A method for photoelectrocatalytic splitting of water to produce hydrogen

A technology for photoelectric catalysis and water splitting, which is applied in the directions of electrolysis components, electrolysis process, electrodes, etc., to achieve the effect of wide preparation window, wide application prospect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

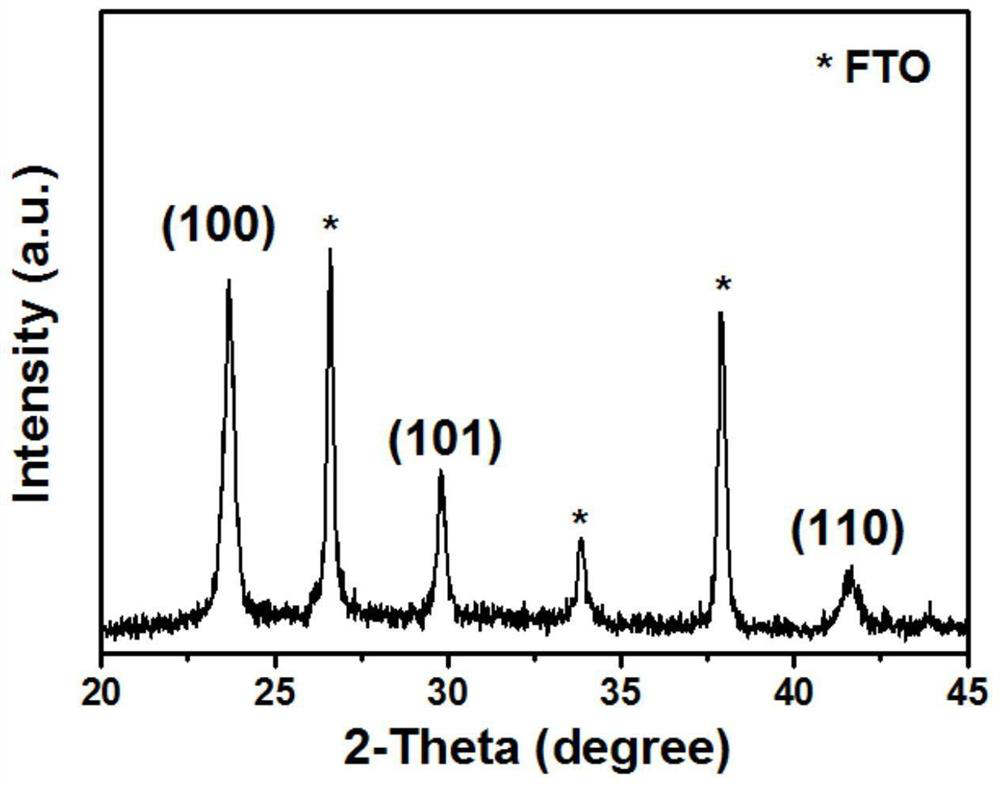

[0021] Divide 2.5×2.5cm 2 The FTO glass was ultrasonically cleaned with ethanol, acetone, and ultrapure water for 30 min respectively, and dried with nitrogen to obtain a cleaned FTO glass sheet; Se thin film, the vacuum degree of the controlled thermal evaporation system chamber is 5×10 -3 Pa; and then performing rapid thermal annealing treatment on the deposited Se thin film, the temperature of the rapid annealing treatment is 180° C., and the time is 5 minutes to obtain the Se / FTO photocathode. The crystallinity of the Se thin film on the photocathode is as follows figure 1 shown. In the figure, the XRD diffraction peaks of 2θ at 23.1°, 29.4°, and 41.7° correspond to the (100), (101), and (110) crystal orientations of Se respectively, indicating that gray-black t-Se (triangular structure-Se ).

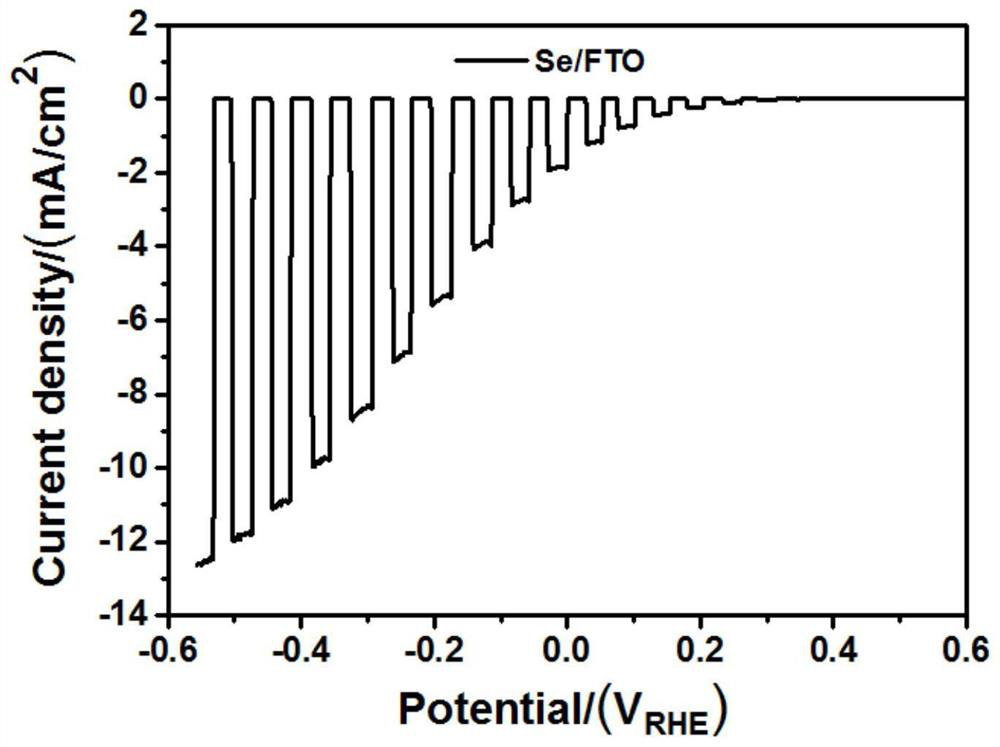

[0022] The prepared Se / FTO photocathode was used as the working electrode, with 0.5mol / LH 2 SO 4The aqueous solution is the electrolyte solution, the saturated calomel electro...

Embodiment 2

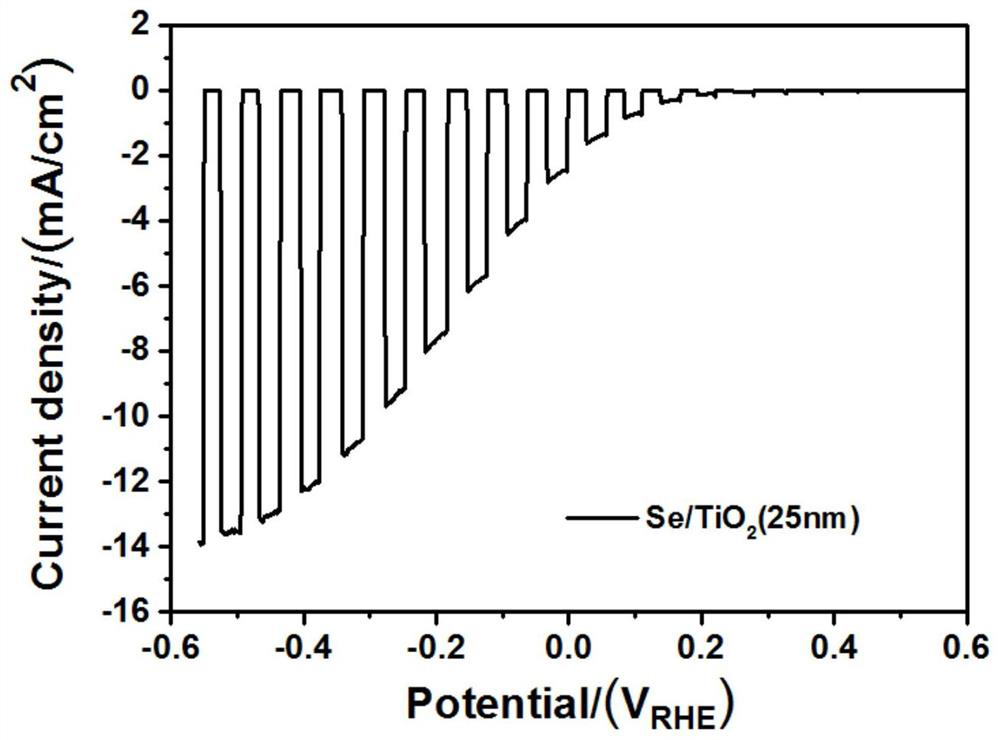

[0024] In this example, the Se / FTO photocathode is first prepared according to the method of Example 1, and then a layer of TiO with a thickness of 25 nm is deposited on the surface of the Se film of the Se / FTO photocathode by atomic layer deposition. 2 Thin film, the chamber substrate temperature is 120°C, and the preparation cycle is 4 cycles to obtain TiO 2 / Se / FTO photocathode. The prepared TiO 2 / Se / FTO photocathode as working electrode, with 0.5mol / L H 2 SO 4 The aqueous solution is the electrolyte, and the saturated calomel electrode and the platinum sheet are used as the reference electrode and the counter electrode respectively, and the simulated sunlight composed of a 300W xenon lamp and an AM 1.5G filter is used as the light source at a light intensity of 100mW / cm 2 The photocathode activity (LSV) test of continuous chopping light is carried out, and the test pattern is as follows image 3 shown. The results show that at 25nm TiO 2 The coated Se electrode is a...

Embodiment 3

[0026] In the present embodiment, first prepare TiO according to the method of embodiment 2 2 / Se / FTO photocathode followed by TiO 2 TiO / Se / FTO photocathode 2 The surface of the film was again sputtered with Pt as a hydrogen catalyst by means of magnetron sputtering, and the vacuum degree of the system was 5×10 - 3 Pa, sputtering power is 40W, sputtering time is 6s, get Pt / TiO 2 / Se / FTO photocathode. The prepared Pt / TiO 2 / Se / FTO photocathode as working electrode, with 0.5mol / LH 2 SO 4 The aqueous solution is the electrolyte, and the saturated calomel electrode and the platinum sheet are used as the reference electrode and the counter electrode respectively, and the simulated sunlight composed of a xenon lamp with a light source of 300W and an AM 1.5G filter is used at a light intensity of 100mW / cm 2 The photocathode activity (LSV) test under continuous chopping light, the test results are as follows Figure 4 shown. The results show that in TiO 2 The surface is furt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com