Multi-station ball milling mechanism for neodymium iron boron waste recovery and implementation method thereof

A waste recycling, NdFeB technology, applied in grain processing and other directions, can solve the problems of low pulverization degree, poor pulverization quality, affecting work efficiency, etc., and achieve the effect of obvious pulverizing effect, improving pulverizing quality, and improving resource utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

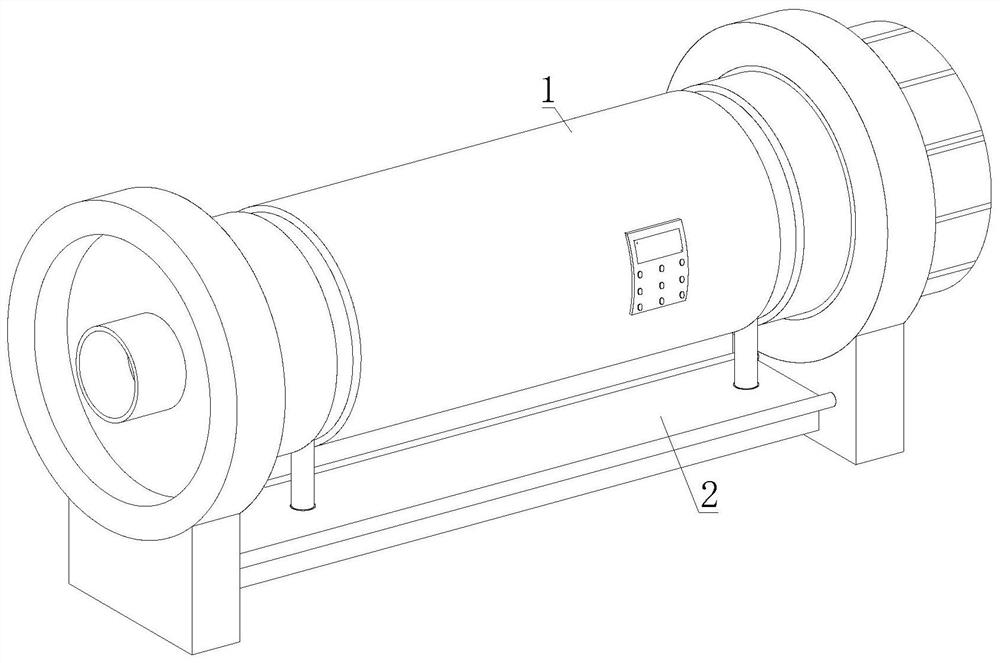

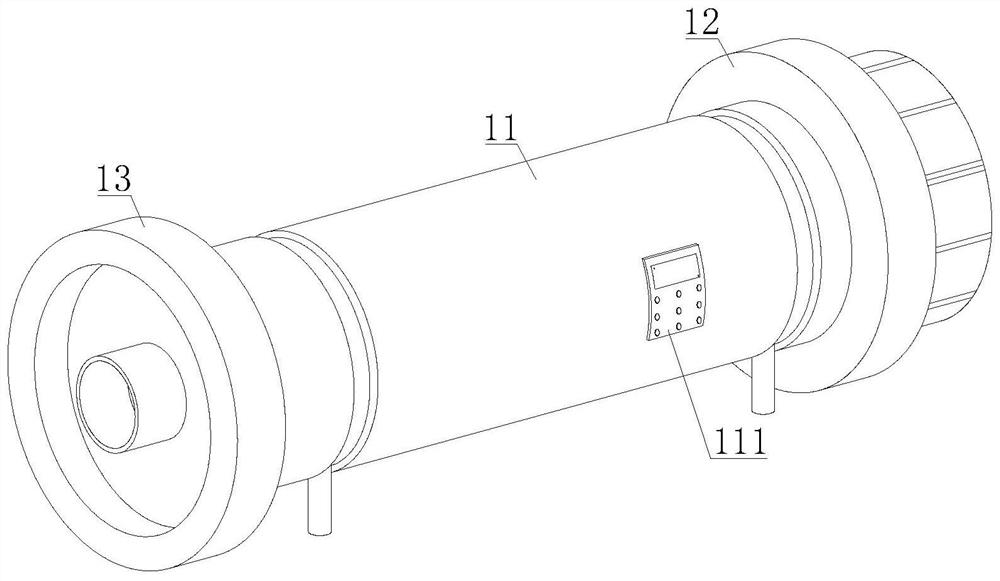

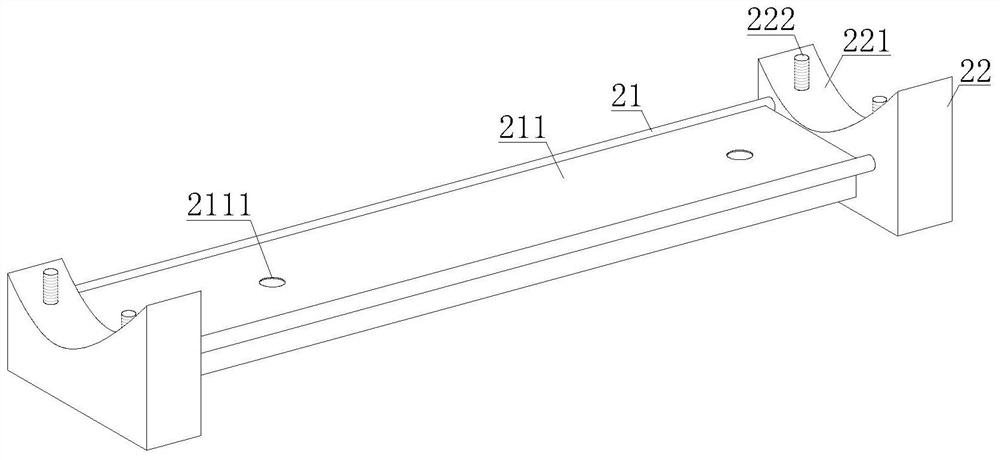

[0037] refer to Figure 1-3 , a multi-station ball milling mechanism for NdFeB waste recycling, comprising a main body 1 and a support mechanism 2, the upper end of the support mechanism 2 is provided with a main body 1, the main body 1 includes a main cylinder 11, a power mechanism 12 and a feeding Mechanism 13, one end of the main cylinder 11 is fixedly equipped with a power mechanism 12, the other end of the main cylinder 11 is provided with a feeding mechanism 13, the lower end of the main cylinder 11 is provided with a support mechanism 2, and the support mechanism 2 includes a connecting rod 21 and Riser 22, the two ends of connecting rod 21 are all fixedly installed with riser 22, and riser 22 is connected with power mechanism 12 and feeding mechanism 13.

Embodiment 2

[0039] refer to figure 2 , 4 , 5, 8 and 10, the main cylinder 11 includes a control panel 111, a rotary groove 112, a movable rod 113, an extrusion mechanism 114, a triangular groove 115 and a protective wall 116, and the control panel 111 is fixedly installed on the outer surface of the main cylinder 11 Above, the outer surface of the main cylinder 11 is provided with a turning groove 112, and the inside of the turning groove 112 is provided with a movable rod 113, and the movable rod 113 is movably connected with the turning groove 112, and the inside of the main cylinder 11 is provided with an extrusion mechanism 114 , the inner wall of the main cylinder 11 is provided with a triangular groove 115, and the protective wall 116 is arranged on the inner wall of the main cylinder 11. The main cylinder 11 also includes a crushing degree module 117, a heater 118, a temperature sensing module 119, a liquid level The sensing module 11A and the speed sensing module 11B, the crushi...

Embodiment 3

[0041] refer to Figure 4 The power mechanism 12 includes an electromechanical box 121, a mounting plate 122 and a rotating shaft 123. One side of the mounting plate 122 is provided with an electromechanical box 121, and the other side of the mounting plate 122 is provided with a rotating shaft 123. One end of the rotating shaft 123 passes through the mounting plate 122 and the rotating shaft 123. The output end of the internal motor of the electromechanical box 121 is connected, the other end of the rotating shaft 123 is connected with the main cylinder 11, the feeding mechanism 13 includes a connecting flange 131 and a feeding pipe 132, and one side of the connecting flange 131 is provided with a feeding The pipe 132 , the feeding pipe 132 passes through the connecting flange 131 and communicates with the main cylinder 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com