Preparation method and use method of three-in-one oily solvent additive with antibacterial zinc ions

An oily solvent and three-in-one technology, which is applied in the field of preparation of three-in-one oily solvent additives, can solve problems such as the limitation of the use range of nano-molecular water, and achieve the effects of improving immunity, adjusting autonomic nerves, and purifying blood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the three-in-one oily solvent additive with antibacterial zinc ions is characterized in that it comprises the steps:

[0026] Step 1, water is used as the carrier, and the water carrier is treated by RO reverse osmosis and O 3 After being sterilized with ultraviolet light, it turns into water vapor when heated to 100-130 degrees and boiled;

[0027] Step 2, let the small water molecules of water vapor surround the particles produced by the 20-30 nanometer porous material, and obtain the aqueous solution after condensing through the condenser. The nanoporous material includes: SiO 2 、TiO 2 、Al 2 o 3 , Fe 2 o 3 , FeO, B 2 o 3 And rare earth and three-dimensional granular zeolite, the weight ratio of its raw materials is: 0.43-0.48: 0.08-0.12: 0.06-0.10: 0.04-0.08: 0.04-0.08: 0.04-0.08: 0.08-0.12: 0.06-0.10, preferably SiO 2 、TiO 2 、Al 2 o 3 , Fe 2 o 3 , FeO, B 2 o 3 , rare earth and three-dimensional granular zeolite, the weight ra...

specific Embodiment 1

[0034] Use the above-mentioned preparation method of the three-in-one oily solvent additive with antibacterial zinc ion to prepare the three-in-one oily solvent additive, in step 5, the aqueous solution and C 3 h 8 o 2 The mixing ratio is 1:1, and then complete the following operations:

[0035] S1, blend the three-in-one oil-based solvent additive with the oil-based paint until the pH value is between 7-8, and then blend with the oil-based paint to make an environmentally friendly paint. The amount of the three-in-one oil-based solvent additive accounts for 30% of the oil-based paint %;

[0036] S2, the environmentally friendly paint is evenly stirred and then painted onto the color steel;

[0037] S3, painted color steel is baked at 480 degrees Celsius and then cooled;

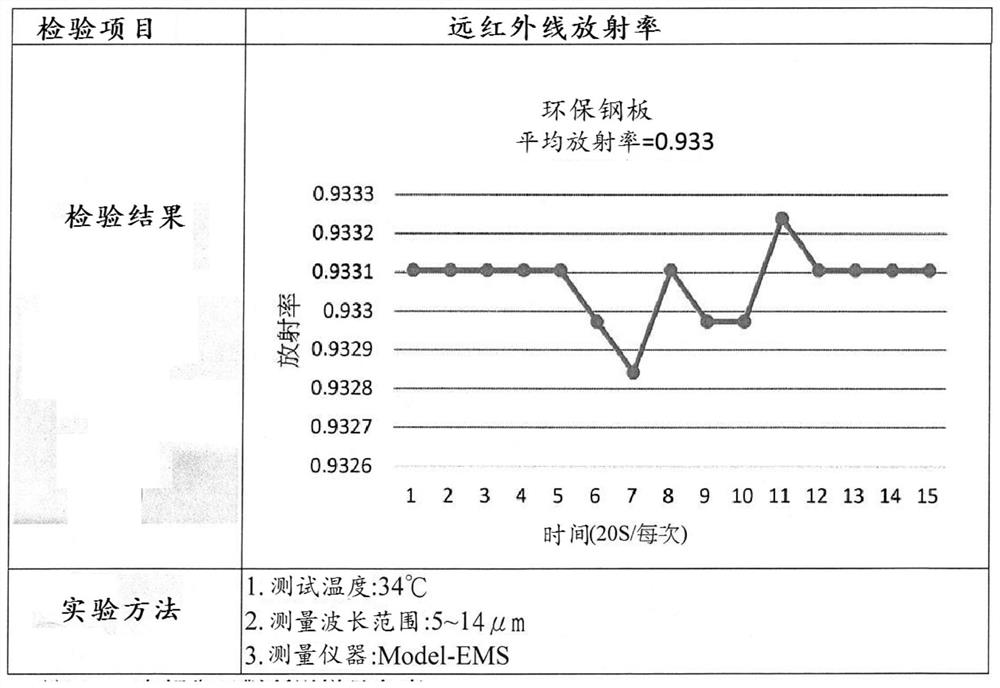

[0038] S4, the color difference and gloss are tested and the results are obtained. Compared with the original paint, the color difference and gloss are both within the allowable range, and an environment...

specific Embodiment 2

[0048] Use the above-mentioned preparation method of the three-in-one oily solvent additive with antibacterial zinc ions to prepare the three-in-one oily solvent additive, blend the three-in-one oily solvent additive with epoxy resin, and the addition amount of the three-in-one oily solvent additive It accounts for 20-30% of the oily paint, and the three-in-one oily solvent additive is mixed with epoxy resin to make an environment-friendly resin.

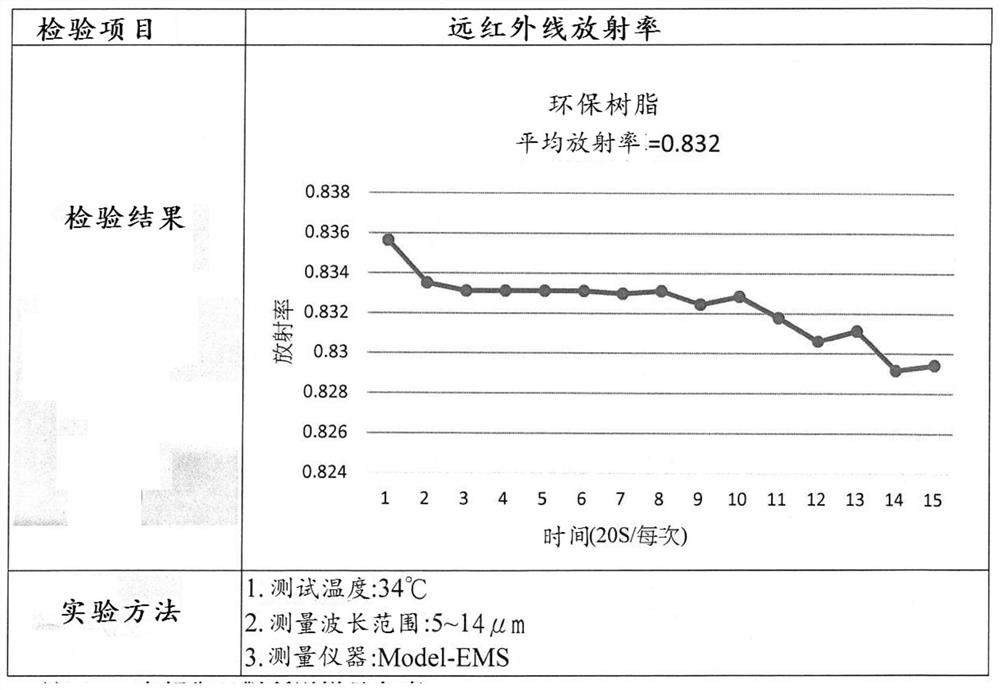

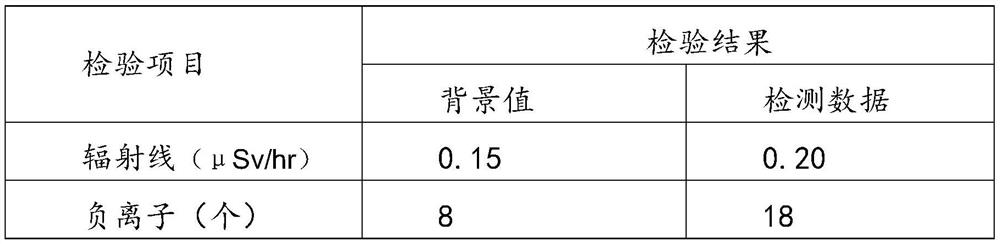

[0049] The obtained environmental protection resin has been tested for far-infrared emissivity, and the results can be found in figure 2 As shown, after detecting negative ions, the results are shown in the table below:

[0050]

[0051] The use of epoxy resin materials can also show the function of nano-sized size effect and quantum size effect to produce health care. At the same time, it can release zinc ions, which has long-term antibacterial properties or resin-made glue and odor, to achieve environmental protection and safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com