A kind of preparation method and application of epoxidation reaction catalyst

An epoxidation reaction and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve problems such as complex products, achieve environmental friendliness, improve stability, and reduce raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

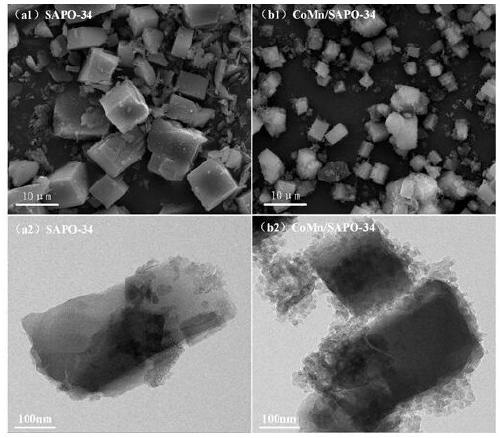

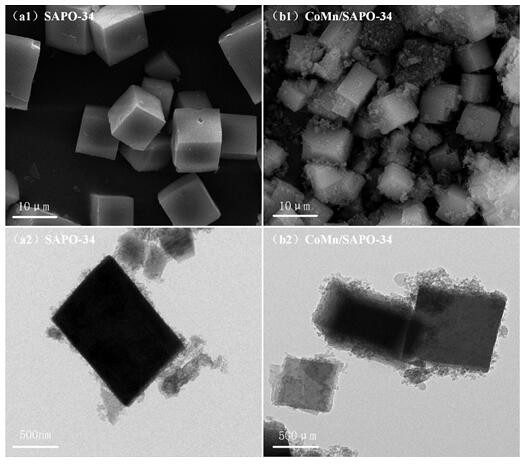

Image

Examples

Embodiment 1

[0026] (1) Press Al 2 o 3 :P 2 o 5 :SiO2 2 :TEAOH:H 2 O mol ratio is the ratio of 1:1:0.6:2:80, and the corresponding reaction raw material of taking above-mentioned substance is pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, deionized water; Pseudoboehmite was dissolved in deionized water and stirred until uniform, then orthophosphoric acid and silica sol were added dropwise in sequence, after thorough stirring, tetraethylammonium hydroxide was added as a template agent, the pH was adjusted to 8.3, and the initial gel mixture was obtained by stirring ;

[0027] (2) Put the initial gel mixture in step (1) into the crystallization kettle of polytetrafluoroethylene in the inner village, and after aging for 24 hours, crystallize at a crystallization temperature of 180°C for 120 hours;

[0028] (3) After the crystallization is completed, filter, wash with deionized water, wash with ethanol, and dry at 110°C for 5 hours, then raise the temper...

Embodiment 2

[0032] (1) Press Al 2 o 3 :P 2 o 5 :SiO2 2 :TEAOH:H 2 O mol ratio is the ratio of 1:1:0.2:3:80, and the corresponding reaction raw material of taking above-mentioned substance is pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, deionized water; Pseudoboehmite was dissolved in deionized water and stirred until uniform, then orthophosphoric acid and silica sol were added dropwise in sequence, after thorough stirring, tetraethylammonium hydroxide was added as a template agent, the pH was adjusted to 5.5, and the initial gel mixture was obtained by stirring ;

[0033] (2) Put the initial gel mixture in step (1) into the crystallization kettle of polytetrafluoroethylene in the inner village, and after aging for 3 hours, crystallize at the crystallization temperature of 210°C for 60 hours;

[0034] (3) After the crystallization is completed, filter, wash with deionized water, wash with ethanol, and dry at 110°C for 5 hours, raise the temperature...

Embodiment 3

[0038] (1) Press Al 2 o 3 :P 2 o 5 :SiO2 2 :TEAOH:H 2 O mol ratio is the ratio of 1:1:0.8:1:80, and the corresponding reaction raw material of taking above-mentioned substance is pseudo-boehmite, orthophosphoric acid, silica sol, tetraethylammonium hydroxide, deionized water; Pseudo-boehmite was dissolved in deionized water and stirred until uniform, then orthophosphoric acid and silica sol were added dropwise in sequence, after thorough stirring, tetraethylammonium hydroxide was added as a template agent, the pH was adjusted to 10, and the initial gel mixture was obtained by stirring ;

[0039] (2) Put the initial gel mixture in step (1) into the crystallization kettle of polytetrafluoroethylene in the inner village, and after aging for 36 hours, crystallize at the crystallization temperature of 200°C for 18 hours;

[0040] (3) After the crystallization is completed, filter, wash with deionized water, wash with ethanol, and dry at 110°C for 5 hours, then raise the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com