Rubber asphalt waterproof coating and preparation method thereof

A waterproof coating and rubber asphalt technology, applied in asphalt coatings, coatings, etc., can solve the problems of chemical reaction deterioration, loss, material performance attenuation, etc., and achieve the effects of slowing down chemical reactions, improving product stability, and enhancing coating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

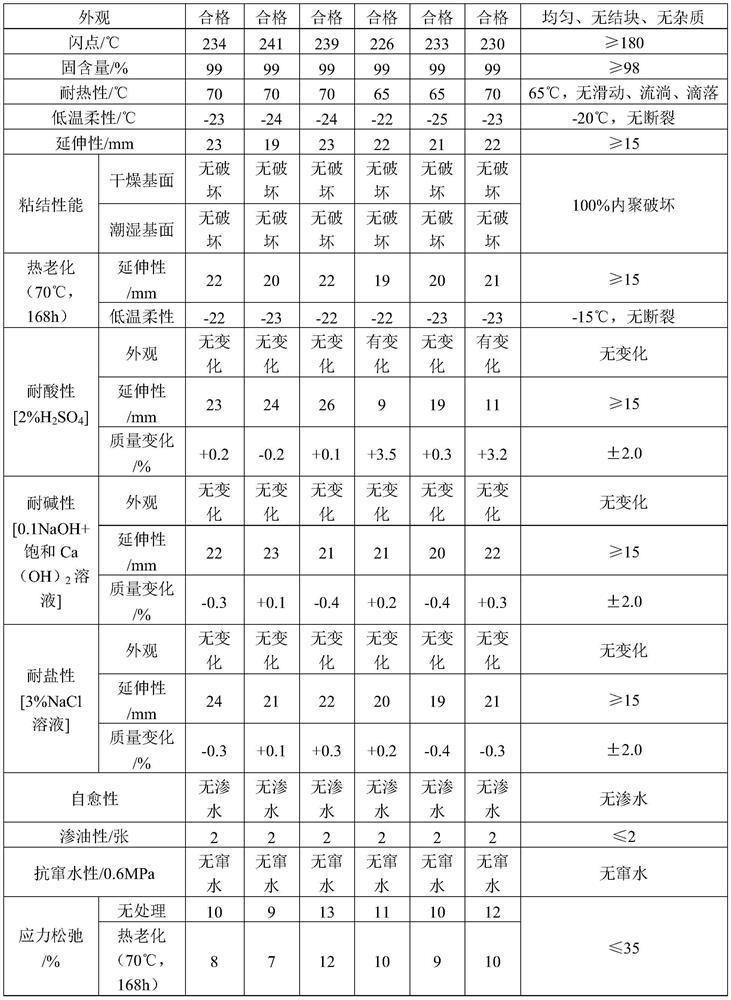

Examples

preparation example Construction

[0022] The preparation method of coating agent of the present invention can be carried out with reference to prior art, preferably, described coating agent is made by following method:

[0023] (1) Heat the second-line distillate oil to 110-130°C and stir evenly;

[0024] (2) Then add petroleum resin in step (1), heat up to 135-145°C, stir and mix evenly;

[0025] (3) Finally, add low-molecular-weight polyethylene wax to step (2), heat up to 150-160°C, stir and mix evenly, and cool to obtain the coating agent;

[0026] Preferably, in step (3), the stirring and mixing time is 90-120min.

[0027] According to the present invention, preferably, the weight average molecular weight of the low molecular weight polyethylene wax is 1000-2200, preferably 1000-1800;

[0028] In terms of parts by mass, the second-line distillate oil is 45-90 parts, the petroleum resin is 1-15 parts, and the low molecular weight polyethylene wax is 1-20 parts; preferably, the second-line distillate oil ...

Embodiment 1

[0060] Put 44 parts of 70# petroleum asphalt and 15 parts of aromatic hydrocarbon base oil KA20 into a high-speed mixer, and stir at 400 rpm for 15 minutes at 140°C; Stir at 700rpm for 30min; after completion, add 3.2 parts of coating agent, and stir at 750rpm at 160°C for 20min; after completion, add 13 parts of SBR, and shear at 160°C at 1500rpm for 40min at high speed; complete Finally, add 0.8 parts of cross-linking agent TAIC, stir at 700rpm at 160°C for 30min; after completion, add 12 parts of 800 mesh heavy calcium, stir at 800rpm at 160°C for 30min; finally, turn on low-speed stirring , under the condition of 160°C, stirring at 400rpm for 40min to prepare rubber asphalt waterproof coating.

Embodiment 2

[0062] Add 45 parts of 70# petroleum asphalt and 15 parts of aromatic hydrocarbon base oil KA20 into a high-speed mixer, and stir at 400 rpm for 15 minutes at 140°C; Stir at 700rpm for 30min; after completion, add 3 parts of coating agent, and stir at 750rpm at 160°C for 20min; after completion, add 12.2 parts of SBR, and shear at 160°C at 1500rpm for 40min at high speed; complete Finally, add 0.8 parts of cross-linking agent TAIC, stir at 700rpm at 160°C for 30min; after completion, add 12 parts of 800 mesh heavy calcium, stir at 800rpm at 160°C for 30min; finally, turn on low-speed stirring , under the condition of 160°C, stirring at 400rpm for 40min to prepare rubber asphalt waterproof coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com