Cesium-tin-iodine film as well as preparation method and application thereof

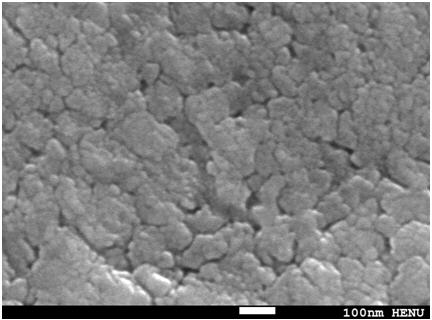

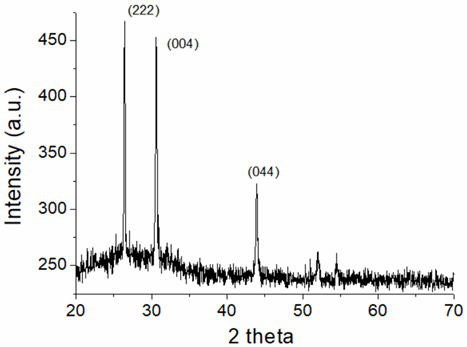

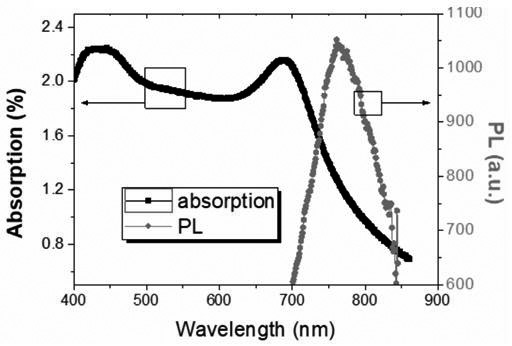

A thin-film, solution-based technology, applied in the field of perovskite photodetectors, achieves the effects of smooth and dense surface, high absorption intensity, and high phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of solution method prepares cesium tin iodide (Cs 2 SnI 6 ) thin film method comprising the steps of:

[0028] (1) Weigh 117mg of cesium iodide and 282mg of tin iodide, add 0.5ml of mixed solvent of DMSO and DMF (the volume ratio of DMSO and DMF is 3:1), stir at 60°C and 1000 rpm Dissolved and made into 0.45mol / L Cs 2 SnI 6 The precursor solution;

[0029] (2) Place the solution prepared in step (1) under a nitrogen atmosphere for 7 days to age;

[0030] (3) Use a pipette gun to take 60 μL of the aged solution and drop it on a clean FTO glass substrate (1.6mm*1.8mm), and prepare Cs by spin coating 2SnI 6 Film, specifically, the rotation speed of the first stage is 1000 rpm, and the time is 10 seconds; the rotation speed of the second stage is 2500 rpm, and the time is 60 seconds; 200 µl isopropanol. Then place the substrate on a hot stage with a temperature of 50° C. and heat it for 20 minutes;

[0031] (4) After the substrate is naturally cooled to room...

Embodiment 2

[0036] A kind of solution method prepares cesium tin iodide (Cs 2 SnI 6 ) thin film method comprising the steps of:

[0037] (1) Weigh 468mg of cesium iodide and 564mg of tin iodide, add 1.0ml of DMSO and DMF mixed solution (the volume ratio of DMSO and DMF is 1:0), stir and dissolve at 60 degrees Celsius and 1000 rpm , dubbed 0.9mol / L Cs 2 SnI 6 The precursor solution;

[0038] (2) Place the solution prepared in step (1) at room temperature for 30 days;

[0039] (3) Use a pipette gun to take 60 μL of the aged solution and drop it on a clean FTO glass substrate (1.6mm*1.8mm), and prepare Cs by spin coating 2 SnI 6 Film, specifically, the rotation speed of the first stage is 1000 rev / min, and the time is 10 seconds; 200 µl isopropanol. Then place the substrate on a hot stage with a temperature of 30° C. and heat it for 40 minutes;

[0040] (4) After the substrate is naturally cooled to room temperature, 100 microliters of 10 mg / ml tin iodide isopropanol solution is dro...

Embodiment 3

[0043] A kind of solution method prepares cesium tin iodide (Cs 2 SnI 6 ) thin film method comprising the steps of:

[0044] (1) Weigh 117mg of cesium iodide and 564mg of tin iodide, add 1.0ml of DMSO and DMF mixed solution (the volume ratio of DMSO and DMF is 6:1), stir and dissolve at 60°C and 1000 rpm , dubbed 0.225mol / L of Cs 2 SnI 6 The precursor solution;

[0045] (2) Place the solution prepared in step (1) at room temperature for 4 days;

[0046] (3) Use a pipette gun to take 60 μL of the aged solution and drop it on a clean FTO glass substrate (1.6mm*1.8mm), and prepare Cs by spin coating 2 SnI 6 Film, specifically, the rotation speed of the first stage is 1000 rev / min, and the time is 10 seconds; 500 µl isopropanol. Then place the substrate on a hot stage with a temperature of 70° C. and heat it for 1 minute;

[0047] (4) After the substrate is naturally cooled to room temperature, 40 microliters of 1mg / ml tin iodide isopropanol solution is dropped on it, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com