Manufacturing process of laminated film mold

A manufacturing process and a laminating technology, which is applied in the manufacturing process of laminating film molds, can solve the problems of affecting the product accuracy and the service life of the texture master, affecting the texture adhesion, and low screen printing accuracy, so as to achieve the appearance of The effect of high yield, short working time and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention, but this does not limit the protection scope of the present invention.

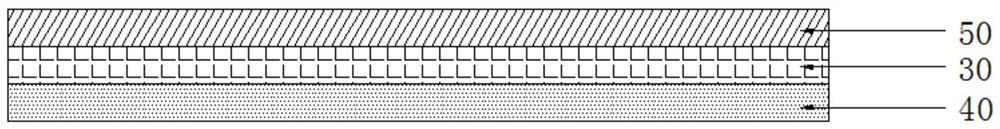

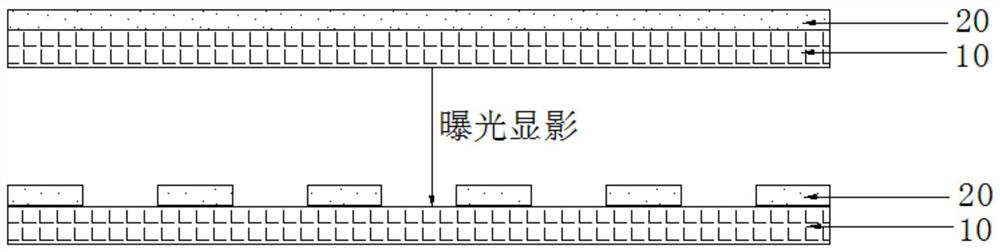

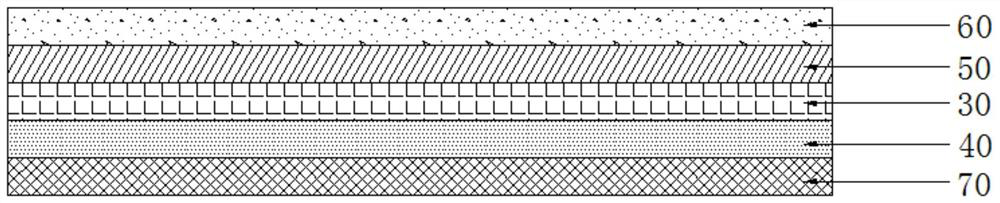

[0026] see Figure 1~3 , the present invention provides a manufacturing process of a laminated film mold. The present invention uses exposure and development methods to make the required pattern on the film film; transfer the texture on the texture master mold to the PET film through the transfer process and aging treatment to obtain a PET textured film; then the film film and the PET textured film are laminated and defoamed to form a bonded film mold.

[0027] The scheme of the present invention will be described in detail below in conjunction with specific embodiments:

[0028] The manufacturing process of the bonding type film mold of the present invention comprises the following steps:

[0029] S1. Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com