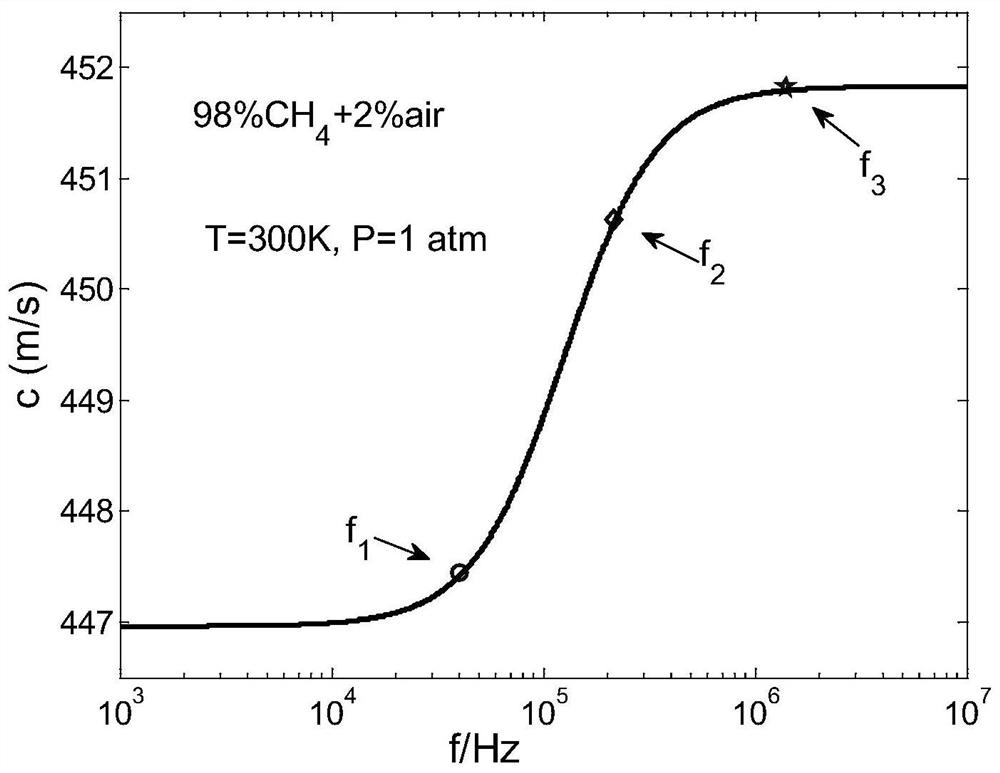

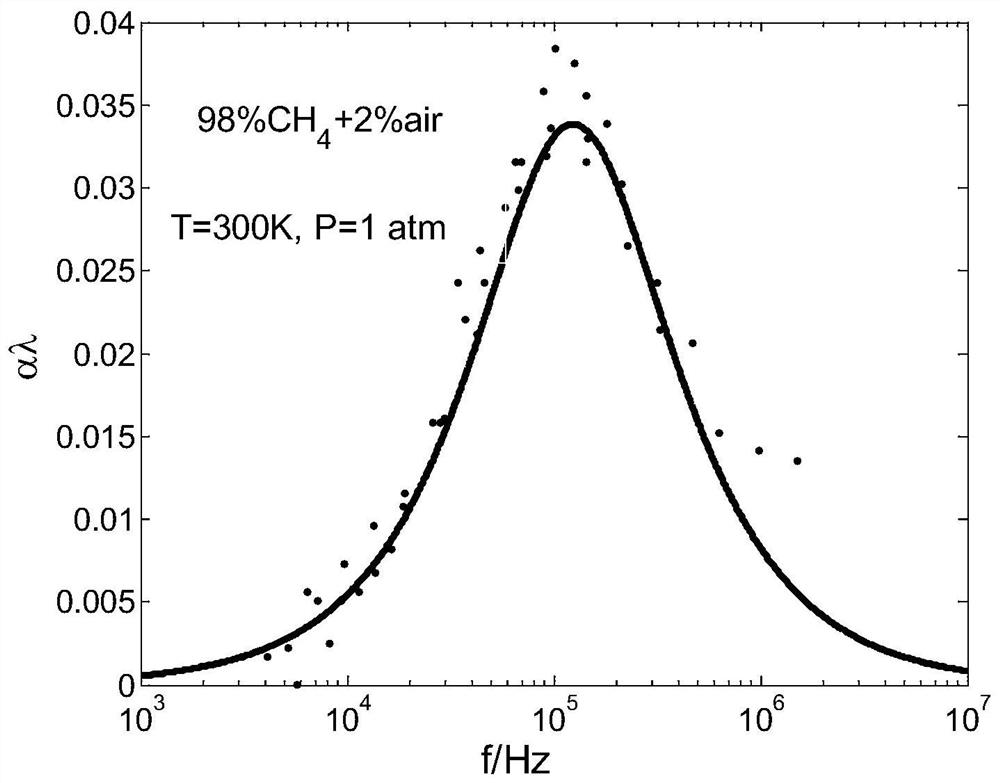

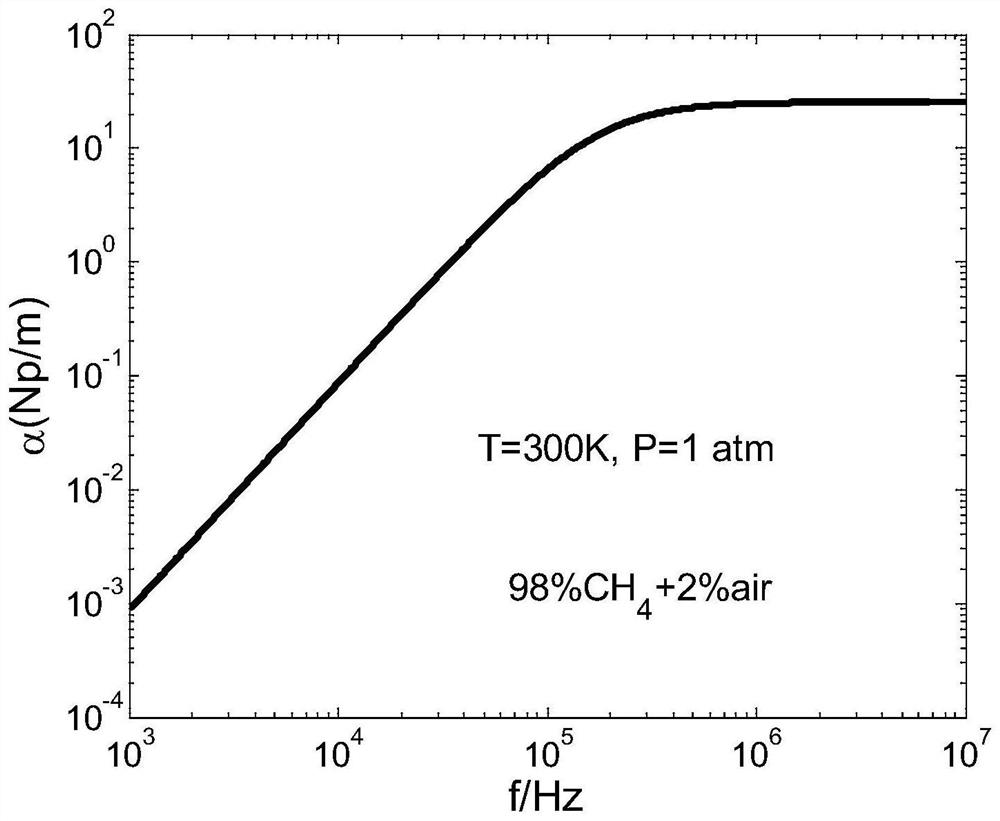

[0062] In the present embodiment, the method of embodiment 1 is utilized: when the gas to be measured is 98% CH 4 -2% air, at three frequency points f 1 = 40kHz, f 2 = 215kHz, f 3 =1.4, the measured sound velocity is c(f 1 )=447.446m / s,c(f 2 )=450.626m / s and c(f 3 )=451.831m / s; the ambient temperature T=300K measured by the thermocouple; the pressure P=1atm measured by the barometer.

[0063] The relaxation intensity ε=0.0213 obtained by formula (7) is calculated, and then the relaxation frequency f is calculated by formula (8) m =1.241×10 5 Hz, and the absorption maximum μ calculated by formula (3) m = 0.0339. Then, based on the calculated f m , μ m and ε: Using formula (2), the sound velocity dispersion spectrum c(f) can be reconstructed (see figure 1 ); use formula (1) to reconstruct the acoustic relaxation absorption spectrum μ(f) (see figure 2 ); use (9) to reconstruct the frequency-dependent acoustic relaxation absorption coefficient (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com