Phosphorylated chitosan derivative as well as preparation method and application thereof

A technology of phosphorylated chitosan and derivatives, which is applied in chemical instruments and methods, wastewater treatment in processing, water/sludge/sewage treatment, etc., can solve problems such as reagent toxicity, complicated operation, and human health damage, and achieve The preparation process is simple, the preparation efficiency is high, and the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

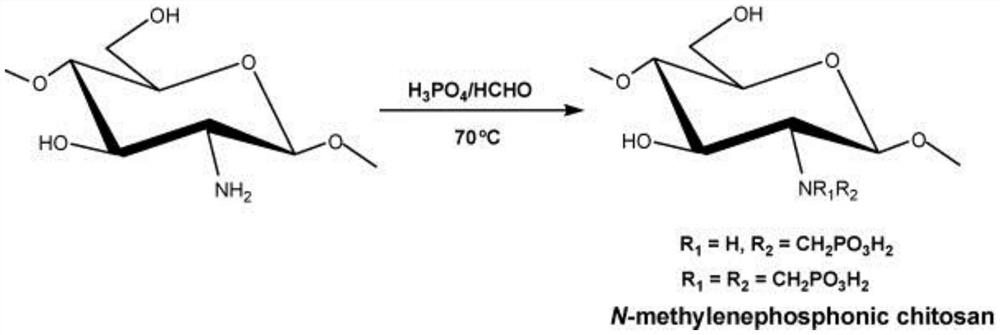

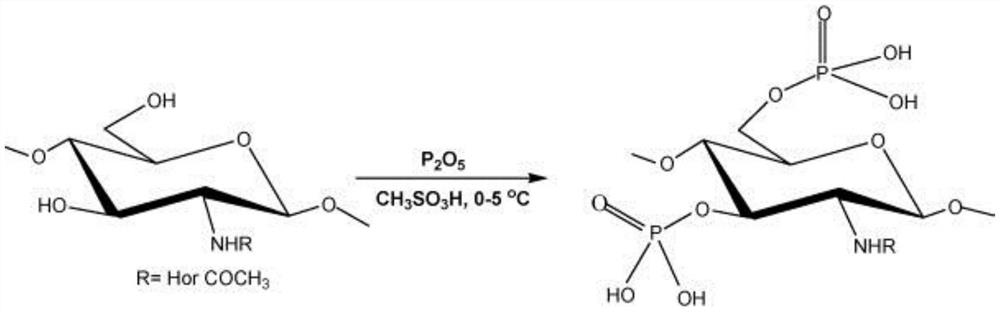

Method used

Image

Examples

Embodiment 1

[0053] A kind of synthetic method of phosphorylated chitosan derivative, this method comprises the following steps:

[0054] Step (1): In a three-necked flask equipped with a stirrer, add 1.0g (4.4×10 -3 mol) chitosan (solid content is 80%, deacetylation degree is 75%), 20ml deionized water, 0.5ml pure acetic acid, is made into the solution that concentration is 4%, and reaction mixture is fully stirred until chitosan dissolves completely.

[0055] Step (2): in the there-necked flask that stirrer is equipped with, add 4.75g (8.8 * 10 -3 mol) PBTCA, 1.6ml mass concentration is slowly added dropwise in ice water and is 50% NaOH solution, adjusts pH to be 4; Add 2.57g (1.32×10 -2 mol) EDC, adding 6ml concentration of 95% ethanol, stirred to make it fully dissolved, transferred to a three-necked flask and reacted with PBTCA at room temperature for 5min; then added 0.335g (1.32×10 -2 mol) imidazole, add 6ml of deionized water, stir to make it fully dissolved, and transfer to a th...

Embodiment 2

[0063] A kind of synthetic method of phosphorylated chitosan derivative, this method comprises the following steps:

[0064] Step (1): In a three-necked flask equipped with a stirrer, add 1.0g (4.4×10 -3 mol) chitosan (solid content is 80%, deacetylation degree is 85%), 27ml deionized water, 0.1ml dilute HCl solution (concentration is 0.2mol / L), is made into the solution that concentration is 3%, reaction mixture Stir well until the chitosan is completely dissolved.

[0065] Step (2): In a three-necked flask equipped with a stirrer, add 5.35g (9.9×10 -3 mol) PBTCA, 2.0ml mass concentration is slowly added dropwise in ice water and is the KOH solution of 50%, and the adjustment pH value is 4; Then add 2.57g (1.32×10 -2 mol) EDC, adding 8ml concentration of 95% ethanol, stirred to make it fully dissolved, transferred to a three-necked flask to react with PBTCA for 6min; then added 0.90g (1.32×10 -2 mol) imidazole, add 8ml of deionized water, stir to make it fully dissolved, a...

Embodiment 3

[0073] A kind of synthetic method of phosphorylated chitosan derivative, this method comprises the following steps:

[0074] Step (1): In a three-necked flask equipped with a stirrer, add 1.0g (4.4×10 -3 mol) chitosan (solid content is 80%, deacetylation degree is 80%), 16ml deionized water, 0.1ml dilute H 2 SO 4 Solution (concentration is 0.2mol / L), is made into the solution that concentration is 5%, and reaction mixture is fully stirred until chitosan dissolves completely.

[0075] Step (2): in the there-necked flask that stirrer is equipped with, add 7.13g (1.32 * 10 -2 mol) PBTCA, slowly add 2.5ml mass concentration dropwise in ice water and be the triethanolamine of 50%, adjust the pH value to be 5; Then add 3.43g (1.76×10 -2 mol) EDC, adding 8ml concentration of 95% ethanol, stirring to make it fully dissolved, transferred to a three-necked flask to react with PBTCA for 7min; add 1.21g (1.76×10 -2 mol) imidazole, add 8ml of deionized water, stir to make it fully diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com