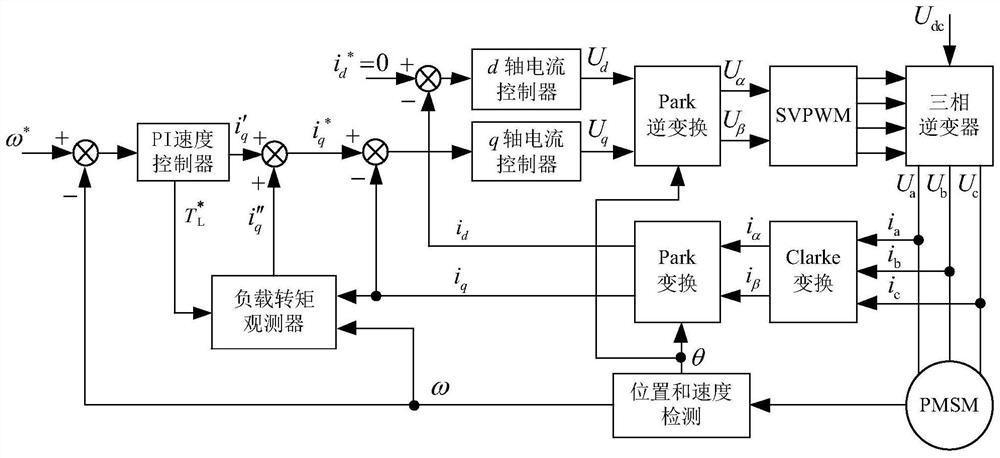

Drive control system of permanent magnet synchronous motor of numerically-controlled machine tool

A permanent magnet synchronous motor, drive control technology, applied in the control system, vector control system, motor generator control, etc. Major and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

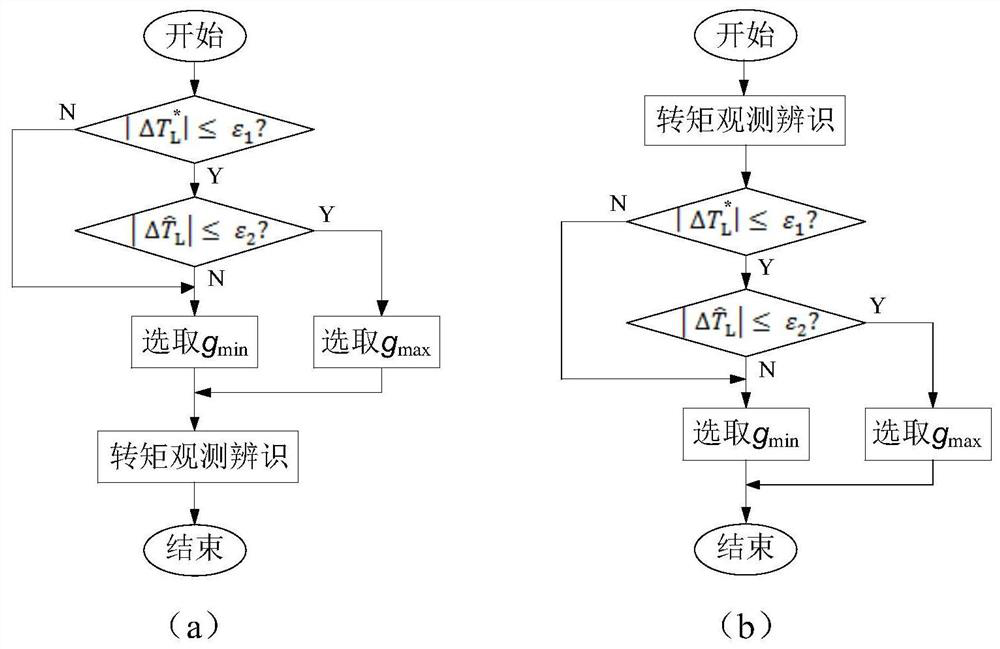

Embodiment 1

[0071] In formula (7), is the observed value of the load torque, is the rotor angular velocity estimate, g is the feedback gain of the load torque observer, k g is the sliding mode gain of the load torque observer embodiment 1, and the load torque observer embodiment 1 is a sliding mode observer. Compared with the load torque, the motor friction has a small proportion, so that B=0, ignoring the influence of friction, then the load torque observer embodiment 1 of formula (7) becomes:

[0072]

[0073] According to (6) and formula (8) when B=0, obtain the error equation of load torque observer embodiment 1 as:

[0074]

[0075] In formula (9), is the rotor angular velocity estimation error, Observing the error for the load torque, and defining the sliding surface of the observer as According to the sliding mode accessibility condition, the stability condition of the observer system in formula (8) is k g ≤-|e 2 / J|, and g<0.

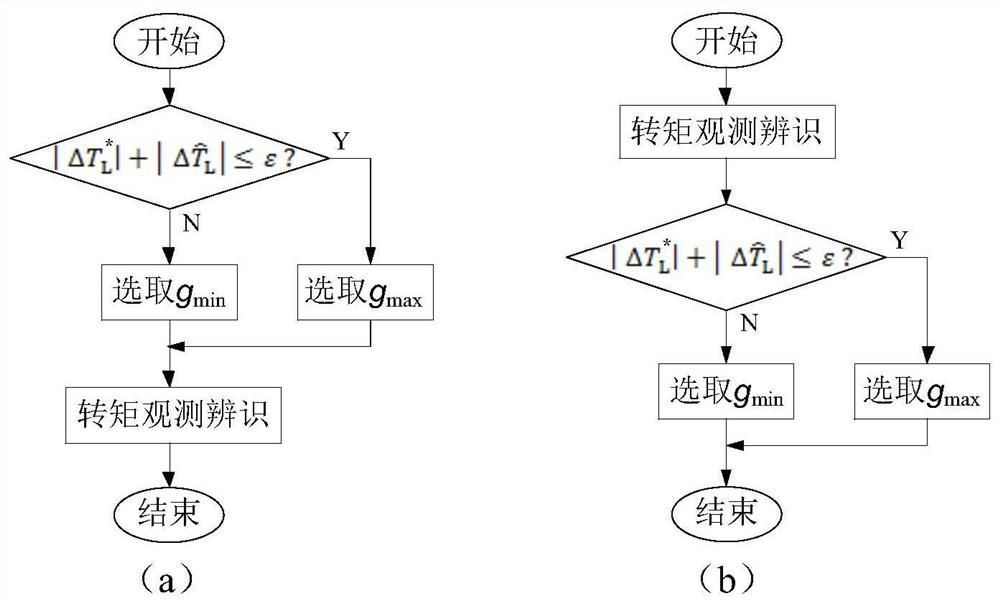

Embodiment 2

[0078] Compared with the load torque, the motor friction has a small proportion, so that B=0, ignoring the influence of friction, then the load torque observer embodiment 2 of formula (10) becomes:

[0079]

[0080] In formula (10), (11), is the observed value of the load torque, is the rotor angular velocity estimate, g is the feedback gain of the load torque observer, k W is the proportional gain of the load torque observer embodiment 2, and the load torque observer embodiment 2 is a state observer. According to the formula (6) and formula (11) when B=0, the error equation of the load torque observer embodiment 2 is obtained as:

[0081]

[0082] In formula (12), is the rotor angular velocity estimation error, is the load torque observation error. The state observer of formula (11) is an autonomous linear system, at k W <0, and g<0, the observer is asymptotically stable. The formula (7) of the load torque observer embodiment 1 and the formula (10) of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com